Downloads

Reliable pressure measurement under all conditions

Opsens Solutions' fiber optic pressure measurement systems are based on white light interferometry technology. The measurement point is located at the end of the fiber.

Various interrogators and sensor types ensure that a wide range of applications and environments can be served. For example, excellent repeatability and reliability for industrial applications or resistance to microwave and RF environments, high temperatures, humidity, even underwater use, and other harsh environmental conditions.

The small size of the sensors and their EMC/RFI/MRI immunity make them ideal solutions for industrial applications.

Opsens OPP-M

Minimum dimensions and maximum industrial-grade

The OPP-M was developed for pressure measurements that require very small sensors with an outer diameter of 0.25 mm and excellent repeatability. In addition to minimal temperature shift, it also exhibits moisture-induced drift. The sensor offers reliable pressure measurement without phase delay and is insensitive to external MR / RF interference and changing electromagnetic environmental conditions.

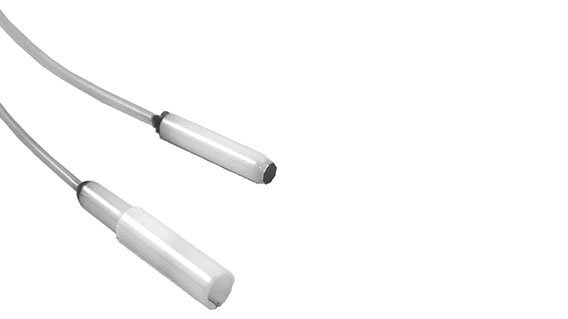

Opsens OPP-B

Highly durable with minimal dimensions

The OPP-B is a MEMS-based sensor for demanding applications. The model is a pure fiber optic pressure sensor (without metal housing) for applications requiring minimally invasive in-situ pressure measurement. The sensor offers long-term accuracy, durability, low drift and reliable pressure measurements in the harshest EMI, RFI and high voltage environments, flammable/explosive materials and high temperatures.

This compact and very robust probe can be customized to meet specific customer requirements. The fiber optic extension cable can be up to 3 kilometers long.

Opsens OPP-C

Submerged use at up to 1,000 PSI

The OPP-C, a MEMS-based fiber optic pressure sensor, is perfectly tailored for pressure monitoring in submerged and/or harsh environments. The compact and very robust pressure sensor can be specifically adapted to customer requirements. The fiber optic extension cable can have a maximum length of 3 kilometers. The sensor offers long-term accuracy, durability and reliable pressure measurements with a pressure range of up to 1,000 PSI.

It is the perfect piezometer: fully sealed and consisting of a stainless steel housing and diaphragm. It is designed for use in adverse temperature and pressure conditions and in toxic or corrosive environments and can be cast in place if required.

Thanks to the advantages of optical fibers, it is insensitive to electromagnetic interference, vibrations and lightning strikes that may occur in the measuring environment.

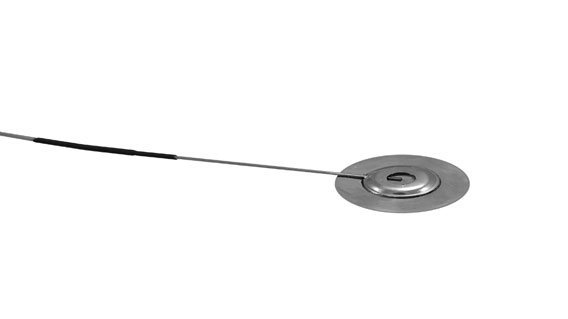

Opsens OPP-GF

Spot-weldable for turbines and pipe installation

The OPP-GF, a MEMS-based fiber optic pressure sensor from Opsens Solutions, is specifically designed for spot-weld installation. Its low and smooth profile is tailored for pressure monitoring applications in environments where fluid flow and aerodynamic forces must not interfere with a sensor.

The OPP-GF sensor offers long-term accuracy and durability with a pressure range of up to 700 kPa. It is particularly well suited for pressure monitoring of turbine blades, wind and hydraulic tunnels and penstocks. It is housed in a robust stainless steel housing and is designed for use in hazardous and corrosive environments.

The sensor can be installed with a fiber optic cable up to three kilometers in length. It can also be used on rotating parts such as the hub of a turbine shaft. Customized adaptations are possible.

