Drop testing of precision mechanics

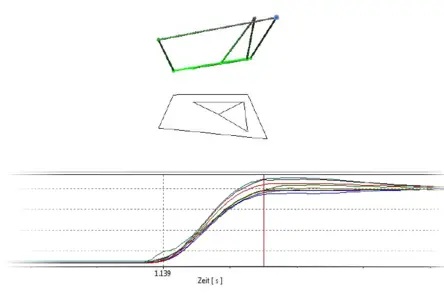

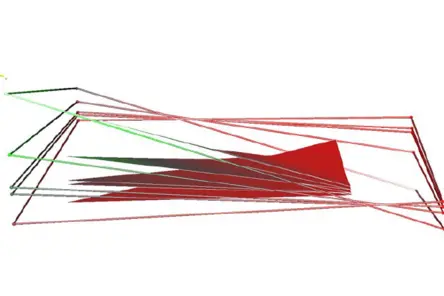

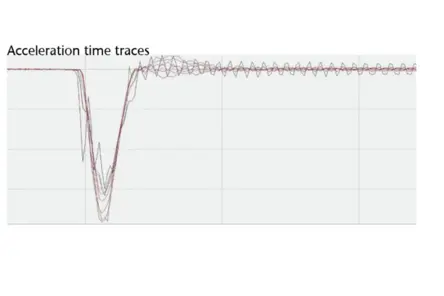

The main objective of drop testing is to analyze the dynamical behavior of sensitive structures during fall and impact. In a specific test, the test specimen of precision mechanics is represented by a watch case (pure watch with removed bracelet), measured during and right after the resulting impact of its free-fall on the ground. In particular, the goal in this drop test is to obtain the displacement, velocity and acceleration profiles for different points from different parts of the case.

Synchronous optical impact measurement

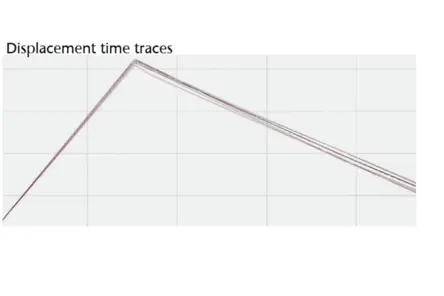

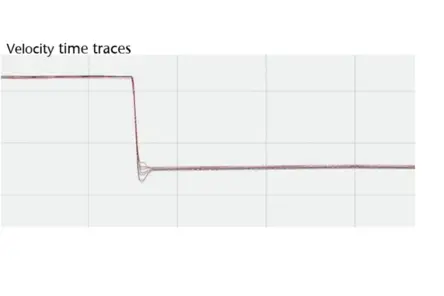

During the measurement the velocity was recorded as a function of the time. The measurement also allowed to record the velocity of the watch case for 8 specific measurement points during approximatively 8 ms; 3 ms before the impact and 5 ms after the impact. An overlay of the velocity traces allows for a comparison of the different measurement points and can be seen in the displacement graph. The graphs also show different behaviors during the impact.

As conclusion, for drop testing and dynamic impact observation the synchronous and non-contact measurement method using a MPV Multipoint Vibrometer is a valuable way to assess the dynamic impact response. The MPV-800 uses independent fiber-optical sensors which can be positioned arbitrarily around the object and – if required – can be combined to 3D channels. A sampling frequency of up to 250,000 samples per second allows to resolve also very short time impacts with a very high precision and resolution. Such results allow for unambiguous post-processing and model updating.

MPV-800 Multipoint Vibrometer for door-slam testing

Synchronous optical vibrometry like possible using a MPV Multipoint Vibrometer enables non-contact and laser precise measurements of transient and time-critical events. See this sample measurement of a door-slam test, enabling engineers to analyze the operational deflection shapes resolved in both the time and frequency domain for optimizing acoustics.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters—get in touch with us today.