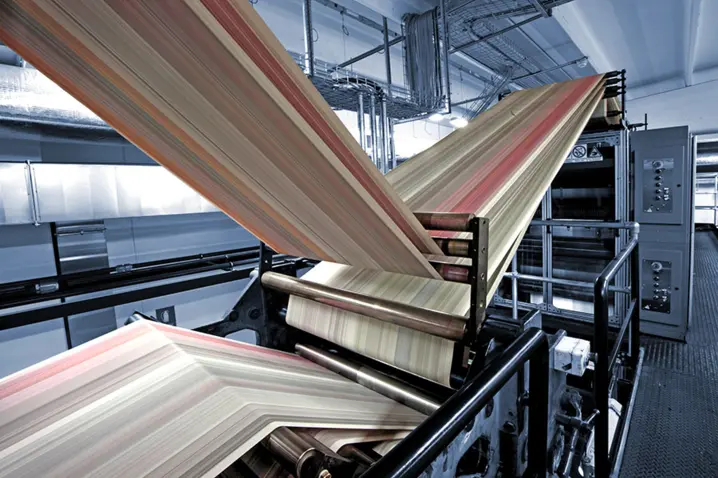

Non-contact detection of velocity and length in converting, plastics and textiles

Accurate and transparent length and speed measurement influences your entire manufacturing and processing for paper, cardboard ond more. Even smallest deviations cause added material costs, and these can quickly add up. This is where non-contact laser precision measurement with LSV laser-based length and speed sensors come into play.

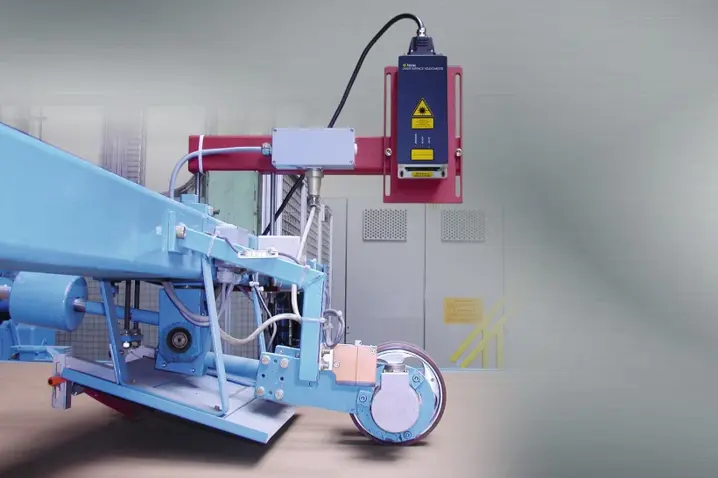

Polytec's Laser Surface Velocimeters (LSVs) have been specially developed for high-precision measurement of length and speed in production processes. LSVs promise reliable measurement data from your manufacturing or packaging process as fundamental data for your process control systems. Relying on LSV lenght and speed sensors means increased measurement precision, leading to optimized quantity and quality of your output. Polytec's non-contact laser sensors works on almost all surfaces and rule out any chance of damaging the product surface like typical for tactile encoding devices. From precision position monitoring in printing processes right through to cutting length control for packaging materials – Polytec systems ensure that you obtain the perfect configuration for every application.

ProSpeed® optical length and speed sensors measure with the utmost reliability in companies all around the world and support manufacturing processes...

