Curing inks, coatings, and adhesives

TheOmniCure® AC275 and AC2110 air-cooled UV LED curing systems combine compact size with state-of-the-art collimation optics for high irradiance and excellent uniformity. Multiple UV LED heads can be connected together while maintaining optical homogeneity between each system. The flexibility to achieve larger curing zones in various customizable lengths allows manufacturers to increase throughput without compromising performance.

Standard AC2 systems have a significantly reduced beam divergence angle compared to typical LED systems, making them ideal for printing applications where they help prevent light reflection back onto the print heads. All AC2 products come with a flat exit window that allows for easy cleaning and replacement. The infinitely variable adjustment of the radiation power enables a wide range of applications for the new AC2 series.

Features and specifications

| Feature | Advantages |

|---|---|

| Compact size | Easy to integrate into applications and machines, especially where space is limited |

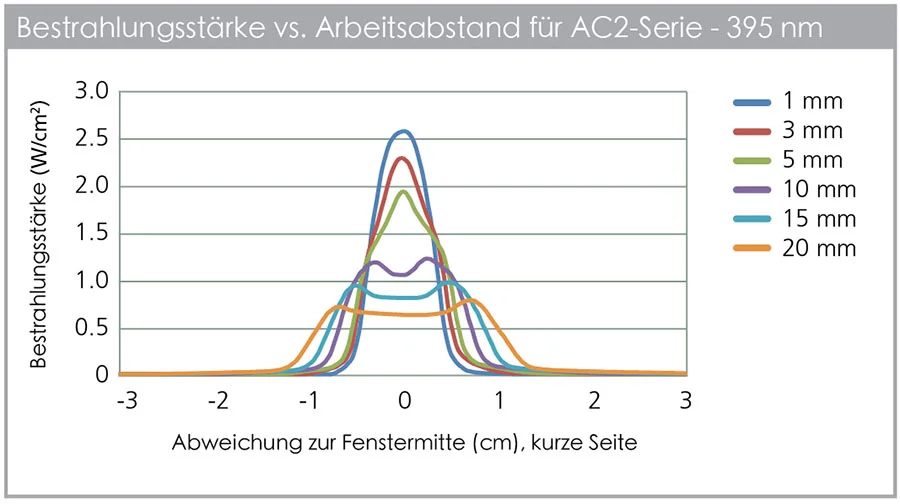

| Power output greater than 2.5 W/cm² | Fast curing of inks, adhesives, and coatings |

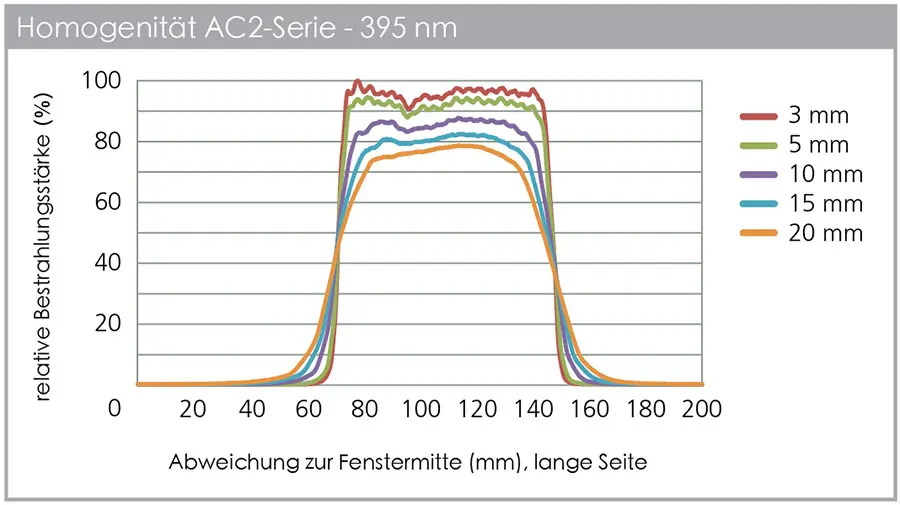

| Collimation optics | High irradiance and excellent irradiation homogeneity at a wide range of working distances |

| Advanced optics specifically for printing applications | Small beam angle to prevent light reflection in printing applications |

| Patented process for individual LED module outputs | Greater uniformity across the entire curing range |

| Combination of multiple systems with +/- 10% uniformity between individual AC2 heads | Uniform and consistent curing for any width |

| Available with 395 nm and 365 nm | Optimal wavelength for adhesives, coatings, inks, and substrates, depending on the application |

| Air cooling | Easy to integrate without the need for additional ventilation, ozone extraction, or cooling equipment |

| Highly efficient LED modules | Cost savings through reduced power consumption compared to conventional UV lamps (e.g., mercury lamps) |

| 20,000 hours typical lifetime | Significantly reduced operating costs compared to solutions with short-lived conventional UV lamps |

| Narrow-band LED wavelength range | Compared to conventional UV lamps, higher UV efficiency with significantly lower temperatures and lower energy input into the substrate |

| Technical data | AC275 | AC2110 | ||

|---|---|---|---|---|

| LED peak wavelengths | 395 nm ± 5 nm, 365 nm ± 5 nm | 395 nm ± 5 nm, 365 nm ± 5 nm | ||

| Active optical range | 10 x 75 nm | 10 x 114 nm | ||

| Dimensions (L x W x H) | 79 x 29 x 129 mm | 117 x 29 x 129 mm | ||

| Typical peak radiation (W/cm2) @ 395 nm: | ||||

| Working distance 1 mm | 2,6 | 2,6 | ||

| Working distance 3 mm | 2,3 | 2,3 | ||

| Working distance 5 mm | 1,9 | 1,9 | ||

| Working distance 10 mm | 1,2 | 1,2 | ||

| Working distance 15 mm | 1,0 | 1,0 | ||

| Working distance 20 mm | 0,8 | 0,8 | ||

| Optical power* | 13 W | 19 W | ||

| Weight (kg) | 0,3 | 0,44 | ||

| Longitudinal uniformity* | Better than ± 10% | |||

| Operating voltage | 48 V GS ± 2 V | |||

*at 100% output setting

Note: All measurements are taken using the EIT PowerPuck II radiometer with UVA2 filter.