The non-contact encoder ProSpeed®

Precise speed and length measurements are critical for controlling the production of continuous materials, sheet materials and piece goods. ProSpeed® – the next generation LSV Laser Surface Velocimeters – optimize production processes by providing reliable measurements and increase the output worldwide in the metals, cable and converting industries.

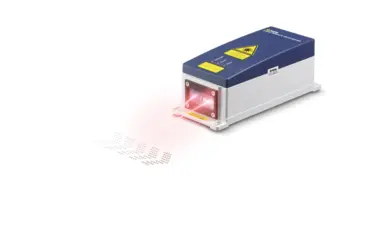

The ProSpeed® LSV-2100 optical sensor determines the direction of motion and standstill conditions with laser precision.

3 year warranty

Polytec stands behind the durability and performance of its optical sensors by offering an industry-leading 3-year warranty including the laser diode. This as well as our strong service & support program reflects our confidence in the quality and longevity of our products.

Highlights

//- Reliable measurement

- of forward and backward motion plus standstill

- Easy process integration

- with long stand-off distances up to 3m

- Outstanding measurement

- depth-of-field up to 200 mm

- Robust sensor technology

- (IP 66, 67)

- Multi-user access

- (3 via Ethernet + 1 serial)

- Visible laser

- for easy alignment

- Transparency

- thanks to enhanced connectivity (web interface, Ethernet, fieldbus protocols)

- Application-optimized accessories

- such as thermo-protective housing, air wipe and air amplifier, cooling plate, beam deflection unit and more

- 36 months

- free warranty

Get in touch with our experts

Get in touch with our experts

Achieve far more in your production process

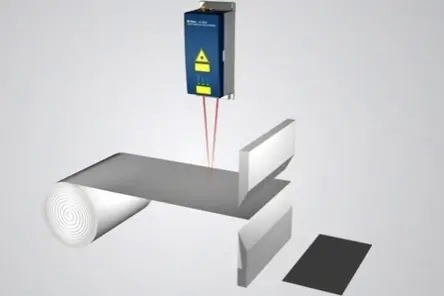

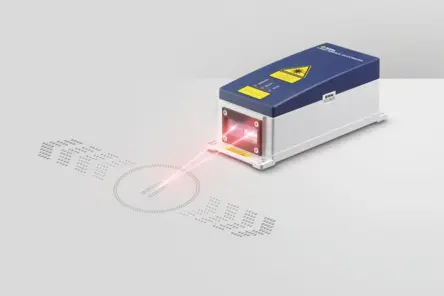

ProSpeed® LSV-2100 optical sensors measure length and speed reliably even under harsh production conditions with large working distances up to 3 m. Due to the non-contact measurement principle, these laser sensors eliminate common problems of traditional contact-wheel measurement methods such as damage to delicate surfaces, slippage and thermal expansion and work on almost any surface.

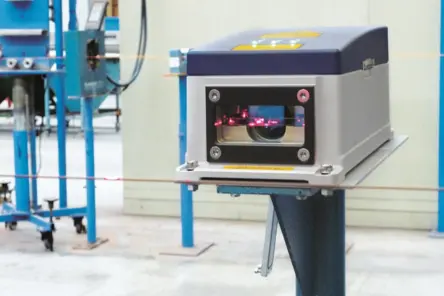

The TPH thermo-protective housing offers additional protection especially for really challenging environments. Application-optimized accessories such as air wipe and air amplifier, cooling plate, beam deflection unit and more enable customized sensor solutions with easy in-line integration.

Simplified sensor integration with enhanced connectivity

The enhanced connectivity concept of the ProSpeed® LSV sensor generation grants access to configuration and process data anywhere and anytime. Enhance your flexibility, enabling direct feedback to machines on behalf of monitoring data through an optional touch display. Parametrize the sensor via web interface with ease and benefit from data access with Ethernet and serial interface for up to four users. For automated PLC-controlled processes, use the integrated PROFINET and EtherNet/IP interfaces which makes sensor integration into any production control systems as smoot and easy.

Inline measurement of length & speed in rolling mills, casting lines & metal plants

Related topics

Get in touch with our experts

Get in touch with our experts

Our experts are ready to support your projects with tailored sensor solutions or support you in measuring what matters — get in touch with us today.