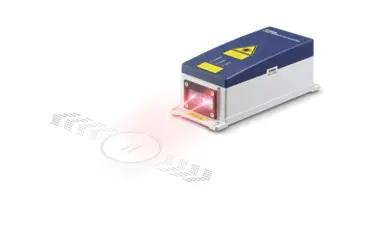

Roll-fed material and piece goods velocity measurement

Velocity measurement is indispensable for process control and optimization in many industrial processes. It is the basis for countless other applications such as cutting length control, length measurement, velocity difference. In these processes velocity is measured using the laser Doppler technique.

Laser surface velocimeters (LSVs) from Polytec are ideally suited because they can conduct measurements on almost any surface and they are not susceptible to contaminated surfaces. The non-contact measuring technique makes it possible to eliminate any negative influences on accuracy, such as slippage and wear, simultaneously. The product being subjected to the measurement also remains intact. Another plus point of Polytec systems is the flexible interface concept which enables velocity readings via encoder output, serial interfaces, LAN, Profibus and Profinet.

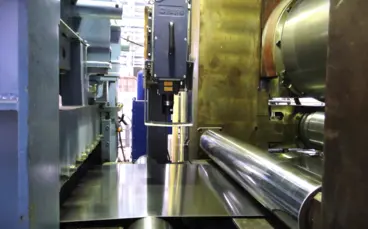

C-micrometer in rolling mill with integrated velocity measurement

The downstream manufacturing industry also has high standards when it comes to the dimensional accuracy and quality of steel and aluminum products used. With a view to continually reducing the thickness tolerances of rolled strips, modern rolling mills are regulated using the mass flow principle. Laser surface velocimeters (LSVs) are easy to integrate and enable reliable measurement of speed components.

Synchronize speed in aluminum production

In the largest aluminum smelting and rolling plant in the world, the length and velocity of aluminum sheets in the manufacturing process are measured simultaneously using non-contact laser Doppler measurement technology from Polytec. Several Polytec LSVs are integrated in the manufacturing process and provide the necessary readings for plant control.

Measure speed in production processes

Polytec LSVs are laser precision sensors which are used for a variety of velocity measurement processes in the steel, metal and aluminum industry:

- holding time determination in coating and surface treatment systems

- cutting device control/ synchronization in cutting-to-length applications

- drive and belt tension synchronization in roll stands

- cooling process monitoring, e.g. in laminar cooling mills

- skin-pass degree determination

- mass flow regulation in reversing and tandem mills.

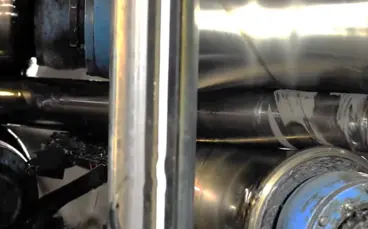

Rotary motion control

This is increasingly being used in tube rolling mills. The saw blade is moved around a circular course at the speed of the tube. The movements must be exactly synchronized, with speeds of up to 10 m/s. The Polytec LSV measures tube speed without slippage or wear as a means of controlling the rotary tube saw. As well as an exact vertical cut, using the LSV also makes it possible to achieve the smallest length tolerances.

Rotary tube saw control

Two Polytec LSVs are used in a stainless steel rolling mill to regulate a planetary cross-rolling mill. The simultaneous measurement of rotational and translational velocity at the outfeed of the rolling mill allows any hot steel rod rotation to be offset automatically.

Optical length and speed measurement in steel, aluminum and metals production

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters — get in touch with us today.