Process-Integrated Thickness Measurement

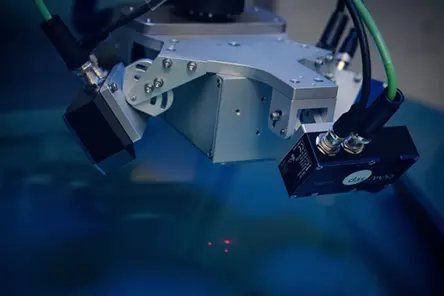

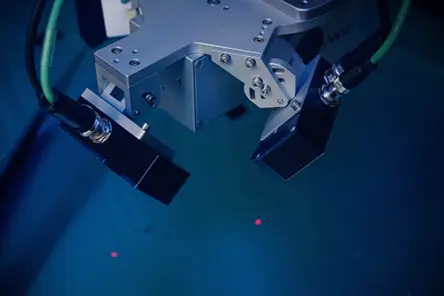

Terahertz systems enable contactless and non-destructive measurements in real time. They penetrate deeply into materials without damaging them, providing precise data on layer thickness, material homogeneity, or hidden defects.

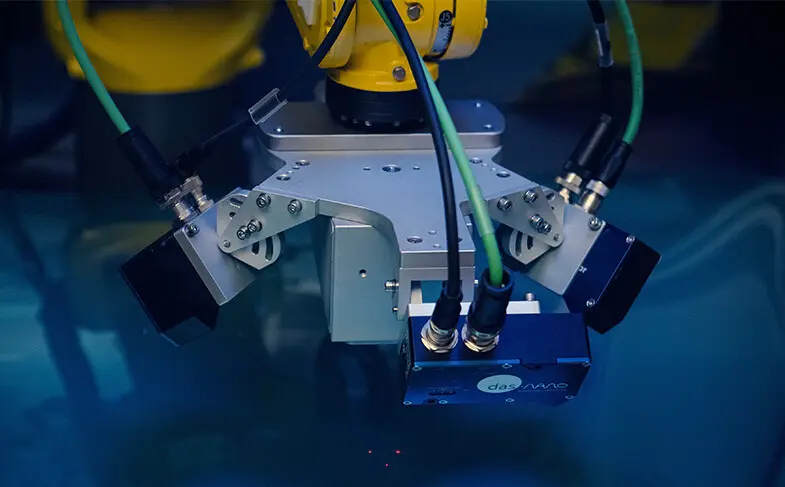

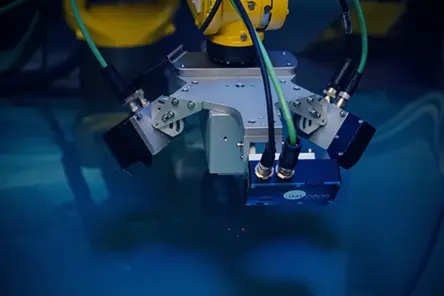

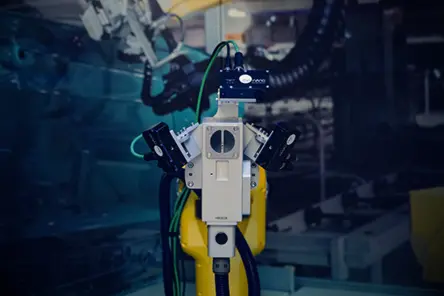

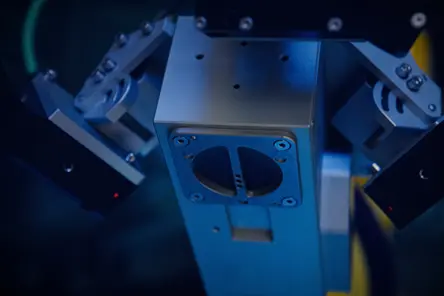

The Irys system from das-Nano was developed for non‐contact thickness measurement. Its main application is in quality control for automotive body painting. It enables measurements with accuracy down to one micrometer for up to five different layers.

Features

//- Completely contactless and non-destructive

- Real-time multilayer analysis

- Substrate-independent — works with different materials and material states

- Easy integration into automated processes

- Extremely fast and highly precise

- very versatile

- Intuitive software and automated reporting

- Safe for users due to non-ionizing radiation

Efficient, Non-Destructive Layer Measurement for Automated Automotive Painting

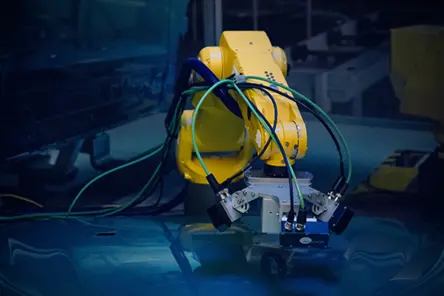

To ensure efficiency and precision in automotive painting, advanced non-destructive technologies are needed that allow material-independent measurements of layer structure for reliable quality control. Irys terahertz measurement systems fully meet these requirements and furthermore integrate seamlessly into automated, robot-assisted processes.

Outstanding Flexibility

Because it’s designed for seamless process integration, compatibility with standard robots and existing quality assurance systems was also a priority. A triangulation system with three lasers ensures precise orthogonal alignment of the measurement head, even for curved surfaces.

The system supports cable runs of up to 30 meters, providing high flexibility in installation — with maximum performance and no compromise in signal integrity.

An optional second sensor head increases efficiency and allows simultaneous measurements with two robots controlled by a single controller — ideal for applications where maximum throughput matters.

The IP54 protection rating ensures dust and water resistance, suitable for demanding industrial environments.

The system works for dry, wet, as well as cured coating states, allowing adaptation to different stages of the production process. Moreover, it operates on metals, composites, and plastics without requiring re-calibration.

Robust, 24/7 Proven Technology

The widespread use of Irys by leading OEMs speaks for itself and reflects the reliability and performance of the system in a variety of production environments.