激光精确控制伸长过程

对于涉及拉长(延长)产品的加工步骤,测量和监控拉长程度非常重要,因为这对产品质量和进一步加工有重大影响。如果伸长率过低,则可能无法满足后续加工步骤的要求。另一方面,如果伸长率过高,则会对产品特性产生负面影响,最糟糕的情况是可能会损坏产品。为了确定伸长率,需要在加工步骤前后测量速度,并根据速度测量结果计算伸长率。

Polytec 激光传感器可实现非接触式伸长过程控制,从而提高产量并减少废品!

非接触式测量和伸长监测

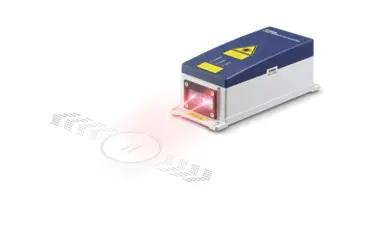

Polytec 的激光表面速度计(LSV)几乎可以测量所有表面,并且不易受到污染表面的影响,因此,特别适合使用它。非接触式测量技术可同时消除对精度产生的任何负面影响,例如滑移和磨损。进行测量的产品仍完好无损。速度测量精度的提高允许您更仔细地监测速度差和伸长率。因此,您可以更好地遵守终端产品的要求。结果:品质提升,同时减少浪费。

平整度和拉伸度测量

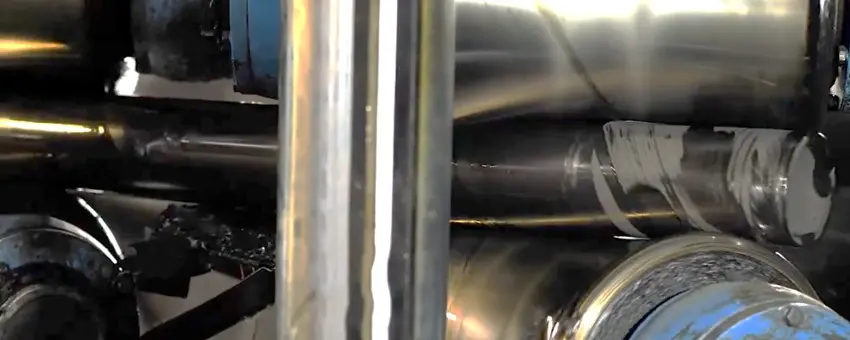

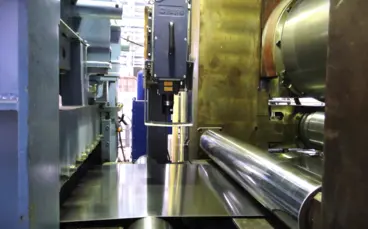

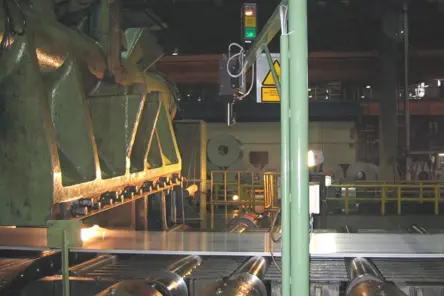

Polytec LSV 用于测量金属工业中平整机或拉伸机的平整度。冷轧平整机的平整度由轧钢机架输入和输出处的带钢速度差决定,而在过去是使用测速发电机进行机械测量。使用两个 Polytec LSV 可以防止滑动和磨损导致测量误差的发生,并且所测得的平整度可以用作调节轧钢的控制参数。通过使用 LSV,一位德国主要的不锈钢制造商证实其平整度测量的不确定性仅为 ±0.02%。

铝生产中的速度同步

在世界上最大的铝冶炼和轧制厂中,使用 Polytec 非接触式激光多普勒测量技术可同时测量制造过程中铝板的长度和速度。多个 Polytec LSV 集成在制造过程中,为工厂控制提供读数。

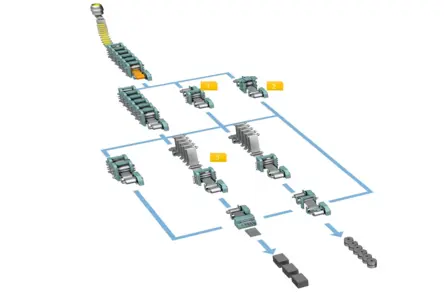

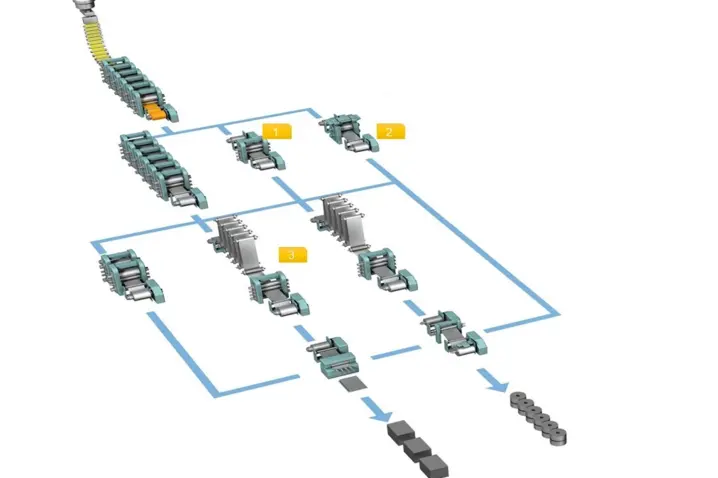

LSV激光表面速度计在伸长过程中的典型应用。

- 进出口速度测量,用于测量质量流量和反转冷轧机的伸长率控制。

- 20高辊轧机架的质量流量和伸长率控制的进出速度测量。

- 用于控制回火/皮辊轧机伸长率的入口和出口速度测量。

钢、铝和金属生产中的长度和速度的光学测量 (EN)

How to: Sensor integration & automation with PROFINET

Polytec has offered gateways for PROFIBUS, PROFINET and EtherNet/IP for many years. With PROFINET and EtherNet/IP integrated into the LSV sensor head, the interface allows not only the cyclic measurement data acquisition in real time, but also the acyclic writing of parameters and control of the laser. This application note describes the integration of the ProSpeed® LSV PROFINET interface into a Siemens PLC S7-300 using the project engineering software TIA-Portal, describing a step-by-step cyclic and acyclic data exchange.

与Polytec专家进行交流

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters — get in touch with us today.