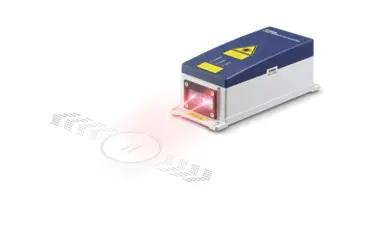

プロスピード光学式長さ・速度ゲージ

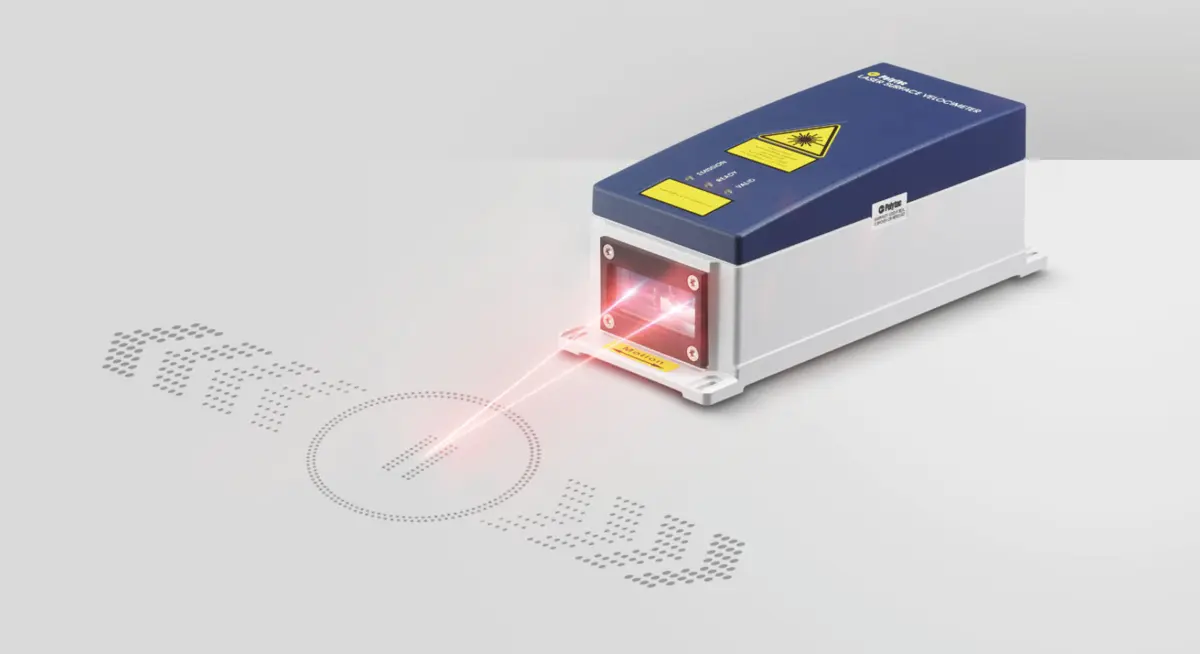

Speed gauges are essential for process control when producing strip material, e.g. in steel mills or paper manufacturing. Knowing the exact process speed and the derived strip length allows for optimizing any manufacturing process of sheet and endless material, for casting, rolling and more. Polytec provides a non-contact measurement alternative of laser-based speed gauges for reliable process control. Learn more about how ProSpeed® optical sensors will take your production process control to the next level and test us!

(送料別)

プロスピード スピードゲージの代表的な工業プロセス

スピード測定

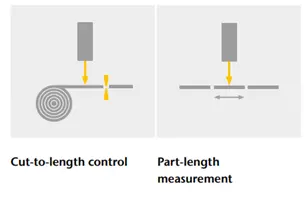

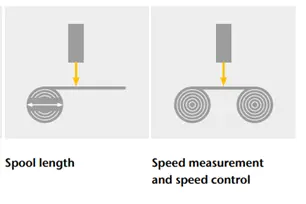

Process speed or velocity measurement is the basis for many steps in production processes such as cut-to-length control, depending on the manufacturing process sometimes speed synchronization, or differential speed measurement and more. In these processes, the ProSpeed® gauges use the laser Doppler effect for precise speed measurement, avoiding contact of the encoder with the good's surface and preventing slippage and wear, resulting in utmost precision and reliability in process control.

