Large area UV curing systems for adhesives, coatings and inks

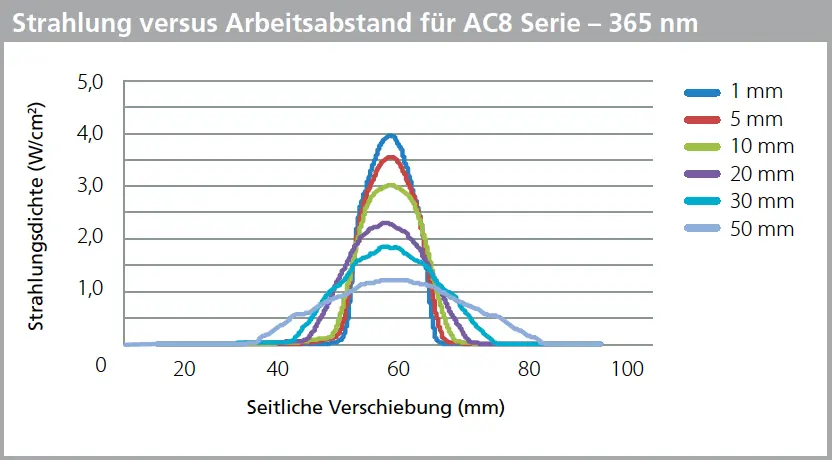

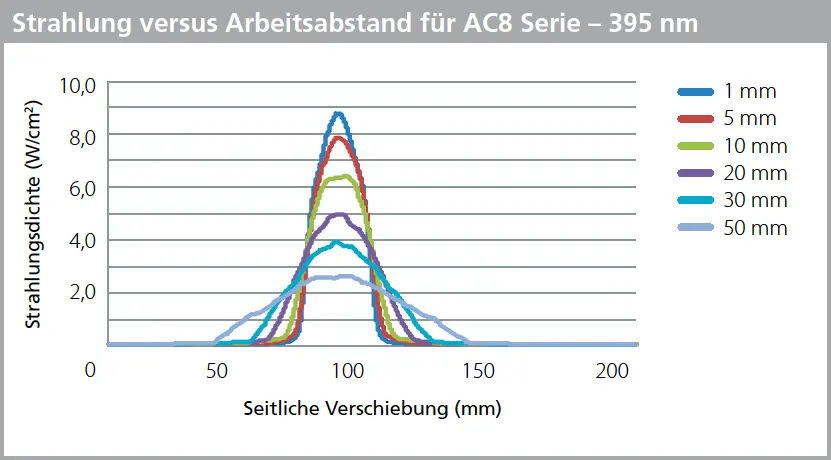

The OmniCure® AC8150/AC8150P, AC8225/AC8225P and AC8300 air-cooled UV LED curing systems are designed with state-of-the-art, customized front-end optics for powerful, high peak radiation. The systems deliver over 8 W/cm2 peak radiation for fast, uniform curing at long working distances. “P” versions of the AC8 series (AC8150P and AC8225P) have extended optics to optimize dose for short working distances required for printing applications. By customizing performance to meet the needs of the industry, the new AC8 Series product range can be used in a wide variety of applications with different process requirements.

