Reducing permanent load for increased lifetime

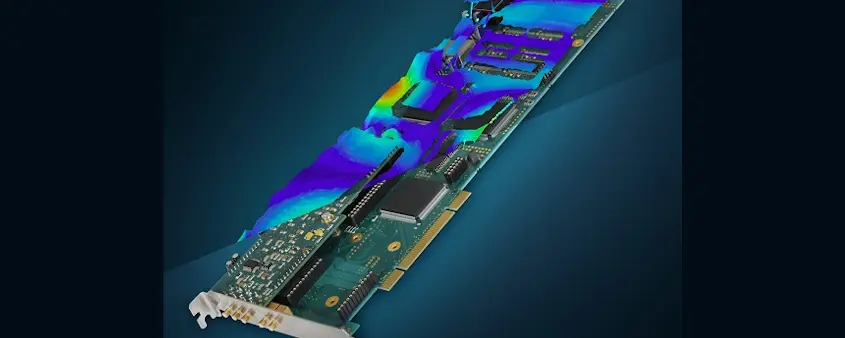

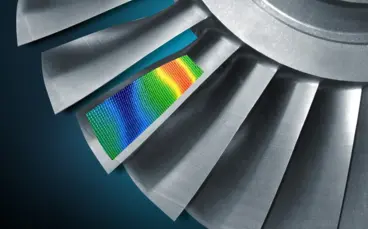

Failure is not an option – particularly in commercial aviation. In this industry, electronic components, printed circuit boards and sensors are exposed to continuous vibration loads. Testing printed circuit boards and structural elements in a way that simulates vibration and impact loads ensures continuous operating reliability. The non-contact vibration sensors from Polytec are ideal for dealing with this problem. The high-sensitivity laser technology reliably detects vibration-related weak points on printed circuit boards or individual components, right down to individual bond wires. Modal tests and order analyses quickly provide you with the right data for component, PCB, enclosure and attachment optimization.

Optical testing of electronics

Polytec Scanning Vibrometers allow you to take the printed circuit board’s vibration modes into consideration at the layout stage. This means that heavy components such as capacitors, or processors with cooling elements, can easily be positioned in the deflection shape nodes. Continuous loading can be reduced by 80% as a result of this and the service life can be increased accordingly. Visualization by Polytec is a critical resource for this.

Related products

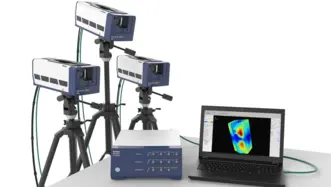

VibroScan QTec Xtra 3D

VibroScan QTec Xtra 3D measures vibrations triaxially in a new way - without contact, full-field and with unprecedented precision. With its groundbreaking multi-path interferometry, QTec® sets new standards in terms of optical sensitivity and interference immunity. The Xtra, based on an infrared (SWIR) laser is characterized by the highest optical sensitivity to guarantee highly accurate measurements even on demanding technical surfaces. VibroScan QTec Xtra 3D ensures maximum portability through integrated data acquisition and signal generator up to 32 MHz.

VibroScan QTec Xtra

VibroScan QTec Xtra measures vibrations in a new way - without contact, full-field and with unprecedented precision. With its groundbreaking multi-path interferometry, QTec® sets new standards in terms of optical sensitivity and interference immunity. The Xtra, based on an infrared (SWIR) laser is characterized by the highest optical sensitivity to guarantee highly accurate measurements even on demanding technical surfaces. VibroScan QTec Xtra ensures maximum portability through integrated data acquisition and signal generator up to 32 MHz.

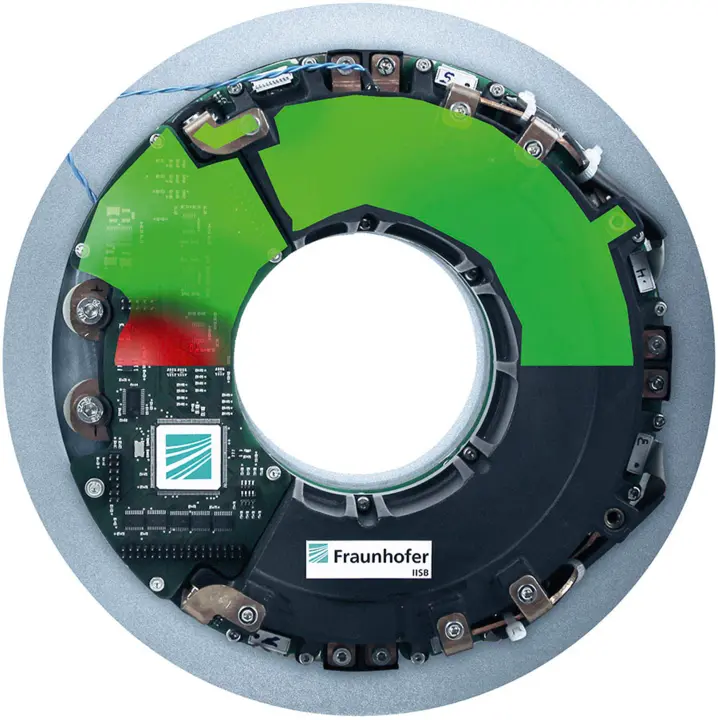

RoboVib®

By combining a 3D scanning vibrometer and an industrial robot, RoboVib® forms an automated test station for measuring everything from complex components to complete vehicle bodies. Reduce testing time and expenses as well as time to market significantly in experimental modal analysis. Conduct comprehensive 360° testing of a vehicle body, for example, within only one-two days and overnight instead of weeks of preparation with conventional test setups.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters—get in touch with us today.