Non-contact measurement in tube & pipe production

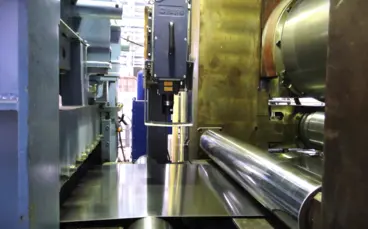

Polytec optical sensors are widely used in tube production, measuring tube / pipe speed, for position tracking or NDT, laser precise cut-to-length control and in general for non-contact length and speed measurement. LSV (short for Laser Surface Velocimeter) monitor length and material on longitudinally welded pipes and also reliably measure the rotational speed of seamless pipes. Avoid process uncertainty and added costs introduced by contact measuring techniques due to slippage, wear, damage to the product or increased maintenance requirements.

Why use optical sensors for tube & pipe process control

ProSpeed® LSV (short for Laser Surface Velocimeters) are the ideal non-contact sensor solution in tube and pipe manufacturing, whenever precise and real-time speed and length data is decisive. Using optical sensors in pipe production leads to reduced costs due to less material scrap and optimized process quality.

ProSpeed® optical sensors are easily integrated replacing less accurate and less reliable encoders or tachometers for tube and pipe production. Savings in reduced downtime and maintenance as well as increased product consistency provide an excellent ROI on Polytec optical sensors.

Benefit from optical measurement with ProSpeed® sensors

Applications of optical sensors in steel tube processes

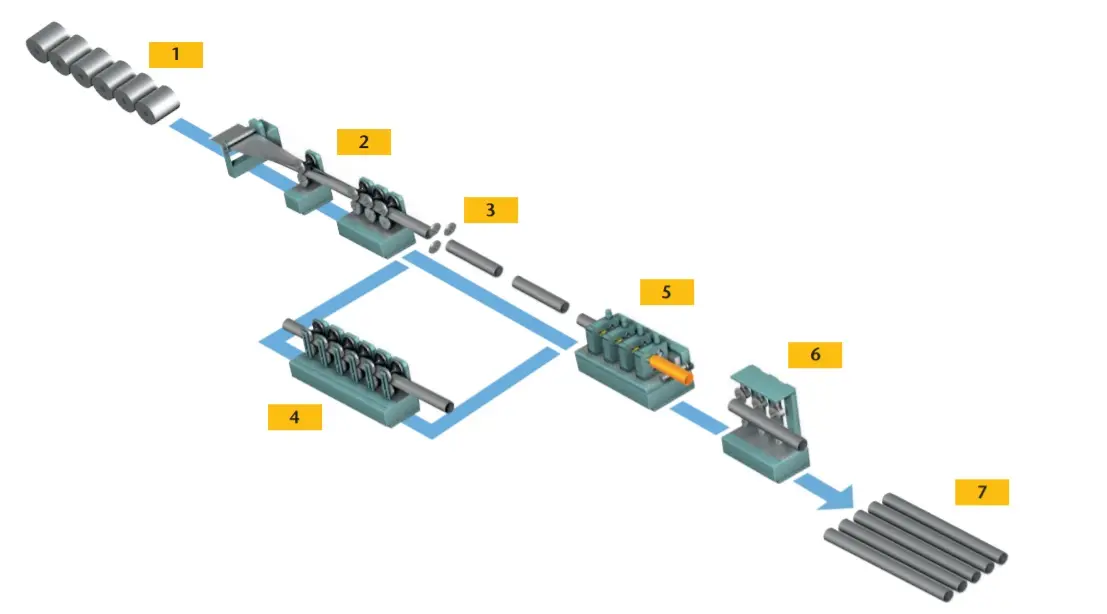

There are many measurement applications for Polytec LSV laser sensors in the production of (stainless) steel pipes and related tubes:

Monitoring and synchronizing the coil feed speed in the forming section

Pipe speed measurement in welding

Superior cut-to-length control directly reduces scrap and optimizes yield

Precises pipe speed monitoring through the temper / quench area

Position tracking and crop shear control in the stretch reducing mill

Final length control and length verification at the stencil area.

Defect tracking in NDT (Non-desctructive Testing)

Where do you measure length or speed in your tube & pipe process?

Contact our PolyXperts!

