Measuring transparent and non-transparent coatings under industrial conditions

Non-contact

The laser-based thickness measurement system Enovasense measures the opaque, semi-transparent or transparent coating without any contact with the object. Using lasers and IR sensors, it measures at working distances from 5 to 20 cm—even on conveyor belts, in high temperatures, or when the coating is wet or brittle.

Non-destructive

“Non-destructive” means completely tactilely non-invasive. The excitation laser causes only minimal heating, so neither the object nor the coating is affected or damaged during measurement.

Fast

The measurement itself takes less than one second. The Enovasense process is based on a physical model which enables pre-calibration of the system depending on the application. Calibration is both faster and easier compared to conventional methods. For some applications calibration can even be omitted entirely.

Compact

The measurement head has small dimensions (75 × 32 × 41 mm, weighing 150 g), enabling measurements in locations which were previously completely inaccessible.

Features

//- Contactless and non-destructive measurement

- Compact measurement head

- approx. 86 × 41 × 32 mm, weight ~180 g

- Measurable coating thicknesses

- 0.1 - 1000 µm

- Accuracy

- < 3% of the measured thickness

- Measurement time

- < 1 second

- Working distance:

- 20 - 150 mm

Automatic 3-Axis Measurement Station for Coating Thickness

Application-Specific Configurations

- Used for measuring medium-sized parts in process or in the lab

- Manually loaded, automated scanning

- Multiple operator-configurable measurement positions

- Large working area for manual part positioning with 3-axis 3D scanning

- Touchscreen for displaying measurements

- Automated sliding safety door

- Easy saving of measurement results (with part or batch number reference)

- Simple export of measurement data (CSV, TXT or others)

- Meets IEC60825 Class 1 safety specifications for lasers

- Special laser-safe window for observing the measuring sequence

- Inline system for epoxy and polyester paints on metallic, polymer and composite substrates and for enamel coatings

- Capable of measuring immediately after paint application as well as after curing or drying

- The measurement head includes a camera for object detection, a laser for targeting automatically generated measurement points, and a venting device

- Able to measure at varying speeds of the paint line and on different objects

- Multiple measurement heads can be combined when measurement from different sides is required

Accessories and components

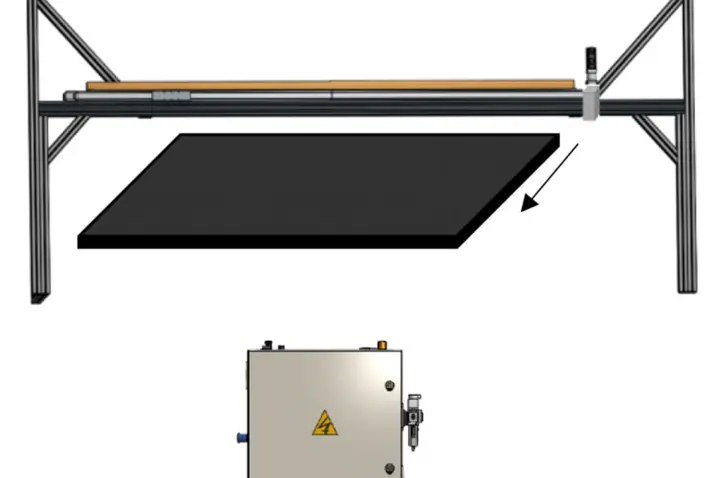

This movable linear traverse allows horizontally moving parts to be measured at a defined speed. This enables defined points along the produced parts to be measured and ensures 100% tracking in the process. The cross-travel axis makes it possible to measure at different width positions.

The conveyor belt integration consists of a frame, a protective housing for the measuring head, an automated axis for moving the head, a recalibration and protection box, and a control cabinet. The axis, measuring head, and its protection are mounted on the frame. The recalibration and protection box is located at the zero position of the axis. The control cabinet is positioned on one side of the line, connected to the measuring head, and transmits the data to the external system.

- Fully automated design

- Special protection for the measuring head and controller against harsh environmental conditions

- Regular automated calibration check at zero position in the head protection housing

- Dust-sealed and temperature-controlled cabinet for controller and axis drive

- Simple interface and measurement display

- Easy saving of measurements (with part or batch number reference)

- Easy export of measurement data (CSV, TXT formats or others)

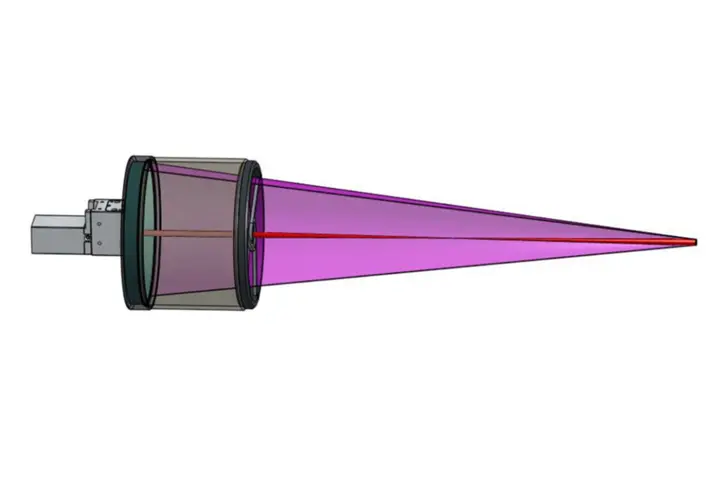

This module was developed to enable measurements with a wider distance between sensor and object as well as improved tolerance in positioning.

- Increased measuring distance

- Easily attachable to the standard measuring head

- Lightweight and durable aluminum construction

The distance objective is screwed directly onto the measuring head, replacing the standard lens. No special tools are required, and it can remain permanently mounted on the measuring head. The optimal working distance is 450 mm.

Related Articles

Photothermal measurement method for opaque coatings and all common substrates

For many industrial products, the quality of coatings plays an important role. For example, the material thickness, color, gloss, or adhesion of one or more layers on a substrate

Inline measurement system for powder coatings

Powder coating quality depends on thickness and uniformity, especially at critical points. Photothermal measurement systems offer practical solutions for quality control.

Precise layer thickness measurement without referencing

For many products, coating quality is crucial—such as material thickness, color, gloss, or adhesion of one or more layers to a substrate. Regardless of their purpose, measuring the thickness or uniformity …