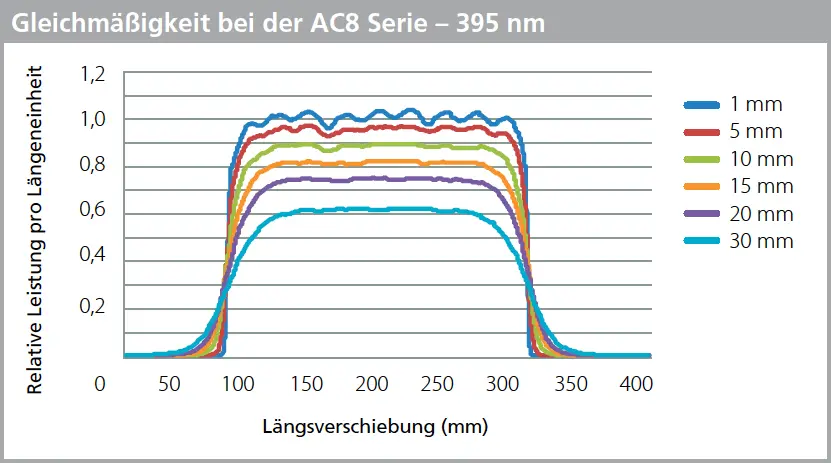

With a robust architecture, the OmniCure AC8 series is compact in design and allows different UV LED heads to be mounted without compromising optical uniformity in different systems. The flexibility to achieve greater curing ranges in various customizable lengths allows manufacturers to increase throughput while maintaining maximum output. By utilizing our patented process for individual UV LED module outputs, the AC8150/P, AC8225/P and AC8300 devices deliver exceptional uniformity across the entire curing range, improving productivity and reducing operating costs for manufacturers.

Features and specifications

| Feature | Advantages |

|---|---|

| Power output greater than 8W/cm2 | Fast curing for adhesives and coatings |

| Customizable front-end optics | Powerful, high peak radiation and exceptional uniformity at different working distances |

| Patented process for customizable LED module outputs | Greater uniformity across the entire curing range |

| Connect multiple systems with +/- 10% uniformity between heads | Uniform and consistent curing across curing zones of any size |

| Available in 395 nm and 365 nm | Ability to select the optimal wavelength for the adhesive, coating, or ink, as well as the substrate that best suits the specific application |

| Air-cooled | Easy to integrate into any workstation without the need for additional ventilation, ozone extraction, or cooling equipment |

| Highly efficient LED modules | Cost savings through reduced power consumption compared to arc lamp systems |

| Compact size | Easy to integrate into new or existing production lines |

| 20,000 hours typical lifetime | Reduced operating costs compared to solutions with arc lamps |

| Advanced optics specifically for printing applications (“P” versions) | Power adjustment to meet the process requirements of the printing industry for maximum performance |

| Narrow output wavelength for the LED | Higher yield of parts due to low-temperature curing compared to arc systems |

| Technical data | AC8150 | AC8225 | AC8300 | |||

|---|---|---|---|---|---|---|

| LED peak wavelengths | 365 nm ± 5 nm, 395 nm ± 5 nm | |||||

| Active optical range | 152 x 15 mm | 225 x 25 mm | 300 x 25 mm | |||

| Power consumption | 956 W | 1430 W | 1904 W | |||

| Dimensions (L x W x H) | 159 x 80 x 218 mm | 235 x 80 x 218 mm | 311 x 80 x 218 mm | |||

| Typical peak radiation (W/cm2): | 365 nm | 395 nm | 365 nm | 395 nm | 365 nm | 395 nm |

| Working distance 1 mm | 4,0 | 8,5 | 4,0 | 8,5 | 4,0 | 8,5 |

| Working distance 10 mm | 3,0 | 6,2 | 3,0 | 6,2 | 3,0 | 6,2 |

| Working distance 20 mm | 2,3 | 4,5 | 2,3 | 4,5 | 2,3 | 4,5 |

| Working distance 30 mm | 1,9 | 3,8 | 1,9 | 3,8 | 1,9 | 3,8 |

| Working distance 40 mm | 1,5 | 3,0 | 1,5 | 3,0 | 1,5 | 3,0 |

| Working distance 50 mm | 1,2 | 2,5 | 1,2 | 2,5 | 1,2 | 2,5 |

| Optical power | 133 W | 273 W | 200 W | 400 W | 267 W | 400 W |

| Weight (kg) | 3,6 | 2,5 | 4,4 | 2,7 | 5,2 | 2,9 |

| Longitudinal uniformity | Better than ± 10% | |||||

| Operating voltage | 48 V GS ± 2 V | |||||

| Cooling | Air | |||||

| Life expectancy | >20,000 hours | |||||

| Automation | Integrated PLC controls for UV intensity and system alarms | |||||