For decades, we at Vallourec trust on Polytec's laser-optical sensor technology for length measurement and control in our production process of seamless tubes and profiles. Used in harsh industrial environments, the Polytec devices work very reliably even in non-air-conditioned factory halls. Temperatures of the measured material can be at outside temperature or at up to 1000°C. The sensors are an essential support of our process reliability.

How it works: Laser precision for reliable process control

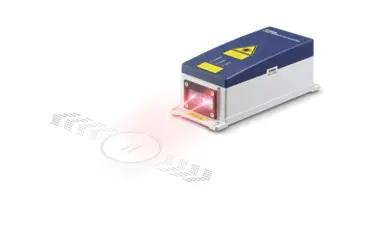

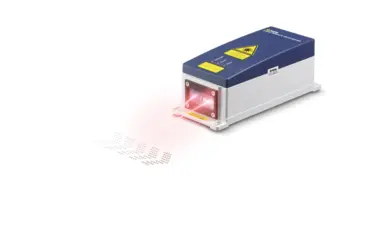

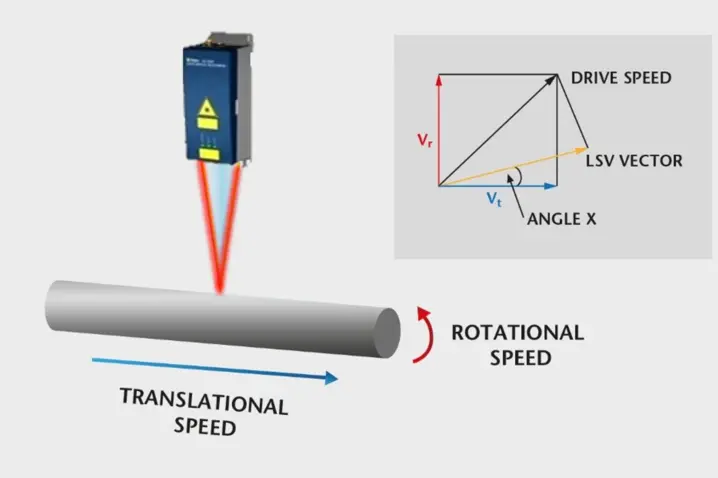

ProSpeed® as the optical alternative sensor solution compared to encoders or encoder wheels use the laser Doppler effect to evaluate the laser light scattered back from the moving object. Two laser beams super-imposed on the surface generate an interference pattern of bright and dark fringes. As the surface moves through the fringe pattern, the intensity of the light scattered back modulates in frequency. This modulation frequency measured by the photo receiver of the sensor system is directly proportional to the surface velocity.

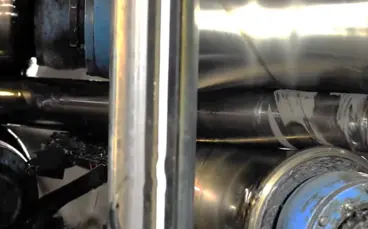

NDT of seamless steel tubes

During NDT the tube should be tested to 100% regarding e.g. metallurgical properties and length. The probe conducting this test is stationary, hence the tube is not just pushed forward, but it also rotates on a spiral path. Any flaw detected needs to be described in its longitudinal and rotational position. Here, the non-contact LSV laser sensor comes into play: Being insensitive to out-of-plane motions, it is the preferred optical solution for such setups. One unit keeps track of the longitudinal progress while a second unit monitors the rotation. Specialized accessories for such demanding application master electromagnetic inspection (E.M.I.), magnetic powder inspection (MPI), and other test methods.

Sensor integration using PROFINET or Ethernet/IP

The latest ProSpeed® LSV sensor generation comes in a rugged, compact design featuring integrated optics and advanced electronics, providing faster signal response, and more stable signal level for real-time process control. The extended connectivity concept enables a smooth sensor integration into any production line. With a wide range of accessories like beam deflection, air purge or thermo-protective housing - and with the personal support of our PolyXperts team, Polytec offers custom sensor solutions for tube & pipe applications.

For further info regarding sensor integration, read the step-by-step application guides on how to easily integrate ProSpeed® laser encoders with PROFINET or EtherNet/IP. Have a look at the sensor specifications, sign up or just contact us!

The LSV Laser Surface Velocimeter by Polytec provides process-reliable and highly accurate speed and length information - even under the most difficult environmental conditions. This makes the LSV laser sensors the perfect matching sensor technology in tube rolling mills,"

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters — get in touch with us today.