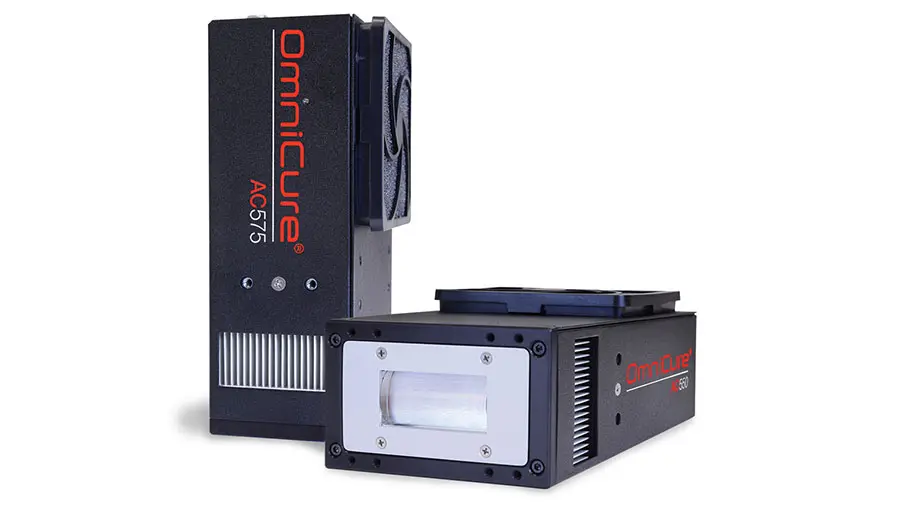

High-performance, small-area UV LED curing systems for adhesives, coatings, and inks

OmniCure®'s AC550, AC550P, AC575, and AC575P air-cooled UV LED curing systems feature state-of-the-art end optics to deliver powerful high peak irradiance and exceptional uniformity at varying working distances. The systems deliver 14W/cm2 peak irradiance for fast, uniform curing, even at long working distances. The P versions of the AC5 series feature improved optics for dose optimization at short working distances and a removable window for easy cleaning in printing applications.

The OmniCure AC5 series uses a patented process to address individual UV LED module outputs for exceptional uniformity across the entire curing area. A consistent exposure area allows larger and/or multiple parts to be cured simultaneously. Furthermore, the AC5 series offers the possibility of transforming a static curing process into a dynamic one, in which parts can cure while in motion, thereby increasing throughput.

Features and specifications

| Feature | Advantages |

|---|---|

| Output power 14 W/cm2 | Faster curing speed for adhesives, coatings, and inks. |

| Available in standard pressure versions at 395 nm | Adaptation to support process requirements, such as general bonding, conformal coating, and printing. |

| Customized optics | Greater flexibility in the curing process thanks to higher peak irradiance at greater working distances. The pressure (P) versions feature improved optics for dose optimization at short working distances and a removable window for easy cleaning. |

| Patented method for addressing individual LED modules | Uniform and consistent curing thanks to excellent uniformity across the entire LED area. |

| Air-cooled | Easy to integrate into any workstation. No additional ventilation, ozone extraction, or cooling required. |

| I/O connection for remote operation | Option of automation to increase productivity. |

| Highly efficient LED modules | Cost savings thanks to reduced energy consumption compared to arc lamp systems. |

| Compact dimensions | Easy to integrate into any workstation. |

| Typical service life of 20,000 hours | Reduced operating costs compared to arc lamp solutions. |

| Narrow wavelength output of the LED | Increased yield of parts compared to arc lamp systems due to lower curing temperatures. |