長さ測定

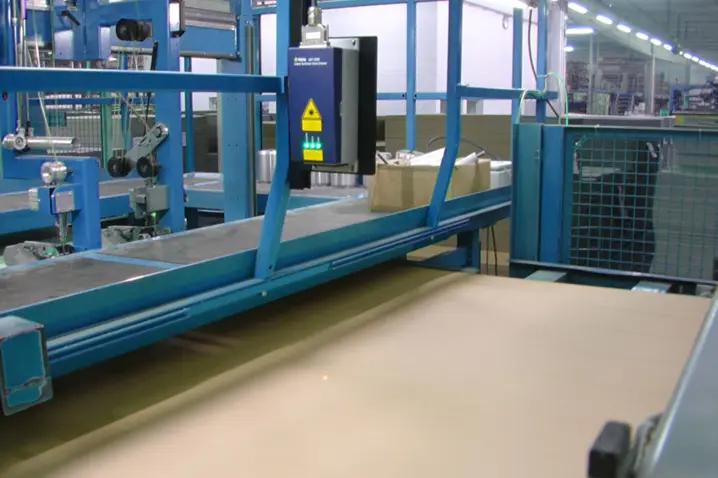

Whether in casting processes, rolling mills or any cut-to-length control, length verification of cut products such as rods, tubes, coils, panels and sheets, plate positioning in U- and O-presses for tubes, material tracking for sheet materials, winding sheet material up to position sensing and elongation... The number of speed and the respective distance traveled, are crucial for process control. ProSpeed® laser-optical gauges have become established devices in controlling production lines all over the world.

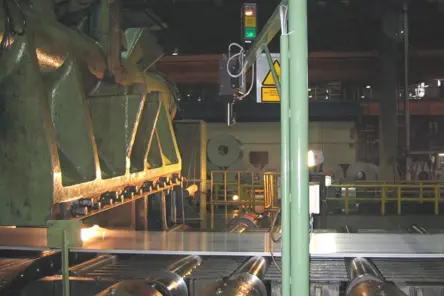

切断、鋳造、圧延用ゲージ

Providing electrical signals just like any classic encoders, Polytec speed gauges provide a seemless integration into any manufacturing line. Laser-based gauges show exceptional measurement performance in challenging conditions, for example when it comes to producing red-hot metals, handling material in humid, hot or dustry manufacturing environments. ProSpeed® gauges provide stable and all-time reliable measurement signal for continuous production, reducing measurement uncertainty caused by slippage or wear.

光学式スピードゲージが優れている点

プロスピード®スピードゲージは高性能光学式センサーで、従来のエンコーダー等の触覚式速度制御装置に取って代わり、プロセス制御における信頼性の高いインライン速度測定を実現します。 プロスピード®スピードゲージの非接触測定は、被測定面との接触を避け、スリップ、磨耗、材料の無駄などのバックドローを排除し、優れた測定性能を発揮します。 プロスピード®スピードゲージは、過酷な製造環境でも信頼性の高い性能を発揮するよう特別に製造されており、高温・低温(-20°~200°C)の両方に対応しています。