Opsens OPP-GD

Robust & highly sensitive differential pressure sensor

The innovative OPP-GD is a compact wet/dry differential pressure sensor that measures both negative and positive differential pressure (bidirectional sensor). With a length of less than 100 mm and a diameter of less than 40 mm, the sensor can be easily mounted in limited spaces.

The differential pressure sensor combines two advantages: a very robust design that can withstand high static pressures in harsh environments and a high sensitivity to measure the smallest changes in differential pressure between two points of a pressurized system. Even at a static pressure of 30 bar, the sensor can measure millibar differential pressure fluctuations with an accuracy of 0.1 %.

The safe technology enables pressure monitoring in hazardous environments with explosive atmospheres. The fiber optic technology provides complete immunity to electromagnetic interference, vibration, high voltage, electrostatic surge and lightning.

The differential pressure sensor can be supplied with an integrated temperature sensor. The sensor requires no maintenance or calibration and is a true plug & forget system.

Opsens CoreSens

Versatile and scalable, supports WLPI and SCBG sensors

The readout system offers high-speed measurements with deterministic synchronization across many measuring channels. With its EtherCAT® interface, several CoreSens units can be combined to form a measuring system with up to 1,300 measuring channels.

The CoreSens unit consists of two-channel fiber optic measurement modules in a rackmount chassis.

- The WLX-2(S) modules based on WLPI technology (White Light Polarization Interferometry) are used with fiber optic sensors based on WLPI from Opsens Solutions to measure temperature, pressure, strain or displacement.

- The GSX-2 modules based on SemiConductor BanGap (SCBG) technology are used with fiber optic temperature sensors (OTG sensors) with SCBG technology from Opsens Solutions to measure rapid temperature fluctuations.

Both module types can be combined in a single housing. Each module has two fiber optic measuring channels with a sampling rate of up to 1,000 Hz and two analog outputs.

Versatile, modular and scalable

The CoreSens unit is the latest generation of interrogator systems from Opsens Solutions. The device is modular and scalable. Dual-channel measurement modules can be added as required.

Tailor-made for your needs

The CoreSens is available in a rackmount chassis configuration with up to 13 WLX-2(S) and/or GSX-2 dual-channel measurement modules. The master EtherCAT® (CSC-M) or bridge EtherCAT® (CSC-B) control interface module can manage up to 50 CoreSens chassis to provide complete control over a total of 1,300 measurement channels. A stand-alone configuration with a single WLX-2(S) or GSX-2 dual-channel measurement module is also available.

ServSens: for simple configuration and data acquisition

Opsens Solutions offers a simple and versatile web server application that is available with all CoreSens configurations. In the chassis configurations and with the CSC-M control module, the ServSens application runs in an embedded web server without the need to install any software on the customer's PC.

The ServSens application offers all functionalities for system, module and sensor configuration as well as real-time data acquisition and storage.

Versatile and open interfaces

For more flexibility, users can connect the CoreSens system to their own EtherCAT® network (with CSC-B module) or Ethernet network (with CSC-M module).

The open interface architecture allows users to develop and use their own application interface for an EtherCAT® or Ethernet-based communication link with the CoreSens device. SCPI-like commands for easy programming are supported by both interfaces.

EtherCAT capability

The EtherCAT® interface and EtherCAT® protocol are the best choice for true deterministic synchronization of high-speed and multi-channel measurements.

This provides a state-of-the-art industrial real-time fieldbus based on Ethernet in all rackmount versions of CoreSens products.

EtherCAT® is a registered trademark and patented technology licensed by Beckhoff Automation GmbH, Germany.

LogSens: CoreSens Stand-alone

The LogSens software is supplied with the CoreSens stand-alone system for use with the USB interface. LogSens offers all functionalities for the configuration of the system, the module and the sensors as well as for the acquisition and storage of data in real time.

