Superior roll gap control by laser precision

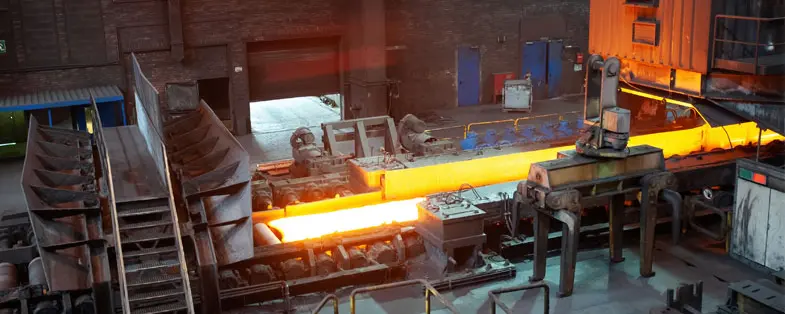

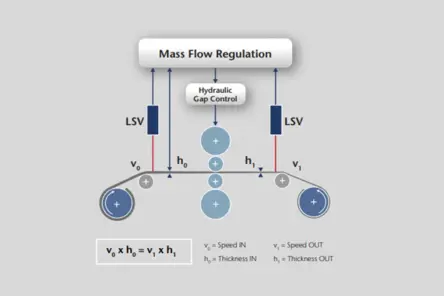

In steel rolling mills, the thickness of the finished coil is an essential quality parameter: Controlling the roll gap plays the crucial role in achieving the specified thickness tolerance throughout the length of the coil. Non-contact, optical sensors for precise material speed measurement at the entrance and exit of the roll stand enable fine adjustment of the roll gap for dynamic process optimization.

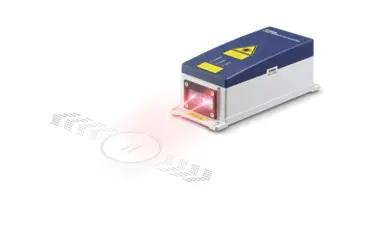

Laser Doppler based sensors like Polytec’s ProSpeed® LSV (Laser Surface Velocimeter) help to improve thickness control and product quality by allowing for enhanced roll gap control, especially during periods of acceleration and deceleration.

Get in touch with our experts

Get in touch with our experts

Our experts are ready to support your projects with tailored sensor solutions or support you in measuring what matters — get in touch with us today.

Definition of roll gap & control in the rolling mill

The roll gap in cold and hot rolling mills refers to the space between the rolls in a roll stand in which the forming of the rolled material depending on the roll gap force takes place. The setting of this gap is crucial for the roll gap force, determining the thickness of the rolled metal (e.g. rolled steel sheets, rolled flat bar or rolled steel tube). Controlling the height of the roll gap, often supported by precise metrologyusing laser technology, allows direct control over the material thickness and speed.

Effective roll gap control requires a combination of precise thickness and speed measurements at the entrance and exit of the roll stand. Automatic Gauge Control (AGC) is a well established technique for precise control of the roll gap in Tandem, Reversing and other types of Rolling Mills. This technique has enabled better thickness control throughout the length of the coil, a higher level of quality repeatability from coil to coil and improved process effeciency.

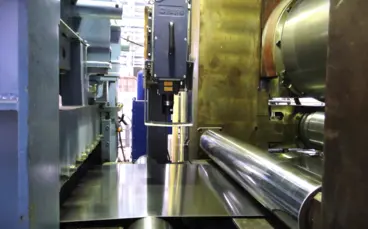

Measuring roll gap and strip thickness

Measuring the strip thickness is conducted by using C-frames, while the speed is being measured in front of and behind the roll stand using a Laser Surface Velocimeter (LSV). With its compact sensor design, the LSV simplifies the integration into the C-frame, saving additional installation work. As the velocity measurement is highly accurate, this combination of strip thickness measurement and LSV allows the required rolling force to be predicted more accurately and the thickness specification of the end product to be better adhered to. This improves quality and therefore increases productivity.

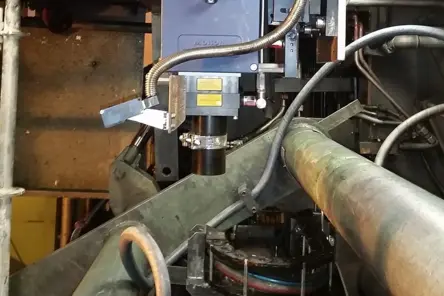

Controlling the roll gap width with laser sensors

Roll gap control benefits significantly from the use of Polytec's LSV Laser Surface Velocimeters. LSVs measure the strip speed highly accurately and reliably on many surfaces from glossy to matt according to the laser Doppler velocimetry. Even on dirty or oily surfaces, the LSV provides a stable measurement signal for process control. In contrast to alternative measuring methods, the LSV does not experience any slippage or wear, which means that the roll gap can be precisely adjusted without being affected by the material.

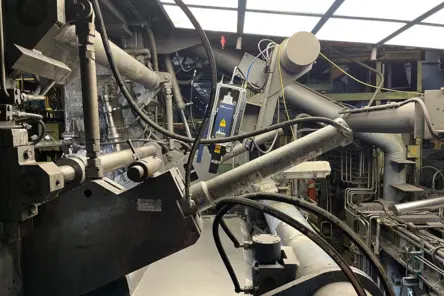

Controlling the roll gap via skin pass and stretching degree

The control of the roll gap during cold rolling is decisevely influenced by the precise measurement and control of the strip speed at the infeed and outfeed of the roll stand. Mechanical contact based tachometers are traditinoally used for this purpose. However, contact methods of measureing strip speed are susceptible to slip and wear, resulting in measurement errors – especially evident during acceleration and deceleration.

These precise measurements become the basis for fine-tuned control of the roll gap, showing significant influence on the mass flow control. By using this optical measuremen technology, major stainless steel manufacturers worldwide had proven to significantly improve the accuracy of their roll gap control, achieving a reduced measurement uncertainty of the skin pass degree down to ± 0.02 %!

Automatic Gauge Control for mass flow control

Elongation is achieved through the temper/skin pass mill. Unlike tandem mills, which are designed for major reduction, temper/skin pass mills are designed to achieve the desired specifications for flatness, surface finish & quality, as well as final mechanical properties of the strip. Elongation control can range from roughly 0.25% to 4% depending on specifications and is controlled, similarly, by measuring and comparing the entry speed and exit speed of the mill.

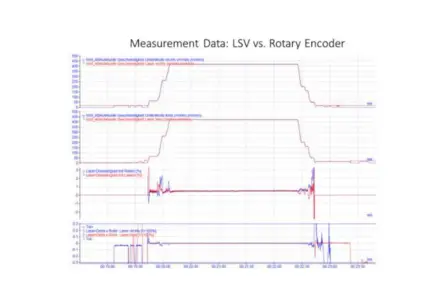

The advantage to using LSV’s is the improved strip speed measurement for mass flow calculations and elongation measurements. The following graph shows a comparison of speed as measured by a Polytec LSV and that of the deflector roll encoder.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters — get in touch with us today.