Cure small areas of adhesives, coatings, and paints

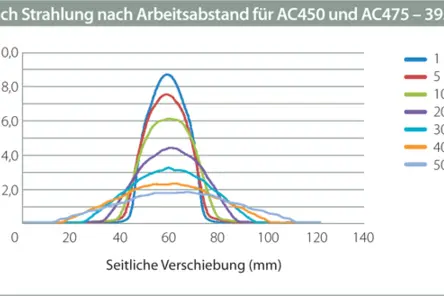

Manufactured with a unique combination of high-performance LEDs and customizable optics, the air-cooled OmniCure® AC450 and AC475 UV LED lamp systemsoffer high irradiance (>8W/cm2) with flexible operating distances, enabling manufacturers to achieve excellent productivity at low operating costs.

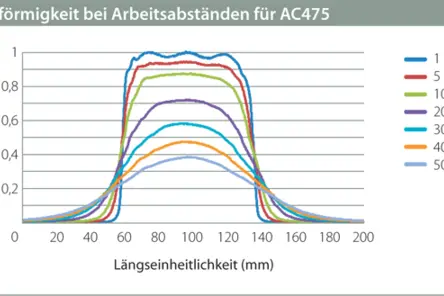

Using Excelitas' patented processes for addressing individual UV LED module power, the AC450 and AC475 LED curing systems deliver consistent results by providing high longitudinal uniformity across the entire curing range from 50 mm to 75 mm. A uniform exposure area allows larger and/or multiple parts to be cured simultaneously. To increase throughput, it is also possible to convert a static curing process into one where parts are cured while in motion.

Features and specifications

| Feature | Advantages |

|---|---|

| Output power 8 W/cm2 | High-speed curing for adhesives, coatings, and inks |

| Customizable front-end optics | Greater flexibility in the curing process thanks to maximum irradiation intensities at greater operating distances |

| Patented process for controlling specific LED modules | Uniform and consistent curing thanks to excellent regularity across the entire LED range |

| Connect multiple systems with +/- 10% uniformity between heads | Option to select the optimum wavelength for the adhesive, coating, or ink, as well as the substrates, individually tailored to each application |

| Available in 395 nm and 365 nm | Easy to integrate into any workplace, no additional ventilation, ozone filtering, or cooling required |

| I/O port for remote control | Automation option to increase productivity |

| Highly efficient LED modules | Saves energy costs compared to conventional arc lamps |

| Compact size | Easy to integrate into any workplace |

| 20,000 hours service life | Lower operating costs compared to conventional arc lamps |

| Narrow wavelength output via LED | Higher parts yield due to lower temperatures during UV curing compared to conventional arc lamps |

| Technical data | AC450 | AC475 | ||

|---|---|---|---|---|

| LED peak wavelengths | 365 nm ± 5 nm, 395 nm ± 5 nm | |||

| Active optical range | 50 x 25 mm | 75 x 25 mm | ||

| Dimensions (L x W x H) | 110 x 68 x 190 mm (L x B x H) | |||

| Typical peak radiation (W/cm2): | 365 nm | 395 nm | 365 nm | 395 nm |

| Working distance 1 mm | 4,0 | 8,0 | 4,0 | 8,0 |

| Working distance 10 mm | 2,8 | 5,7 | 2,8 | 5,7 |

| Working distance 20 mm | 1,9 | 3,7 | 1,9 | 3,7 |

| Working distance 30 mm | 1,5 | 2,8 | 1,5 | 2,8 |

| Working distance 40 mm | 1,2 | 2,0 | 1,2 | 2,0 |

| Working distance 50 mm | 1,0 | 1,7 | 1,0 | 1,7 |

| Optical power | 45 W | 90 W | 68 W | 135 W |

| Weight (kg) | 1,1 kg | |||

| Longitudinal uniformity | Better than ± 10% | |||

| Operating voltage | 48 V GS ± 2 V | |||

| Cooling | Air | |||

| Acoustic noises | < 65 dBA, load-dependent | |||

| Life expectancy | >20,000 hours | |||

| Automation | Integrated PLC controls for UV intensity and system alarms | |||

| LED warranty | 1 year; 10,000 operating hours (alternator) | |||

Applications

Medicine

The AC450 and AC475 systems are ideal for the many different medical device assembly applications that require high throughput and low-temperature curing (e.g., for plastic parts). For example:

- Anesthesia masks

- Blood bags

- Catheters

- Contact lenses

- Endoscopes

- Filter sets

- Insulin pens

- Syringes

- Tube sets

Electronics

The AC450 and AC475 systems are ideal for the many different electronics assembly applications that require high throughput and low-temperature curing. For example:

- Camera modules

- Chip-on-glass

- Connectors

- Display connections

- Flexible printed circuits

- Hard disk drives

- Lens bonding

- Micro speakers

Printing

The high radiation output and uniformity of the AC450 and AC475 are ideal for UV printing applications.

For example:

- Coding

- Labels

- Product marking

- Serial numbers