Optical measurement of dynamic stress and strain

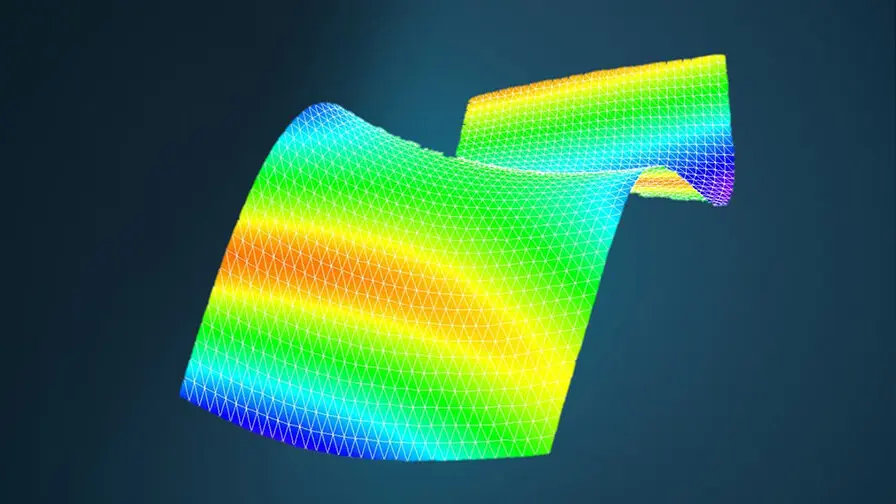

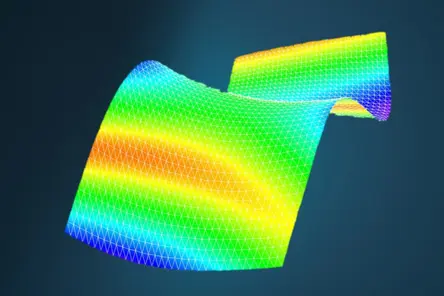

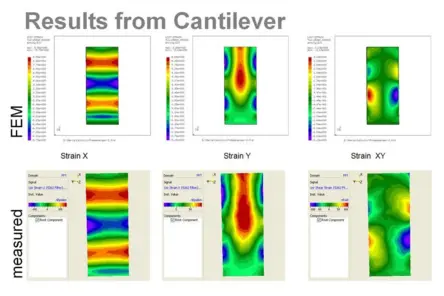

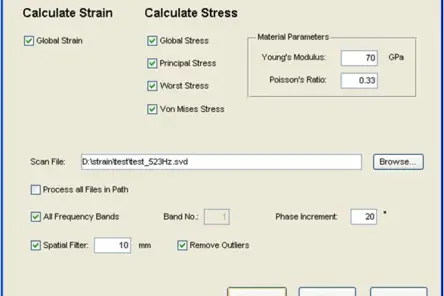

Understanding the origin of the stress and strain distribution is crucial to increasing the durability of components under dynamic load. Numerical simulations based on finite element (FE) models help with this understanding but must be validated by real component data. Polytec’s 3D Scanning Laser Doppler Vibrometer with strain processor provides an advanced, non-contact optical test solution.

The package of strain processor in combination with a VibroScan QTec Xtra 3D Scanning Vibrometer allow a non-contact, optical measuring alternative for dynamic stress and strain distribution and Finite Element model updates.

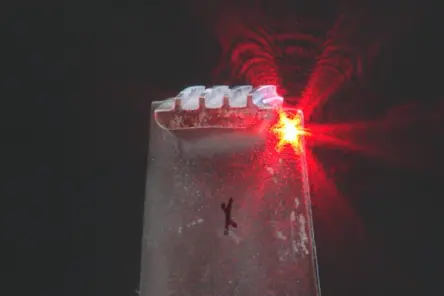

The scanning vibrometer makes a series of non-contact deflection measurements on a predefined grid using the laser probe to characterize strain at each point instead of attaching individual strain gauges. Thus, the test set-up is fast and very repeatable with no mass loading from an attached transducer. Tests are fast and avoid the high cost of preparing and instrumenting the sample with strain gauges.

Get in touch with our experts

Get in touch with our experts

Let’s talk! We will find the right solution for your needs.

Highlights

//- Non-contact strain measurement revealing the true strain distribution

- Quick setup and fast results

- No mass-loading, stiffening and damping

- High spatial resolution to measure local strain at no additional cost

- Variable field-of-view for different object sizes

- Measure using arbitrary points or FEM geometry for model validation

- Full-field method allows direct visual comparison to FE results

Related products

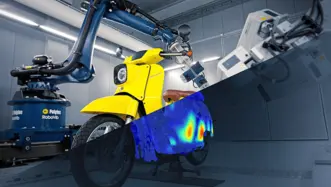

RoboVib®

By combining a 3D scanning vibrometer and an industrial robot, RoboVib® forms an automated test station for measuring everything from complex components to complete vehicle bodies. Reduce testing time and expenses as well as time to market significantly in experimental modal analysis. Conduct comprehensive 360° testing of a vehicle body, for example, within only one-two days and overnight instead of weeks of preparation with conventional test setups.

Measurement service & rentals

Our engineering services cover a wide range of applications, either onsite or in our laboratories. Ask for our PolyXperts, rent cutting edge laser measurement equipment and benefit from individual support for your projects. Our experienced application engineers are pleased to help, measure and test for you. For comprehensive studies, rent the RoboVib® Structural Test Station