Non-contact detection of velocity and length in converting, plastics and textiles

Precision measurement of length and speed is key for converting and textile production and distribution processes. Even the smallest deviation might cause added material costs that quickly add up. That is why high-precision non-contact measuring methords provide transparency and most of all process and cost-control.

Laser Surface Velocimeters (LSV) from Polytec are made specially for superior precision measurement of length and velocity in manufacturing processes. Polytec LSVs provide you with reliable measurement data from your production process an an integrated part of your process control system. Implementing LSV means increasing your precision and thereby the quantity and quality of your yield. Your advantages: Polytec's non-contact measuring technique works on almost all surfaces, removing any chance of damaging the measured product. From precision position monitoring in printing processes right through to cutting length control for packaging materials – Polytec systems ensure that you obtain the perfect configuration for every application.

ProSpeed® optical length and speed sensors measure with the utmost reliability around the globe and support the converting and textiles industry...

- in printing processes

- in laminating and coating systems

- and many more applications.

Downloads

Velocity monitoring and control

In converting, plastics and textile industries, Polytec LSVs are used for various speed measurements:

- Determining dwell time in coating and surface treatment systems

- Controlling cutting devices in cutting-to-length processes

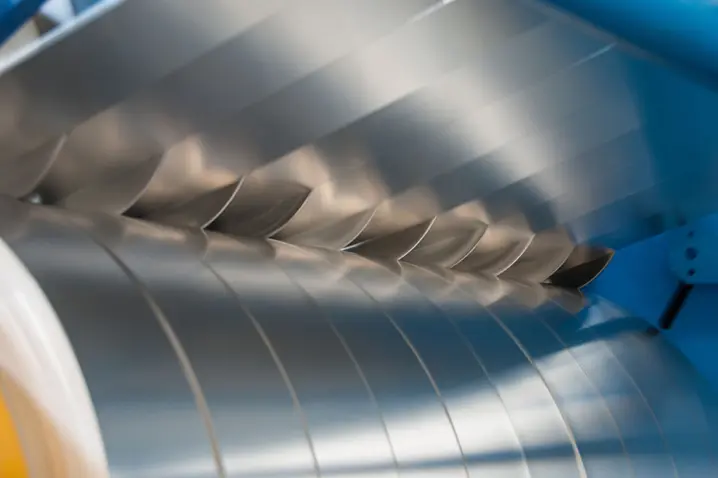

- Reel synchronization when winding web materials.

Conveyor and drive belt length measurement

In a specific case, a world leading manufacturer of conveyor and drive belts uses several Polytec LSVs for carrying out length measurements at cutting stations. This means that customer-specific cuts can be automated, simplifying the process significantly. The cut-to-length accuracy using the LSV is independent of the belt surface and achieves a precision of 0.1%.

Furthermore, Polytec industrial laser sensors are typically used for a variety of length measurement processes in the converting and textile industry:

- winding sheet materials

- cutting-to-length during fabrication

- position sensing in printing processes

Practical examples of velocity difference

Polytec LSVs are used for a variety of velocity difference measurements in the converting and textile industry:

- synchronization of individual sheets in longitudinal cutting processes

- synchronization of roll and sheet in winding and unwinding processes

- tension monitoring

Practical examples of tension control

Polytec LSVs are used in various applications in the converting and textile industry as a means of regulating tension:

- in joining sheet materials, i.e while changing rolls of film and packaging materials

- when processing sensitive material such as thin films

Industrial length and speed control with optical sensors

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters — get in touch with us today.