Optical measurement in cable and wire production processes

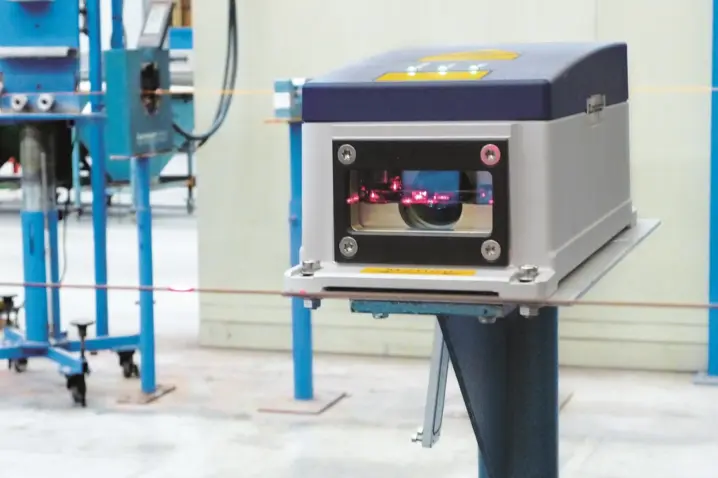

Precise, reliable and non-destructive length and velocity measurement is of the utmost importance when it comes to efficient manufacturing and processing in the cable and wire industry. The slightest deviations can cause added material costs, which can quickly add up. That is why high-precision non-contact measuring processes are essential.

Laser length and speed sensors, also called laser surface velocimeters (LSV) have specially been designed for accurate and reliable lenght and speed measurement in production processs. LSVs provide reliable measurement data that you can easily integrate into your process control systems. Using LSV means increased precision and thereby increased quantity and quality of your output. Polytec's non-contact measuring technique works on almost any surface and avoids damaging the produced good. From precision length measurement when winding cables right through to velocity measurement in coating processes for fiber optic cables – Polytec systems ensure that you obtain the perfect configuration for every application.

ProSpeed® optical length and speed sensors support the manufacturing of cable and wire...

- in wire drawing

- in insulating and sheathing lines

- in marking and printing processes

- and many more applications.

Downloads

Measure cable length with laser precision

Polytec LSVs are used for a variety of length measurement processes in the cable and wire industry:

- cut-to-length and winding of cables and wire

- position sensing in printing and marking processes

- winding coils

- in wire drawing

- in insulating and sheathing lines

Practical examples of velocity measurement

Polytec LSVs are used for a variety of velocity measurement processes in the cable and wire industry:

- dwell time determination in coating systems, e.g. for fiber optic cables

- cutting device control in cut-to-length processes

- coil synchronization when winding cables and wires

Practical examples of cutting length control

Polytec LSVs are used in the cable and wire industry to control cutting lengths in cut-to-length processes on cable, wire, sheathing and insulation materials.

Industrial length and speed control with optical sensors

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters — get in touch with us today.