表面計測に関するノウハウ

Polytec 誌における表面計測技術:

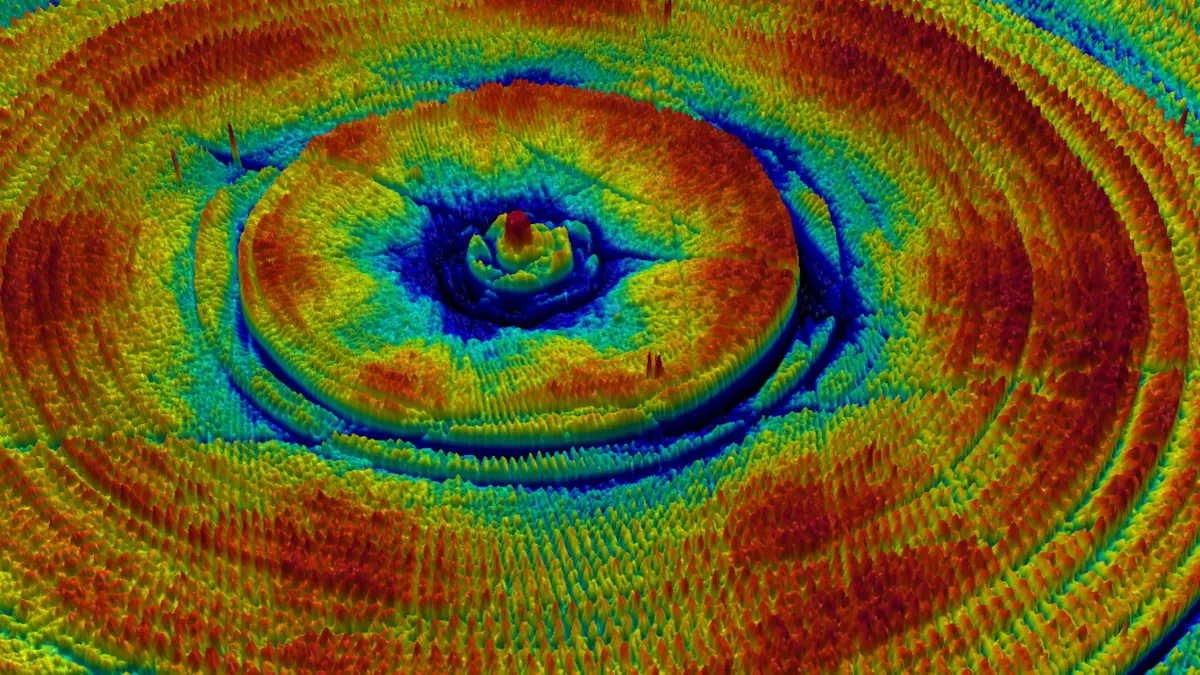

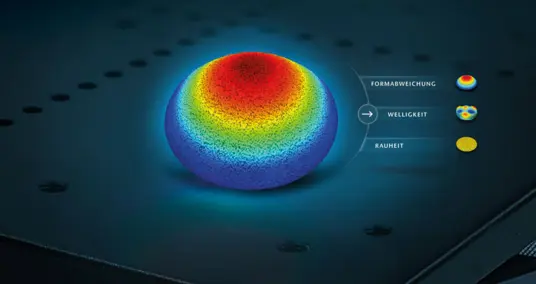

How CSI technology retrieves superior topography, form & roughness measurement data

Read how the optical technology of Coherence Scanning Interferometry (CSI) analyzes topography, form & roughness, where are sweet-spots, benefits and applications compared to related optical surface inspec…

Characterizing surface texture, roughness, imperfections and scratches

Optical polishing is a fabrication technique developed specifically to achieve minimal defects and smooth micro-roughness values. Polishing is a process that involves the use of free grains, usually suspen…

Interview with Prof. Dr. Albert Weckenmann about optical and tactile surface measurement technology

We talked with Prof. Dr. Albert Weckenmann of the University of Erlangen-Nuremberg, Germany, about the limitations of tactile surface measurement technology and the opportunities of non-contact methods.

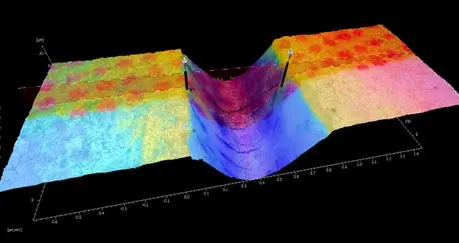

Confirm flatness, roughness and step height – TopMap quality control on the factory floor

Consistently producing high-quality precision parts is better achieved when the supporting metrology is tightly integrated with the manufacturing process. By combining Polytec’s TopMap optical metrology wi…

Overview of optical methods for surface metrology

For applications where tactile surface measurement techniques have shortcomings, non-contact optical instruments have been developed to overcome these shortcomings. Especially with the development of compu…

How surface metrology reveals the finest forensic details

Forensic science plays a vital role in the criminal justice system by providing scientifically based information through the analysis of physical evidence. During an investigation, evidence is collected at…

For permanently high screw pre-tensioning force and optimum corrosion protection

The surface properties of coatings and paintwork play an important role in many products, as they have a significant impact on visual appearance, corrosion protection and resistance to physical damage. Inf…

ご要望について専門家とご相談ください

まずは部品仕様、公差、ワークフローについて簡単に話し合いましょう。必要に応じて、実現可能性調査、PolyMeasure(契約測定)、またはPolyRentトライアルをオプションの次のステップとして追加することも可能です。