- in paper factories

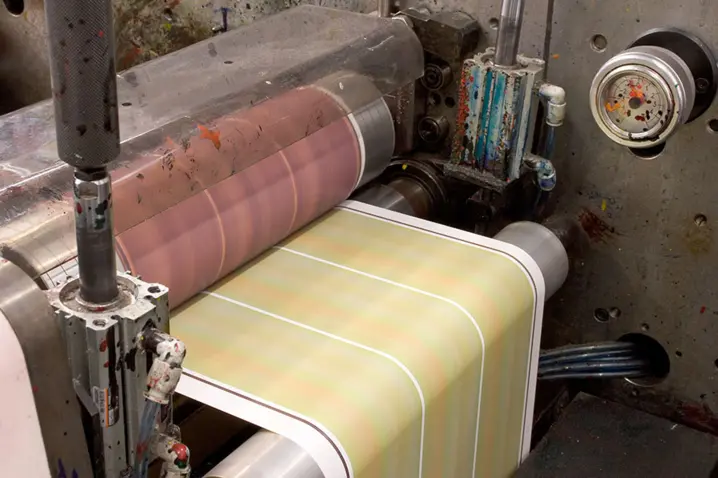

- in printing processes

- and many other paper, cardboard and packaging processes.

Downloads

Cut-to-length and velocity control

Polytec LSVs are used for various tasks in the paper, cardboard and packaging industry:

- winding sheet materials

- measurement of cut lengths

- position sensing in printing processes

Polytec LSVs carry out measurements on materials such as wood, cardboard, film, wire, plastic profiles, construction materials and textiles. One specific example is the length measurement of corrugated board sections.

Practical examples

Polytec LSVs are used for various velocity measurement tasks in the paper, cardboard and packaging industry:

- dwell time determination in coating and surface treatment systems

- cutting device control in cut-to-length processes

- coil synchronization when winding sheet materials

Non-contact LSV velocity sensors in paper production

A Polytec LSV is installed in a paper factory because of frequent downtime when changing rolls of paper in its coating machine. Integrating the LSV into the process control allowed rolling velocities to be aligned exactly with one another with an accuracy of 0.1 %. This resulted in a significant reduction of tension fluctuations when joining the paper webs and has already led to savings equivalent to the investment costs in under a year.

Polytec laser sensors for paper production

In der Papier-, Pappe-, & Verpackungs-Industrie werden LSV von Polytec für unterschiedliche Geschwindigkeitsdifferenzmessungen eingesetzt:

- Synchronisierung von Einzelbändern in Längsschnittprozessen

- Synchronisierung von Rolle und Band in Aufroll-/ und Abrollprozessen

- Spannungskontrolle

Wegen häufiger Ausfälle beim Wechsel der Papierrollen auf einer Streichmaschine hat eine Papierfabrik das LSV von Polytec installiert. Durch dessen Integration in die Prozessteuerung können die Abrollgeschwindigkeiten bis auf 0,1 % genau miteinander abgeglichen werden. Dies führt zu einer signifikanten Verringerung der Spannungsschwankungen beim Verbinden der Papierbahnen und hat bereits in weniger als einem Jahr die Investitionskosten eingespart.

Practical examples

Polytec LSVs are used in various applications in the paper, cardboard, & packaging industry as a means of controlling cut lengths of paper and cardboard products. Polytec LSVs carry out measurements on materials such as wood, cardboard, film, wire, plastic profiles, construction materials and textiles. One specific example is the length measurement of corrugated board sections.

Position tracking of labels and marks

Polytec LSVs are used in the paper, cardboard and packaging industry for determining positions in printing processes. Length measurement can trigger a working step at regular intervals in the process, e.g. printing labels or attaching lettering and logos.

Practical examples

Polytec LSVs are used in various applications in the paper, cardboard, & packaging industry as a means of regulating tension:

- in joining sheet materials, i.e while changing rolls of paper

- when processing sensitive material such as thin paper

Non-contact LSV velocity sensors in paper production

A Polytec LSV was installed in a paper factory because of frequent downtime when changing rolls of paper in its coating machine. Integrating the LSV into the process control allowed rolling velocities to be aligned exactly with one another with an accuracy of 0.1 %. This resulted in a significant reduction of tension fluctuations when joining the paper webs and has already led to savings equivalent to the investment costs in under a year

Industrial length and speed control with optical sensors

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters — get in touch with us today.