Precise length & speed monitoring for wood & construction materials

In the wood and construction materials industry, it is key important to monitor length and speed precisely and reliably for maintaining manufacturing tight tolerances and process efficiency. Slight deviations may already lead to additional costs.

ProSpeed® LSV are laser-optical sensors for measuring both length and speed with laser precision, delivering precison measurement data for manufacturers and machine builders for wood and construction materias, such as...

- Quality control and sorting of lumber

- Feed speed and cut-to-length control of piece goods such as insulation materials, glass or rock wool

- Length verification, e.g. of paster or gypsum boards

- Position tracking, e.g. for labeling, marking or NDT

Downloads

Benefit from ProSpeed® optical sensors

- Non-contact measurement, without slippage & wear

- Laser measurement increases accuracy, quality & output

- Works on all surfaces without affecting the product surface

- 3-year warranty & application support

- Large depth-of-field compensates vibrations

- Reliable performance in dusty, dirty environment

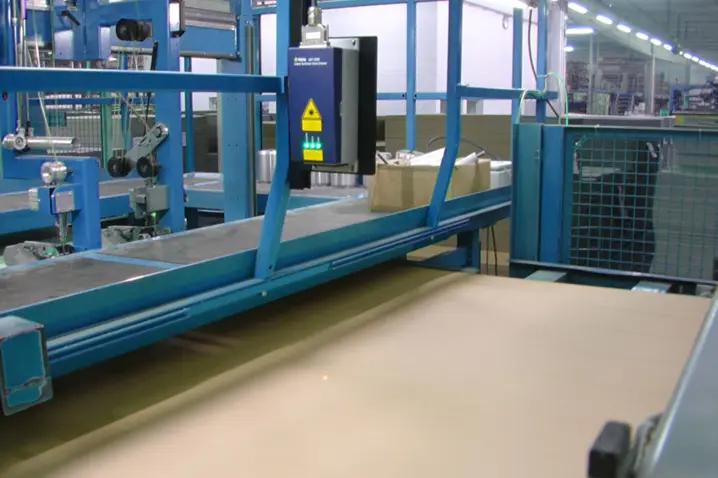

Measure length without slippage

LSV promise reliable length length measurement based on following the speed curve over throughput time. They automatically detect when material is present (material detection mode) and automatically trigger or stop the measurement procedure. LSV Laser Surface Velocimeters are the preferred solution for precise length measurement when rolling up web material and checking cut-to-size pieces, e.g. for fiber cement, plasterboard, wood and wood products, glass wool, rock wool or roofing materials.

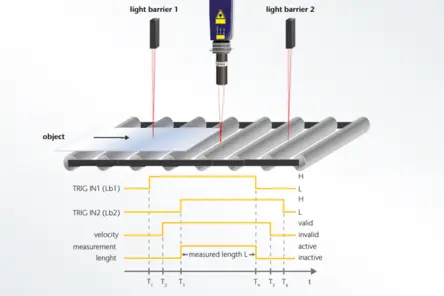

The flexible interface concept of latest generation ProSpeed sensors feature encoder output, serial interface, LAN, Ethernet/IP, Profibus and Profinet. Optionally integrated light barriers and, for several barriers, logically link them, for example, to control the length measurement using two trigger inputs thus increasing the accuracy.

Feed speed as key parameter

Measuring the exact and real speed is the fundament for any process control and optimization - whether for cut-to-length, length measurement or verification, or speed synchronization. With the non-contact measurement method, ProSpeed® laser sensors avoid measuring uncertainty caused by slippage and wear. LSV sensors are established non-contact encoders for determining the dwell time in coating systems, for controlling cutting devices in cut-to-length processes, such as wooden panels, boards and beams as well as in the manufacture of plasterboards, glass or rock wool.

Position tracking on point

LSV laser surface velocimeters measure the length that the measured material travels until a defined event occurs. This measured length determines the corresponding position on the material to be measured, for example when detecting defects in non-destructive material testing (NDT), e.g. on sawn timber and natural products. LSVs also help with exact positioning at regular intervals, such as for printing, labeling, applying lettering or marking damaged areas.

Laser precise cut-to-length control

If a web product is not to be stopped during the cutting process, the cutting device must be moved as a "flying cutting device" for a straight cut with the web product. LSV laser sensors help with speed synchronization between the web material and the cutting device by simultaneously recording the length and speed parameters and outputting them on different interfaces. Regardless of the surface and harsh process environment with dust, dirt and particles, the non-contact measurement method measures with high precision and consistency without repercussions on the material surface.

Thanks to more precise cuts, safety margins on the desired length are reduced, which leads to direct material and cost savings. In addition to encoder output, the flexible interface concept also includes serial interfaces, LAN, Ethernet/IP, Profibus and Profinet as well as digital outputs, e.g. as pre-warning signals and triggers for the cutting process. LSV sensors are used in many different cutting processes, e.g. for wood and wood products, plasterboard, glass wool, rock wool and other building materials.

Industrial length and speed control with optical sensors

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters — get in touch with us today.