Control your cut length, shearing or cropping processes

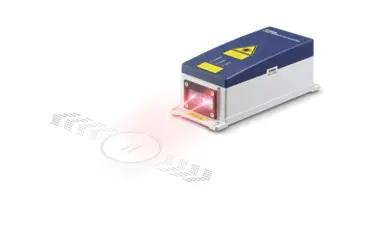

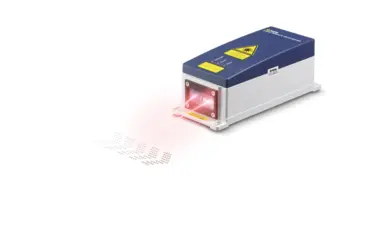

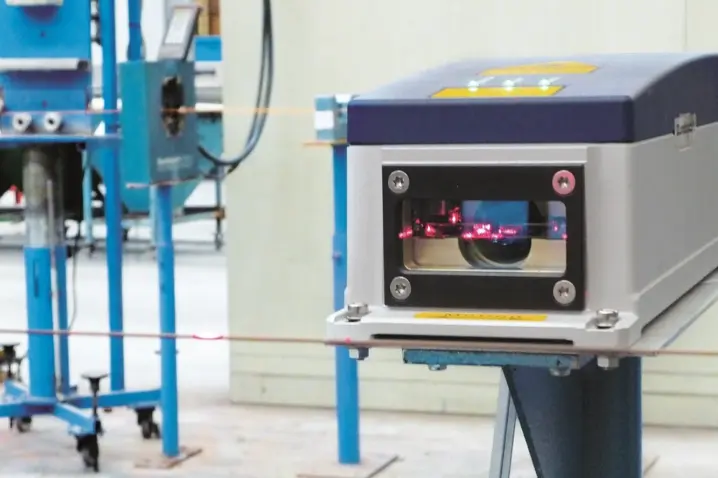

Polytec’s Laser Surface Velocimeters ProSpeed® are reknown non‑contact sensors, or optical encoders, for precise cut‑to‑length and cutting control – whether in metals, wood and construction materials like mineral wool or drywall boards, paper and packaging, plastics and converting processes, or cable & wire all over the world. The laser sensor replaces contact wheels/ and encoders, eliminating slippage and wear, saving material by tightening length tolerances, allowing smaller safety margins. Last but not least Polytec sensors increase accuracy and yield – cut by cut, shift by shift.

- Length and process feed monitoring for continuous and piece goods like webs, boards, bars, tubes, slabs or panels.

- Cut‑length control for stationary or flying saws on wood, shears in converting, knives, slitters in plastics and textiles, or rotary tube saws.

- Length verification of cut products and material tracking for downstream operations or quality allocation.

Controlling cutting, shearing and cropping in sync with the true process speed

In practice, the same sensor often handles several tasks at once: measuring true line speed, triggering pre‑warning or cuttting signals, and synchronizing moving elements like flying saws with the product. For example for steel, plastic, or paper, LSV help synchronize the cutting tool with the material's speed.

LSV laser sensors measure process feed and the velocity of your production on almost any material including in challenging dusty, dirty production and on red hot steel. Its non-contact speed measurement avoids slippage and wear like known from classic encoders or drives. LSV optical sensors avoid any influence on the product surface and can easily be integrated into your PLC and production systems with all common interfaces, LAN, ProfiBus or ProfiNET etc.

Cut-to-length in steel & metals

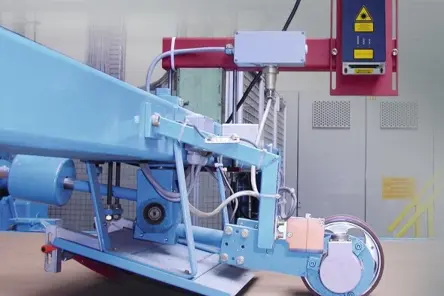

- Hot and cold, flat, long and round products

- Synchronization of vertical shears, slitting lines, flying saws and rotary tube saws

- Torch cutting on billets, slabs or blooms

- Cutting of heavy steel plates, thin or trapezoidal sheets and profiles

- Crop optimization with flying guillotine shears

"The LSV Laser Surface Velocimeter by Polytec has provided us with process-reliable and highly accurate speed and length information - even under the most difficult environmental conditions. This makes the LSV laser sensors the perfect matching sensor technology in tube rolling mills"

Advantages

//- Avoid slippage and wear

- with non-contact, optical cut to length control

- Higher accuracy, increased yield

- Laser-based cutting allows reduced safety margins, producing less scrap and reliable output

- Compensate "jumping" material and varying distances

- with outstading measurement depth-of-field up to 200 mm and large stand-off-distances

- Easy sensor integration

- into PLC with enhanced interface concept like Ethernet, fieldbuses, multi user etc.

- Measure on any surface

- laser principle masters challenging shiny, dusty, oily or red-hot materials

- Application-optimized accessories

- like thermo-protective housing, air wipe and air amplifier, cooling plate, mounting and adjustment platform, beam deflection etc.

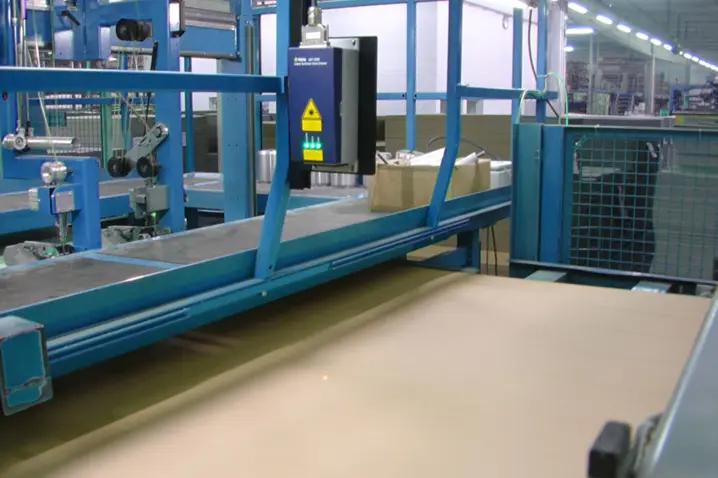

Cut to length of construction and insulation materials & wood

- Cut length of products sold by length like mineral wool, glass wool, insulation

- Drywalls or gypsum boards, plasterboards

If a product line does not stop during the cutting process, the cutting or shearing device as to be moved as a flying cutting device in sync with the line speed for a straight cut. LSV optical sensors help synchronize the shearing device with the product by simultaneously measuring and providing length and speed parameters to the production system.

Shearing & length cutting on paper, cardboard & corrugated boards

- Cut‑to‑length control for paper and cardboard webs, including corrugated board lines

- Controlling the cut length and speed of cardboards and packaging material

Cut length of cables & wires or fibers

- Polytec LSVs are used in the cable and wire industry to control cutting lengths on cables and wires

- Cut length of sheathing and insulation materials.

"With the measuring accuracy being independent of the line velocity, even the slightest movements can be measured. This is key for our cable & wire applications. The measuring system is easy to integrate into production processes and the visible laser really simplifies the alignment within the large measuring field."

Cut length in extrusion, converting & plastics

- Length/speed monitoring and cut control for plastic film, extruded profiles, sheets and other converting products.

- Non‑contact encoder function for dwell‑time control in coating or laminating processes.

Compared to contacting encoders, users gain more stable length at high speed, better repeatability when the weight, coatings or surface textures change, and no wheel‑markings on sensitive surfaces.

Optical length & speed measurement for ultimate precision process control

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters — get in touch with us today.