Intelligent designing of thermography application

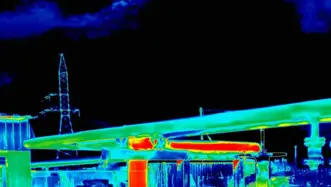

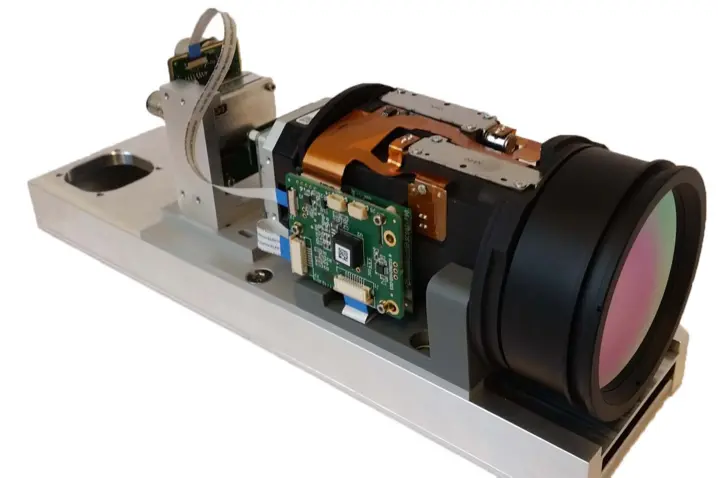

The IRSX thermography camera is the first intelligent, self-contained thermal imaging system that has been consistently developed for industrial use.

After the one-time setup, the system works as a stand-alone solution and communicates directly with process control. Ideal conditions for Industrie 4.0 applications.

As an all-in-one solution, it contains a calibrated thermal image sensorand a powerful processor with a variety of industrial interfaces in a compact, robust IP67 housing.

The IRSX camera can automatically switch between several inspection tasks and allows the flexible use of production lines with different products.

The camera is available in different versions with different resolutions, frame rates, zoom, microscope and wide angle lenses and as OEM version.

Reduce your system costs, because you no longer need extra computers, special software or external interfaces for your thermal imaging!

Highlights

//- Stand-alone thermal imaging

- easily integrated into industrial processes

- Integration without programming effort

- Web-based configuration and visualisation

- Consistently suitable for industrial use due to robust design

- IP67 protection class and industry-standard protocols and interfaces

- Apps available for numerous applications

Turnkey solutions

In addition to various applications such as the monitoring of substations, flame and flare systems or the inspection of electronic components, we offer turnkey solutions for the following applications:

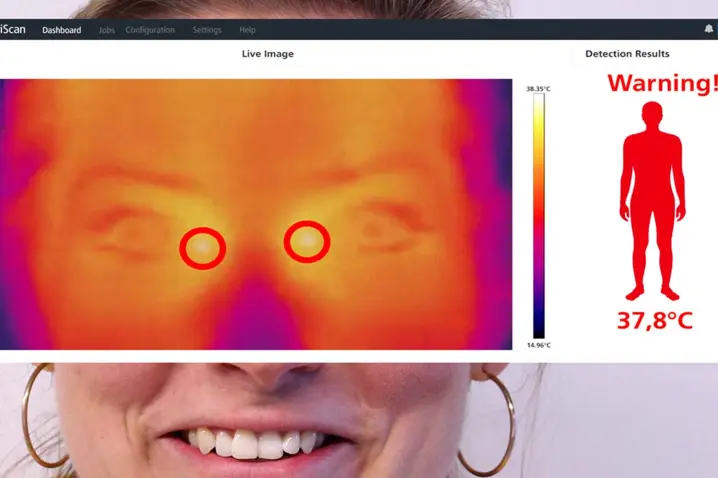

TI FeverScan is a solution for the detection of possible fever patients (e.g. corona-infected) based on high-precision temperature image evaluation (0.1°C accuracy). The access monitoring system with contactless temperature measurement can be quickly installed for use either temporarily in public places or as a stationary fixture in an entrance area. TI FeverScan consists of an intelligent IRSX infrared camera, a temperature reference body and a specially developed app. Further advantages: easy installation, fast measurement process (less than 1 second), mobile use. The result is shown graphically on the screen as a simple red-green display.

The so-called active thermography is used in many industries for non-destructive component testing. A heat source excites the components thermally and the heat energy flow through the material is reflected in the temperature distribution on the component surface. Abnormal distributions indicate defects such as air inclusions, detachments or microcracks. We offer ready-to-use solutions for

- Research and development (IRNDT) with modular structure for various materials and different excitation sources

- Production plants (C-CheckIR sensor) with compact NDT systems, suitable for robots for composite and other materials

- Maintenance (C-CheckIR) for mobile use on composite materials, primarily in the aviation industry

- Foamed components (dashboard check), mainly for detecting blowholes, for example in foamed dashboards of cars

- Zerstörungsfreie Materialprüfung (NDT): Thermografie-Lösung mit modularem Aufbau für diverse Materialien und unterschiedliche AnregungsquellenPDF / 431 kB