光学式スピードゲージの利点

//- スピードゲージは、インライン、前進、後退、停止を確実に測定します。

- 過酷で高温な環境向けのレーザー技術: IP66およびIP67、機械的衝撃および振動耐性認定済み

- 光学式スピードゲージは接触、スリップ、摩耗を回避

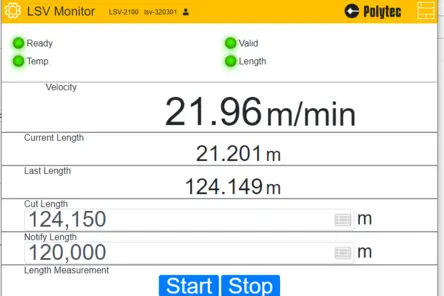

- ウェブ・インターフェイス、イーサネット、フィールドバス・プロトコルを備えた拡張接続性

- スタンドオフ距離3mの高い柔軟性

- マルチユーザーアクセス: イーサネット経由3 + シリアル1

- 最大200mmまでの優れた被写界深度、さまざまな距離を補正

- 3年保証、ゲージ交換プール、高速&オンサイトサポート

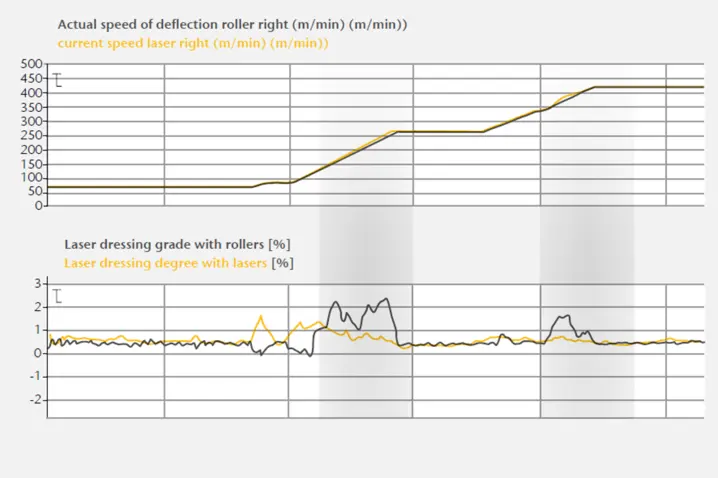

Why optical speed gauges promise more reliable process data

The image depicts a visualization of measurement data captured by a laser speed gauge system in the industrial process of cold rolling. The described changes in velocity or position of the sheet material allow patterns, indicating regular or periodic motions, fluctuations, or irregularities in the measured parameter. Based on this data input, the PLC can synchronize and harmonize all related process steps and regulate the mass flow process.

レーザー・ドップラー速度計の基本原理

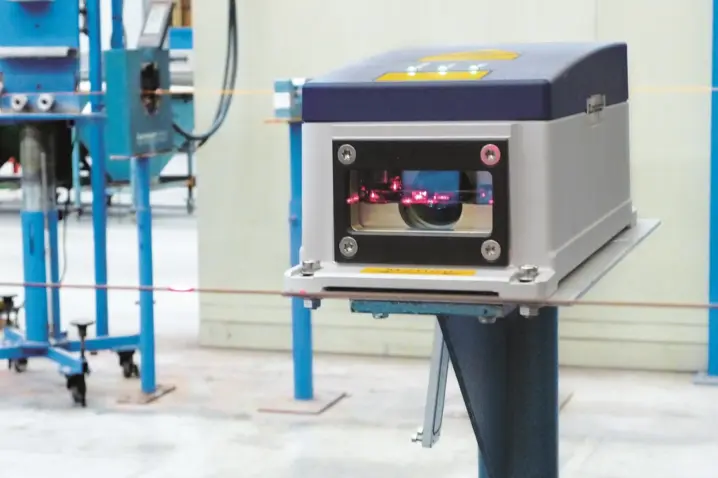

ProSpeed® optical speed gauges use the laser Doppler effect for evaluating the backscattered laser light from a moving object. Two super-imposed laser beams generate an interference pattern of bright and dark fringes on a monitored surface. As this surface of a sheet material in a manufacuring line moves through the fringe pattern, the intensity of the light scattered back results in a modulated frequency. This frequency modulation is measured by the photo receiver of the speed gauge, being directly proportional to the process speed or object velocity.

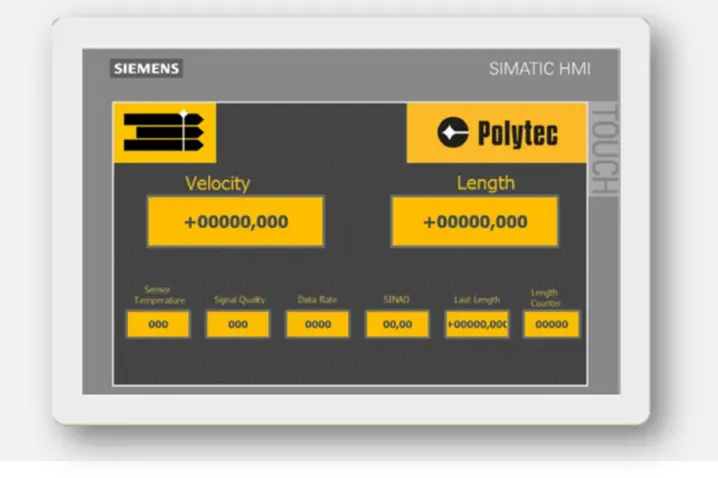

Profinet (Siemens PLC S7-300) を使用したプロセスオートメーション用スピードゲージ

The latest generation of ProSpeed® gauges come in a rugged design with an all-in-one integrated optics and electronics. The enhanced connectivity concept allows for a seemless integration into any production line. This application note describes the integration of the ProSpeed® LSV PROFINET interface for example into a Siemens PLC S7-300 using the project engineering software TIA-Portal.

Read about the product, the integration described for Profinet & Ethernet/IP, and custom sensor configurations for up to 3m long stand-off distances with large depth-of-field for varying distances.