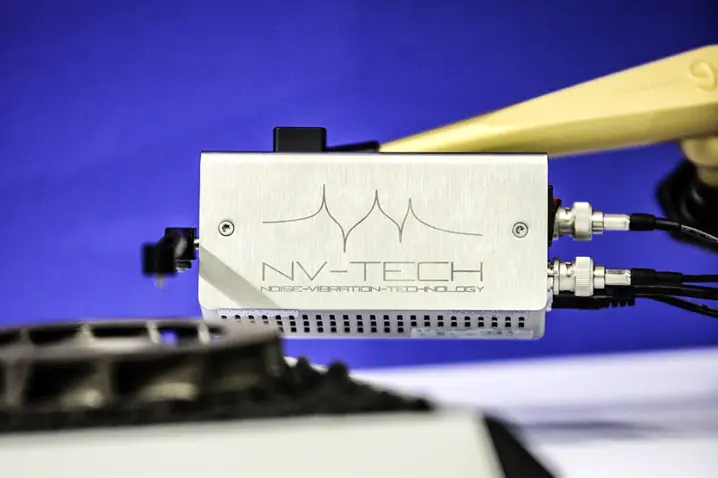

Precise excitation without mass-loading

To achieve consistent transfer functions in experimental modal tests, an excitation source with repeatable force level is key. The unrivalled repeatability of the SAM Scalable Automatic Modal Hammer perfectly matches PSV Scanning Vibrometer needs. Two models allow for excitation of small and large structures with force ranges up to 222 N and 2.200 N. Use the SAM Scalable Automatic Modal Hammer for precision excitation without mass-loading in modal testing and modal analysis.

Get in touch with our experts

Get in touch with our experts

Let’s talk! We will find the right solution for your needs.

Highlights

//- Repeatable excitation avoids double hits

- Precise force level control enables structural linearity checks

- Reproducible position and angle for consistent transfer functions

- Bandwidth > 40 kHz for lightweight structures

- Force levels from 1 N to 2200 N also excite large structures.

- Adjustment of the operational hit angle to excitation from all directions

- External trigger option for acoustic quality control

- Expanded operating temperature range from -20 up to 120°C (-4° .. 248°F) for climate chambers etc.

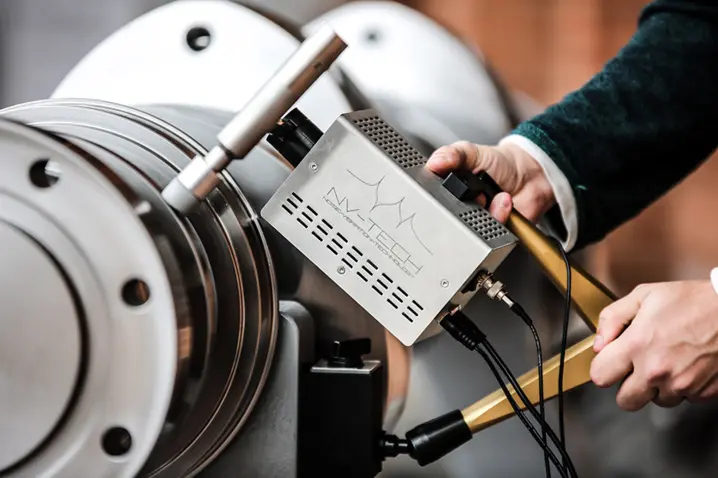

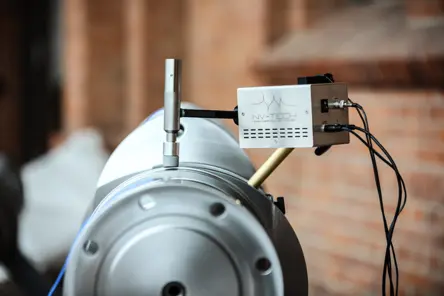

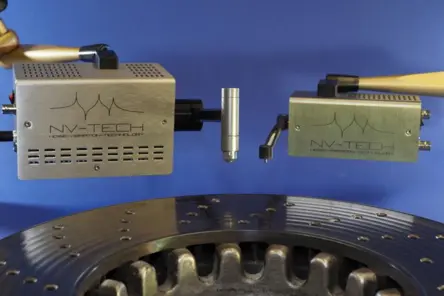

Automatic excitation for modal testing

The Scalable Automatic Modal Hammer type SAM1 is a tripod mountable actuator for sample excitation in experimental modal analysis and acoustic quality assurance with force levels up to 222 N, specially designed for lightweight structures and confined spaces. The software-controlled stepper motor allows for a high definition control of all relevant parameters and the travel of the hammer arm featuring the integrated force transducer.

SAM3 is designed for the excitation of larger samples in experimental modal analysis and acoustic quality assurance with force levels up to 2200 N. The software-controlled stepper motor allows for a high definition control of all relevant parameters of the impact of an instrumented modal hammer.

The SAM GUI Professional is used for convenient parameterization of the automatic modal hammer. Application-oriented features, such as the control of the impact angle or a remote control for precise set-up, enable practically every test setup.

Downloads

Related products

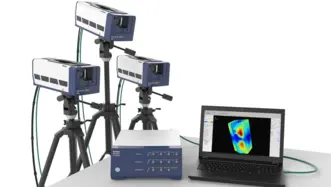

VibroScan QTec Xtra

VibroScan QTec Xtra measures vibrations in a new way - without contact, full-field and with unprecedented precision. With its groundbreaking multi-path interferometry, QTec® sets new standards in terms of optical sensitivity and interference immunity. The Xtra, based on an infrared (SWIR) laser is characterized by the highest optical sensitivity to guarantee highly accurate measurements even on demanding technical surfaces. VibroScan QTec Xtra ensures maximum portability through integrated data acquisition and signal generator up to 32 MHz.

VibroScan QTec Xtra 3D

VibroScan QTec Xtra 3D measures vibrations triaxially in a new way - without contact, full-field and with unprecedented precision. With its groundbreaking multi-path interferometry, QTec® sets new standards in terms of optical sensitivity and interference immunity. The Xtra, based on an infrared (SWIR) laser is characterized by the highest optical sensitivity to guarantee highly accurate measurements even on demanding technical surfaces. VibroScan QTec Xtra 3D ensures maximum portability through integrated data acquisition and signal generator up to 32 MHz.

VibroScan QTec Neo

VibroScan QTec Neo measures vibrations in a new way - without contact, full-field and with unprecedented precision. For the first time, QTec® technology has been successfully transferred from the infrared SWIR laser to the visible helium-neon laser. Featuring a small laser measuring spot, the precise helium-neon laser is suitable for measurements on the finest structures and even measures in and through water. QTec® always ensures a stable signal and the best signal-to-noise ratio. VibroScan QTec Neo ensures maximum portability with integrated data acquisition and signal generator up to 32 MHz.

RoboVib®

By combining a 3D scanning vibrometer and an industrial robot, RoboVib® forms an automated test station for measuring everything from complex components to complete vehicle bodies. Reduce testing time and expenses as well as time to market significantly in experimental modal analysis. Conduct comprehensive 360° testing of a vehicle body, for example, within only one-two days and overnight instead of weeks of preparation with conventional test setups.