- Zerstörungsfreie Materialprüfung (NDT): Thermografie-Lösung für Produktionsanlagen mit kompakten Systemen, robotertauglich für Composite- und andere MaterialienPDF / 2.5 MB

- Zerstörungsfreie Materialprüfung (NDT): Thermografie-Lösung für die Instandhaltung bei mobilem Einsatz an VerbundwerkstoffenPDF / 587 kB

Camera Versions & Accessories

Compact version

- Convenient plug-and-play solution

- For WFOV lenses with standard thread

- Integrated air barrier for the lens

- Compact, robust full metal housing

- Protection class IP67

Universal version

- Very versatile solution

- Can be combined with almost any of our lenses with standard thread

- Compact, robust full metal housing

- Protection class IP67 with lens cap

Ex-proof version

- for explosion-proof zones 1, 2, 21, 22

- Protection class IP67

- Corrosion and heat resistant

- Lens window with anti-fog/anti-icing protection

OEM version

- Most flexible solution for customised configurations

- For integration of lenses with standard thread

- Housing integration kit available

- Protection class IP67 with corresponding housing

Lenses

- Wide angle lenses with focal lengths from 7.5 to 35 mm

- Exchangeable lenses with focal lengths from 6 to 100 mm

- Zoom lenses with focal lengths between 35 and 105 mm

- Microscope lenses with focal lengths of 60.20 and 60.27 mm

Further accessories are also available including the following:

- I/O panel for top hat rail mounting

- Various power, I/O or network cables

- Sun visors for protection against weather influences

Specifications

| Camera Model | IRSX-I336 | IRSX-I640 | ||

|---|---|---|---|---|

| Detector Resolution | 336 x 256 px | 640 x 512 px | ||

| Detector Type | Focal Plane Array (FPA), uncooled microbolometer | |||

| Special Range | 7.5–13 μm | |||

| Pixel Size | 17 x 17 μm | |||

| Frame Rate | 9 Hz | 60 Hz* | 9 Hz | 50/60/200 Hz (w/ windowing) |

| Object Temperature Range | Range 1: –25 to 135°C, range 2: –40 to 550°C, optional high-temperature range: 200–1,200°C (w/ ND filter) | |||

| Accuracy | ±2°C (±3.6°F) or ±2 % of reading (10–100°C @ 10–35°C amb) | |||

| NETD | < 30 mK (f/1.0, range 1) | |||

| Fixed Lenses | 7.5 mm, 9 mm, 13 mm, 19 mm, 25 mm, 35 mm | |||

| Interchangeable Lenses | 6 mm, 10 mm, 12 mm, 18 mm, 25 mm, 60 mm, 100 mm, zoom lens 35–105 mm, microscopy lens 20 μm | |||

| Configuration | Web interface | |||

| Areas of Interest | Spot, line, polyline, elliptical line, rectangular area, elliptical area, polygon area | |||

| Smart Realignment | Intelligent search and compensation algorithm to guarantee accurate temperature readings independent of e.g. machine or part tolerances | |||

| Temperature Evaluation | Min, max, mean, range, variance, standard deviation | |||

| Comparison Functions | Equal, less, greater, in range, out of range | |||

| Script Interface | Scripting w/ Lua | |||

| Ethernet Protocols | DHCP, DNS, GigE Vision, HTTP(S), mDNS, NTP, FTP, SSH, Modbus TCP, (MQTT (TLS), OPC-UA, PTP IEEE1588, Profinet (CC-A, RT-1), ONVIF)** | |||

| Ethernet Type | 10/100/1,000 MBit/s, Ethernet connector, 8-pin A-coded M12 connector | |||

| Image Streaming Protocol | GigE Vision w/ GeniCam, (RTSP)**, Ethernet image streaming, 16-Bit, 14-Bit, 8-Bit | |||

| Video out | Available on request | |||

| Digital Input | 2x electrically isolated; 5–24 VDC (max. 27 VDC), Encoder/resolver input, A+, A–, B+, B–; high-speed, dual RS-422/RS-485 receiver | |||

| Digital Output | 2x electrically isolated; 5–24 VDC, Analog output, 0–5 VDC | |||

| Digital I/O, Supply Voltage | 4.5–30 VDC, max. 100 mA, Analog input, 0–5 VDC | |||

| Protection Class | IP67 (IEC 60529), Bump, 200 g (IEC 60068-2-29) | |||

| Operating Temperature Range | –40 to 60°C (non condensing), Vibration, 4.3 g (IEC 60068-2-6) | |||

| Storage Temperature Range | –50 to 80°C(IEC 68-2-1 and IEC 68-2-2), RoHS, Compliant | |||

| Humidity | 0–95 % relative humidity (IEC 60068-2-30) | |||

| Dimensions | I55 x 55 x 77 mm (w/o lens, w/ connectors), Lens mount, M34x0.5, M34x0.75, M46x0.75 | |||

| Weight | 270 g (w/o lens), Base mounting, 4x M3 threaded holes (at all 4 sides) | |||

| Accessories | Adjustable mounting bracket, mounting adaptors, lens protection cap w/ Ge window, air barrier, terminal panel, protective enclosures (IRCamSafe series), focus tool | |||