Exemplary applications

By industry

- Civil engineering: Monitoring of civil and geotechnical infrastructures (bridges, dams, tunnels, mines, buildings)

- Military, aerospace: testing and monitoring of aircraft components

- Industry: automation and process control

- Energy: wind farm, nuclear environment, turbine instrumentation, high-voltage areas

- Oil and gas: offshore platforms, refinery and storage applications

According to parameters

Simultaneous and synchronized high-speed measurements of

- Temperature

- Pressure

- Strain

Displacement

Opsens FieldSens-W

Compact, robust and multi-channel for all fiber optic WLPI sensors

FieldSens-W is a compact and robust multi-channel interrogator system that can be used with all interferometric fiber optic sensors from Opsens Solutions, i.e. the WLPI sensors, for temperature, pressure, strain and position measurements.

FieldSens-W is based on White Light Polarization Interferometry (WLPI) technology. It is extremely versatile, supports a wide range of fiber optic sensors and offers a sampling rate of up to 250 Hz (with one active channel). A maximum of 32 modules with up to 12 channels per module are possible (up to 384 channels).

The device offers several interfaces for remote control and real-time data acquisition: EtherCAT®, 10/100 Base-T Ethernet, USB, RS-232 and CAN FD. The open interface enables easy integration into existing external data acquisition software. An optional portable touchscreen display is also available for stand-alone configurations (useful for on-site maintenance or remote locations). The device is equipped with an internal memory to ensure the necessary autonomy.

Features

- Compact and robust design

- Versatile thanks to modular design with up to 384 channels

- EtherCAT®, Ethernet, USB interface, RS-232 and CAN FD

- Can be used in the housing under outdoor conditions

- Supports a wide range of sensors

- Modular design enables both WLPI and GaAs technologies in the same system

Exemplary applications

- Geotechnical applications

- Civil engineering: Infrastructure monitoring

- Industry: automation and process control

- Portable or desktop devices

- High voltage conditions

- EMI, RFI and microwave environments

- Hazardous and nuclear environments

- Autonomous monitoring in remote areas

Opsens HandySens-W

Portable, highly reliable and multi-channel for all WLPI sensors

FieldSens-W is a compact and robust multi-channel readout system that can be used with all interferometric fiber optic sensors from Opsens Solutions, i.e. the WLPI sensors, for temperature, pressure, strain and position measurements.

The system is based on White Light Polarization Interferometry (WLPI) technology, supports a wide range of fiber optic sensors and offers a sampling rate of up to 250 Hz.

HandySens-W is equipped with a 5.0-inch touchscreen and can be battery powered for remote monitoring projects. The single-channel signal conditioner can be controlled directly via the touchscreen display or remotely via the 10/100 Base-T Ethernet interface and/or USB for real-time data acquisition. The device is equipped with an internal memory to ensure the required autonomy at remote locations.

Features

- Compact and robust design

- Portable, battery-operated device

- Sampling rate up to 250 Hz

- Large, practical touchscreen display

- Ethernet and USB interface

Supports strain, pressure, temperature and position sensors

Exemplary applications

- Geotechnical applications

- Civil engineering: Infrastructure monitoring

- Industry: automation and process control

- Portable or desktop devices

- High voltage conditions

- EMI, RFI and microwave environments

- Hazardous and nuclear environments

- Autonomous monitoring in remote areas

Opsens WellSens II

Multi-channel interrogator

WellSens Gen II is a robust and highly reliable multi-channel interrogator system. It is compatible with the Opsens OPP-W interferometric fiber optic pressure and temperature sensor for harsh environments. The WellSens Gen II can be operated in an ambient temperature range from -20 °C to +60 °C.

The wide operating temperature range and low power consumption make it ideal for remote applications powered by solar cells or generators. The modular DIN rail design allows for seamless expansion as requirements grow. The high precision, small footprint, fast sampling rates and ease of use make it the solution of choice for oilfield or industrial process applications.

Key features

- High linearity, precision and fast sampling rates

- Expandable up to 128 channels

- Modular DIN rail design

- Flexible - supports current and future WLPI products (P/T, displacement and strain sensors)

- Wide operating temperature range

- Low power consumption - <12 W for 2 channels (without display)

- Ideal for decentralized applications with solar panel

- Supports a wide range of interface and communication protocols, including RS485, TCP/IP and ModBus

- Application control - programmable alarms and I/O options

Exemplary applications

- Borehole measurements

- CO2 storage (monitoring of reservoirs)

- Downhole monitoring for thermal EOR (Enhanced Oil Recovery)

- Intelligent field instrumentation

- Hazardous and strong EMI/RFI/MRI environments