Using powerful Xenon UV flash lamps

The market for printed circuitry is in a state of upheaval. Inks containing metallic nanoparticles enable printing on flexible, low-cost carrier substances such as paper and various plastic films. The challenge in sintering printed materials lies in maintaining a low heat input in the substrate at the same time. Polytec’s Xenon UV flash lamp systems provide the perfect solution to this problem.

Polytec offers various systems for R&D applications industrial in-line production.

As the European test centre for photonic sintering for the US partner company Xenon Corp., Polytec offers the technical prerequisites for testing photonic sintering.

R&D-Systems

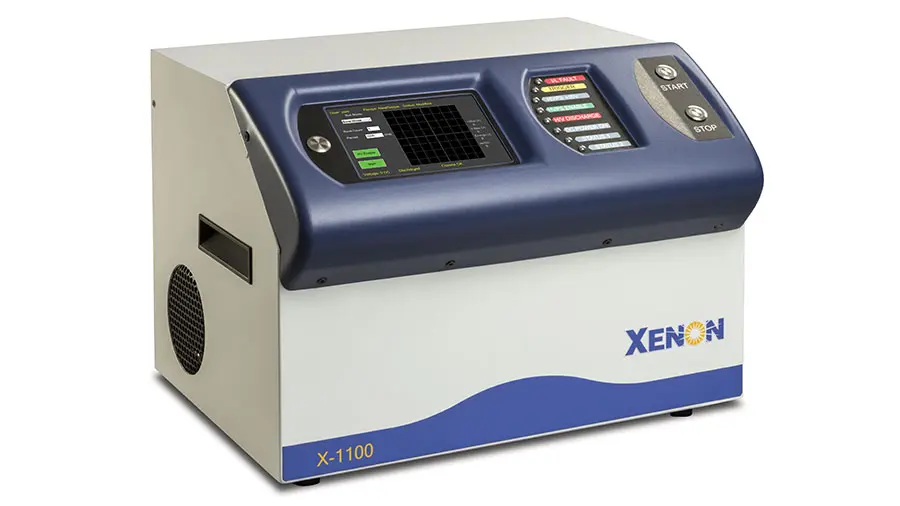

Flexible Desktop System for R&D requirements

The R&D system has been specially designed to meet research and development requirements. The precisely controlled pulse peak power, pulse duration and pulse energy permit the development of in-house methods for fast photonic curing. With a radiant power of up to 9 joules/cm2, the X-1100 is ideal for phototonic curing – also of complex layers.

Features

- Controllable pulse peak power, pulse duration and pulse energy

- Radiant power up to 9 Joule/cm2

- Control by intuitively operated touch screen

- Built-in oscilloscope for pulse measuring

- Complex energy delivery schemes can be defined

- Plug-in connections for different lamp housings and accessories

Sintering silver, copper and other printed materials

The Sinteron S-2100is a system for sintering silver, copper and other inks, curing thin-film substrates and treating surfaces in semiconductor and photovoltaic applications. The power supply units are housed in a 19″ rack. Power supply units and cooling form part of the system.

Pulse widths can be selected in the range between 100 and 2,000 microseconds. The pulse energy can be set between 27 and 2,000 joules/pulse.

The system can be varied with a multitude of lamps and thus adapted to the area to be processed. The optical effective area is, for instance, 19 × 305 mm for the 16″ linear lamp or around 140 mm in diameter for the spiral lamp.

Sintering silver & copper with a high pulse energy

The Sinteron S-2200 offers you state-of-the-art energy management. It meets all your needs when it comes to researching and developing new processes while processing printed nanomaterials and also to swift sintering on heat-sensitive substrates.

Features

- Configurable, high-frequency pulse sequences

- Single-pulse mode for high energies of up to 4 kW/cm²

- Graphical user interface and ease of use

- Simple synchronization with the linear table

The system can be combined with a multitude of lamps and thus adapted to the area to be processed. The optical effective area is, for instance, 19 × 305 mm for the 16” linear lamp or around 140 mm in diameter for the spiral lamp.

Large effective area & high homogeneity for R&D

XENON's S-2210 is a state-of-the-art flash lamp system for researchers and developers. It is used in the development of curing, drying and sintering processes. The excellent homogeneity of 3% over 150 x 150 mm allows for extensive use, e.g. on semiconductor wafers or PCBs. The compact design of the S-2210 makes it ideal for developing a process and then scaling for larger areas or higher throughput by integrating multiple identical racks.

Features

- Full flexibility in setting the pulse duration or energy

- Simple operation by touch screen interface, easy saving and retrieval of process parameters

- Ready for scaling the processes and thus for the transfer to production

- Maximum pulse energy delivery of 18 kJ

- Pulse width 100 μs to 5000 μs

- Voltage setting 2 to 3 kV

- Single Pulse, Burst, Sequence, Continuous

- Large effective optical area of 150 mm x 150 mm

- Homogeneity 3%

LS-845 Linear Table

The light of the linear lamp is screened from the user to ensure safe working. Suitable for working with sheets such as DIN A4 paper.

Chamber for spiral lamp

The optional LC-915 chamber allows you to work safely with the spiral lamp.

Industrial Systems

Sintering printed silver materials in the production process

The Sinteron S-5000 enables printed electronics to be processed on flexible substrates such as plastic films, fabrics and paper at a throughput of up to 30 meters per minute.

A maximum of ten lamps each measuring 49 cm in length can be separately controlled using a touch panel, as can the roll speed, footprints and overlaps as well as the pitch of the flash lamps.

A 16″ conveyor belt can be easily removed for integration in roll-to-roll systems.

Sinter materials on wide path substrates with ease

The Sinteron S-5100 is a big step forward for printed electronics. It enables you to sinter printed circuitry on wide path substrates in a roll-to-roll production environment.

Features

- Processing of path widths up to 125 cm

- Even energy distribution across the entire width

- Synchronization of pulses with the path speed to prevent stripes from forming

- Integrated touchscreen display for easy control of all parameters

- Air-cooled and thus no problems with water leaks and no additional use of toxic chemicals needed

Areal sintering with outstanding uniformity

The S-2210 is ideal for areal applications up to 150 x 150 mm effective area at high light intensity and outstanding uniformity of 3%. The system closes a gap in the Xenon sintering system series, which is now fully integrated from the X-1100 low cost device for benchtop R & D applications to the universal system S-2200. The versatile adjustable parameters enable the system to process nano-inks over pastes on heat-sensitive substrates up to photovoltaic thin-films.

Features

- Max. effective area: 150 x 150 mm

- Maximum pulse energy: 18 kJ / cm2

- Pulse duration: 100 - 5000 µs

- Light uniformity: 3 %

- Touch Screen operation

- Up to 40 individual pulse energies programmable

- 100 pulse profiles / pulse sequences programmable

- Modular extension for lager effective areas / higher throughput possible

Large-area UV curing and photonic sintering

The 60” linear lamp (1.5 m) is used for large-area UV curing and photonic sintering in in-line applications in roll-to-roll processes. Two single lamps with an elliptical reflector are combined such that the light is emitted over a large range with excellent homogeneity.