Curing adhesives intelligently

The OmniCure® S2000 UV spot curing system provides the highest level of process control and consistency with real-time closed-loop feedback technology using an integrated optical UV sensor. When paired with an OmniCure® R2000 radiometer, the S2000 light curing system enables light output of unparalleled precision and delivers reproducible adhesive curing results.

When it comes to safety and consistent results in a production process, the OmniCure® S2000 is recognised as the world leader in UV spot curing systems for bonding precision assemblies using light-cured adhesives. With a powerful 200W UV lamp and the ability to automatically monitor operating hours through patented Intelli-Lamp® technology, the S2000, alongside its successor, the S2000 Elite, is the smartest light curing system in its class.

Specifications of OmniCure® S2000

| Technical data | |

|---|---|

| Service life of the UV curing lamp | 2,000 hours (guaranteed) |

| Available filters for the UV curing system | Standard: 320–500 nm Optional: 250–450 nm*, 365 nm, 320–390 nm, 400–500 nm |

| Control panel controls | Switch on/off, display mode, up/down setting, start/stop, lock/unlock |

| Control panel display | Totalised UV lamp usage, exposure time (0.2-999.9 sec.) iris setting (0-100)/ irradiance (0.2 W/cm²-4 W/cm²), lamp on, iris open, calibrated, light guide inserted, iris/key error, lamp warm-up |

| Warm-up time | 4 minutes (typical) |

| Input power | 100–120 VAC / 200–240 VAC, 50/60 Hz |

| Power supply | High efficiency, switching mode, line-insulated |

| Dimensions (L x W x H) | 13.3″ x 7.1″ x 7.9″ (33.8 cm x 18.0 cm x 20.1 cm) |

| Weight | 4.5 kg (9.9 lbs) |

| Scope of delivery of the light curing system | UV lamp module, selected filter (built-in), eye protection, earthed and shielded mains cable, foot pedal, operating instructions |

| Guarantee | 1 year (except UV lamp and light guide) |

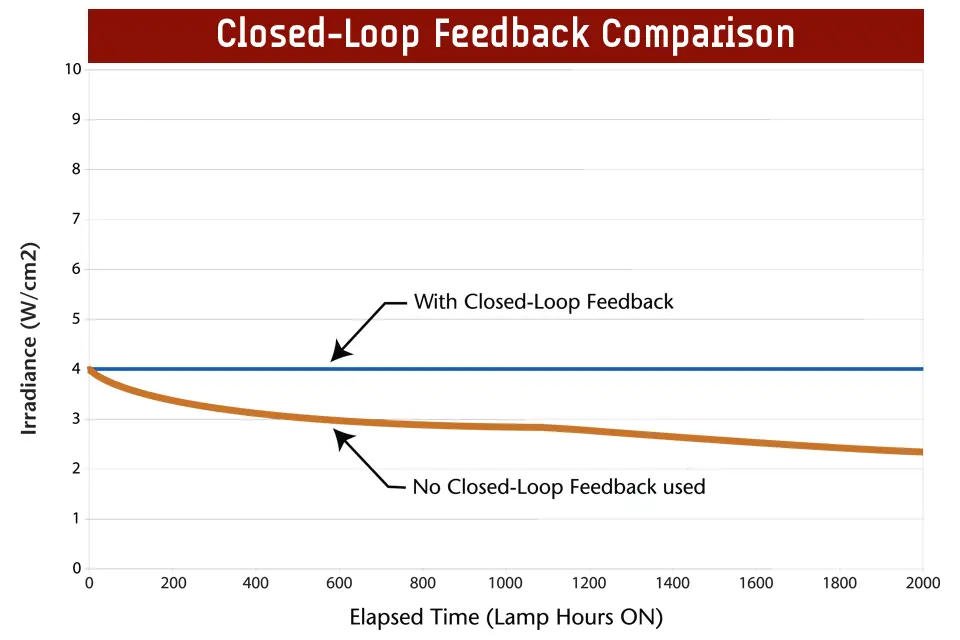

UV sensor with control loop feedback

Normally, the intensity of the UV lamp decreases over time, which affects the outcome and consistency of the UV curing process. To automatically compensate for this effect, the OmniCure® S2000 UV curing system is designed with an intelligent UV sensor control loop that constantly monitors light output in real time and makes simultaneous precise adjustments with a motorised iris to maintain consistent light output within +/-5% of the curing system set point. Proprietary closed-loop feedback technology ensures that a repeatable and measurable energy dose is delivered with each light exposure, resulting in increased production output and consistent quality.

Control loop feedback on the S2000 can be run in either relative power or absolute radiation mode. When the UV curing system is calibrated with an OmniCure® R2000 radiometer, the radiation mode is automatically activated, providing a real-time display of the curing system's output.

A PLC/audible alarm alerts operators when the UV lamp can no longer produce the set radiation intensity. Now any UV curing system lamp can be used consistently until the end of its life without the need to manually monitor the intensity of the UV lamp.

The only system that can be calibrated in real time for NIST accuracy.

- Ideal for automated and semi-automated environments

- Often imitated - never equalled

- Developed by Excelitas Technologies

Patented Intelli-Lamp® technology

At the centre of the OmniCure® S2000 UV curing system is the unique Intelli-Lamp® technology.

- UV lamp with guaranteed long service life

- The OmniCure® S2000 Intelli-Lamp® is guaranteed to ignite for at least 2,000 hours of operation with a maximum service life of up to 4,000 hours.

- Automatic tracking of UV lamp hours

- Each Intelli-Lamp® chip module automatically records and maintains UV lamp operating hours to facilitate lamp warranty activation when needed.

- Broad spectral output of the light curing system

- The Intelli-Lamp® delivers output across virtually the entire visible and UV spectrum, making it suitable for a wide range of adhesive/substrate bonding applications.

- Pre-aligned & focussed

- Snap-in insertion enables quick and easy Intelli-Lamp® installation while ensuring consistent alignment of the optical tube and UV sensor.

- Integrated Reflector

- Each Intelli-Lamp® includes an integrated reflector, eliminating the need for a separate replacement reflector in the UV curing system.

- Hot ignition prevention

- Automatic lamp temperature monitoring cools the UV curing system and protects against accidental hot ignition to further extend the life of the UV lamp.