| Technical data | AC550/ AC550P | AC575/ AC575P | ||

|---|---|---|---|---|

| LED peak wavelengths | 385 nm ± 5 nm | |||

| Active optical range | 50 x 25 mm | 75 x 25 mm | ||

| Power consumption | 330 W | 480 W | ||

| Optical power | 123 W | 184 W | ||

| Typical peak radiation (W/cm2): | 395 nm | |||

| Working distance 1 mm | 14,0 | |||

| Working distance 5 mm | 12,6 | |||

| Working distance 10 mm | 10,6 | |||

| Working distance 15 mm | 9,0 | |||

| Working distance 20 mm | 7,7 | |||

| Working distance 25 mm | 6,7 | |||

| Noise level | < 65 dB | |||

| Weight (kg) | 1,1 kg | |||

| Longitudinal uniformity | Better than ± 10% | |||

| Operating voltage | 48 V DC ± 2 V | |||

| Cooling | Air | |||

| Dimensions (L x W x H) | 110 x 68 x 190 mm | |||

| Life expectancy | > 20,000 hours | |||

| Automation | Integrated PLC for UV control | |||

| LED warranty | 2 years or 10,000 operating hours | |||

| Adhesive brand | Model | Curing with 395 nm | AC5 series curing speed | AC5 series curing speed |

| DuPont | 2420 | good | 50-70 mm/s | 11-12 feet/min |

| DuPont | 2220 | good | 90-110 mm/s | 19-21 feet/min |

| DuPont | 2110 | good | 50-70 mm/s | 11-13 feet/min |

| 3M | 1796 | good | 50-70 mm/s | 11-13 feet/min |

| 3M | 2003 | good | 50-70 mm/s | 11-13 feet/min |

| 3M | MG250-55 | good | 90-110 mm/s | 19-21 feet/min |

| Loctite | 3972 | good | 50-70 mm/s | 11-13 feet/min |

| Loctite | 3971 | good | 50-70 mm/s | 11-13 feet/min |

| Loctite | 3321 | good | 50-70 mm/s | 11-13 feet/min |

| Loctite | 3311 | good | 50-70 mm/s | 11-13 feet/min |

| Loctite | 3105 | good | 90-110 mm/s | 19-21 feet/min |

| Loctite | 3106 | good | 90-110 mm/s | 19-21 feet/min |

| Loctite | 3555 | good | 90-110 mm/s | 19-21 feet/min |

| Loctite | 352 | no | N/A | N/A |

| DELO | 496 | good | 70-80 mm/s | 13-16 feet/min |

| DELO | 486 | good | 50-70 mm/s | 11-13 feet/min |

| Dymax | 3094 | good | 30-40 mm/s | 5-8 feet/min |

| Dymax | 1187 | good | 50-70 mm/s | 11-13 feet/min |

| Dymax | 204 CTH | good | 90-110 mm/s | 19-21 feet/min |

| Dymax | 206 CTH | good | 90-110 mm/s | 19-21 feet/min |

| Dymax | 191-M | good | 90-110 mm/s | 19-21 feet/min |

| Dymax | 1181-M | good | 90-110 mm/s | 19-21 feet/min |

| ThreeBond | 3013 | good | 30-40 mm/s | 5-8 feet/min |

| ThreeBond | 3033 | no | N/A | N/A |

| ThreeBond | 3052 | no | N/A | N/A |

| Norland | 121 | good | 20-30 mm/s | 4-6 feet/min |

| Norland | 61 | no | N/A | N/A |

| Parlite | 4019 | good | 50-70 mm/s | 11-13 feet/min |

| Parlite | 4025 | good | 50-70 mm/s | 11-13 feet/min |

| Sony Chemical | SVR1120 | no | N/A | N/A |

| Sony Chemical | SVR3030 | no | N/A | N/A |

| Emerson & Cuming | UV9060 | good | 90-110 mm/s | 19-21 feet/min |

Applications

Medicine

The AC550/P and AC575/P systems are ideal for many applications in the manufacture of medical devices that require high throughput and low temperatures during curing, such as:

- Anesthesia masks

- Blood bags

- Catheters

- Contact lenses

- Endoscopes

- Filter sets

- Insulin pens

- Syringes

- Tube sets

Electronics

The AC550 and AC575 systems are ideal for many applications in electronic assembly manufacturing that require high throughput and low temperatures during curing, such as:

- Camera modules

- Chip-on-glass

- Connectors

- Display bonding

- Flexible circuit assemblies

- Hard disk drives

- Lens bonding

- Micro speakers

Printing

The high irradiation power and homogeneity of the AC550P and AC575P are ideal for UV printing applications such as:

- Coding

- Labels

- Product marking

- Serial numbers