Compact UV LED spot curing system for consistent, repeatable curing processes

The OmniCure LX500 spot curing system is based on UV LED technology and Intelli-Lamp® technology, which monitors the temperature and service life of the LED and controls the optical stability to within

+/- 5%. This achieves outstanding process reliability. The LX500 is available with two or four channels and is the most flexible and efficient system for industrial production.

The system controller offers a robust and intuitive user interface. Up to four LED heads can be controlled simultaneously and independently at different wavelengths: 365 nm, 385 nm and 400 nm. For long-term stability of the light source, new LED heads can be calibrated to tight tolerances to ensure a repeatable curing process and precise control of UV irradiation. The LX500 features StepCure® 2.0, which allows the user to programme different profiles within a single or multiple LED heads via each channel.

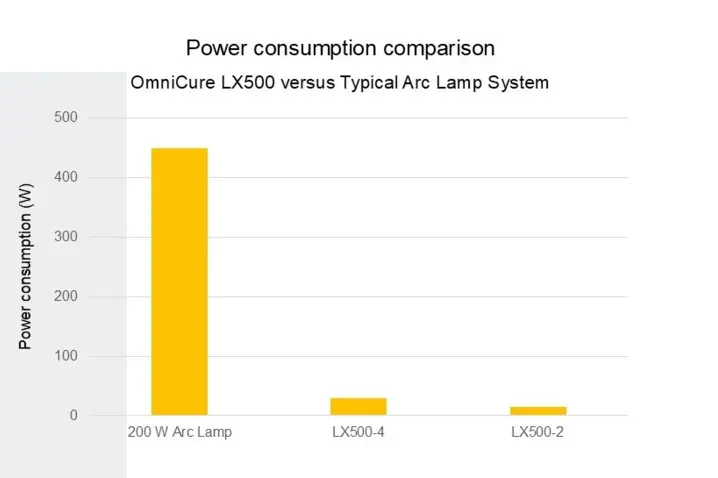

Power consumption comparison

High energy efficiency thanks to the use of the latest LED technology.

Features and specifications of OmniCure LX500

| Functions | Advantages |

|---|---|

| Latest UV LED technology for maximum irradiance at different wavelengths | Reduction in manufacturing costs for UV mounting with faster curing time and higher energy efficiency while supporting many UV-cured adhesives

|

| Precise control of the UV light source; exposure time (+/- 0.1 s) intensity level (+/- 1%) of up to four UV LED heads | Consistent repeat accuracy for maximum product quality |

| Intelli-Lamp LED technology | Stability of UV radiation for maximum energy efficiency and reliability over the entire LED service life |

| Control up to four UV LED spot curing heads simultaneously or independently with a single controller | Flexibility in production set-up |

| Micro SD card interface | Simple programming of single or multiple controllers in a single step. Saves exposure events and errors automatically |

| LED head temperature in the display | Optimum efficiency in UV-curing production processes and extension of the service life of the UV LED head |

| StepCure | Customised, multiphase curing processes that are programmed directly from the controller or via the PC interface |

| High energy efficiency thanks to the use of the latest LED technology | Approx. 75% less energy consumption than a typical UV arc curing system |

| Compact and robust system design | Maximum performance in confined and harsh production environments; no additional cooling required |

| User-friendly controls on the front panel | Simple operation for quick set-up in just a few minutes |

| CE and RoHS certification | Compliance with all requirements and safety standards |

| Technical data | |

|---|---|

| UV LED heads | 1 to 4 individual and interchangeable heads with each channel |

| 2.4 inch colour display | Main control, input configurations, system maintenance, LED information, calibration, micro SD protocol information |

| Set operating mode | 4-way membrane button control for system display and programming |

| Timer | Down-counting mode: Range adjustable from 999.9 s to 0.1 s, increment 0.1 s. Count-up mode: Timing controlled by the operator via the control panel on the front or foot pedals. |

| Intensity levels | 5% - 100% (increment 1%) |

| Start/Stop | Control: Start or stop the LED emission |

| Main switch ON/OFF | Separate on/off control |

| Error messages | In the event of an error or failure, an alarm symbol appears on the screen |

| Dimensions of the control unit | (H) 5.5 inch, (W) 3.5 inch, (D) 5.5 inch |

| External control description | Via optional foot pedal, PLC or PC via USB communication |

| Operating conditions/operating voltage | Power supply for the control unit 12V DC, input to AC adapter: 100 - 120 V AC or 200 - 240 V AC (+/- 10%) and 50/60 Hz |

| Rated power | 72 W max. at 120 V AC voltage 104 W max. at 240 V AC voltage (with 4 UV LED heads in operation) |

| Ambient temperature/humidity range | 5°C to 35°C, 85% max. (non-condensing) |

| Storage temperature/humidity range | -10°C to 60 °C, 85% max. (non-condensing) |

| Authorisations and safety standard | Fulfils RoHS and CE requirements |

| Guarantee | 1 year |