| LED warranty | 2 years or 10,000 operating hours | |||||

| Adhesive brand | Model | Curing with 395 nm | Curing with 365 nm | Curing speed AC5 series | Curing speed AC5 series |

|---|---|---|---|---|---|

| DuPont | 2420 | good | good | 4-6 cm/s | 8-10 feet/min |

| DuPont | 2220 | good | good | 7-8 cm/s | 14-16 feet/min |

| DuPont | 2110 | good | good | 4-5 cm/s | 8-10 feet/min |

| 3M | 1796 | good | good | 4-5 cm/s | 8-10 feet/min |

| 3M | 2003 | good | good | 4-5 cm/s | 8-10 feet/min |

| 3M | MG250-55 | good | good | 7-8 cm/s | 14-16 feet/min |

| Loctite | 3972 | good | good | 4-5 cm/s | 8-10 feet/min |

| Loctite | 3971 | good | good | 4-5 cm/s | 8-10 feet/min |

| Loctite | 3321 | good | good | 4-5 cm/s | 8-10 feet/min |

| Loctite | 3311 | good | good | 4-5 cm/s | 8-10 feet/min |

| Loctite | 3105 | good | good | 7-8 cm/s | 14-16 feet/min |

| Loctite | 3106 | good | good | 7-8 cm/s | 14-16 feet/min |

| Loctite | 3555 | good | good | 7-8 cm/s | 14-16 feet/min |

| Loctite | 352 | good | good | not available | not available |

| DELO | 496 | good | good | 5-6 cm/s | 10-12 feet/min |

| DELO | 486 | good | good | 4-5 cm/s | 8-10 feet/min |

| Dymax | 3094 | good | good | 2-3 cm/s | 4-6 feet/min |

| Dymax | 1187 | good | good | 4-5 cm/s | 8-10 feet/min |

| Dymax | 204 CTH | good | good | 7-8 cm/s | 14-16 feet/min |

| Dymax | 206 CTH | good | good | 7-8 cm/s | 14-16 feet/min |

| Dymax | 191-M | good | good | 7-8 cm/s | 14-16 feet/min |

| Dymax | 1181-M | good | good | 7-8 cm/s | 14-16 feet/min |

| ThreeBond | 3013 | good | good | 2-3 cm/s | 4-6 feet/min |

| ThreeBond | 3033 | not applicable | good | not available | not available |

| ThreeBond | 3052 | not applicable | good | not available | not available |

| Norland | 121 | good | good | 2-3 cm/s | 4-6 feet/min |

| Norland | 61 | not applicable | good | not available | not available |

| Parlite | 4019 | good | good | 2-3 cm/s | 8-10 feet/min |

| Parlite | 4025 | good | good | 2-3 cm/s | 8-10 feet/min |

| Sony Chemical | SVR1120 | not applicable | good | not available | not available |

| Sony Chemical | SVR3030 | not applicable | good | not available | not available |

| Emerson & Cuming | UV9060 | good | good | 7-8 cm/s | 14-16 feet/min |

Applications

The AC8150/AC8150P, AC8225/AC8225P, and AC8300 systems are ideal for a wide range of medical devices, electronic and optoelectronic systems, and printing applications, such as:

Medicine

- Anesthesia masks

- Blood bags

- Catheters

- Contact lenses

- Endoscopes

- Filter sets

- Insulin pens

- Syringes

- Tube sets

Electronics

- Camera modules

- Chip-on-glass

- Connectors

- Display bonding

- Wafer tape removal

- Flexible circuit assemblies

- Hard disk drives

- Lens bonding

- Micro speakers

Printing

The high radiation power and uniformity of the AC450 and AC475 are ideal for UV printing applications such as:

- Coding

- Labels

- Product marking

- Serial numbers

- Posters and signage

- Packaging

- 3D printing