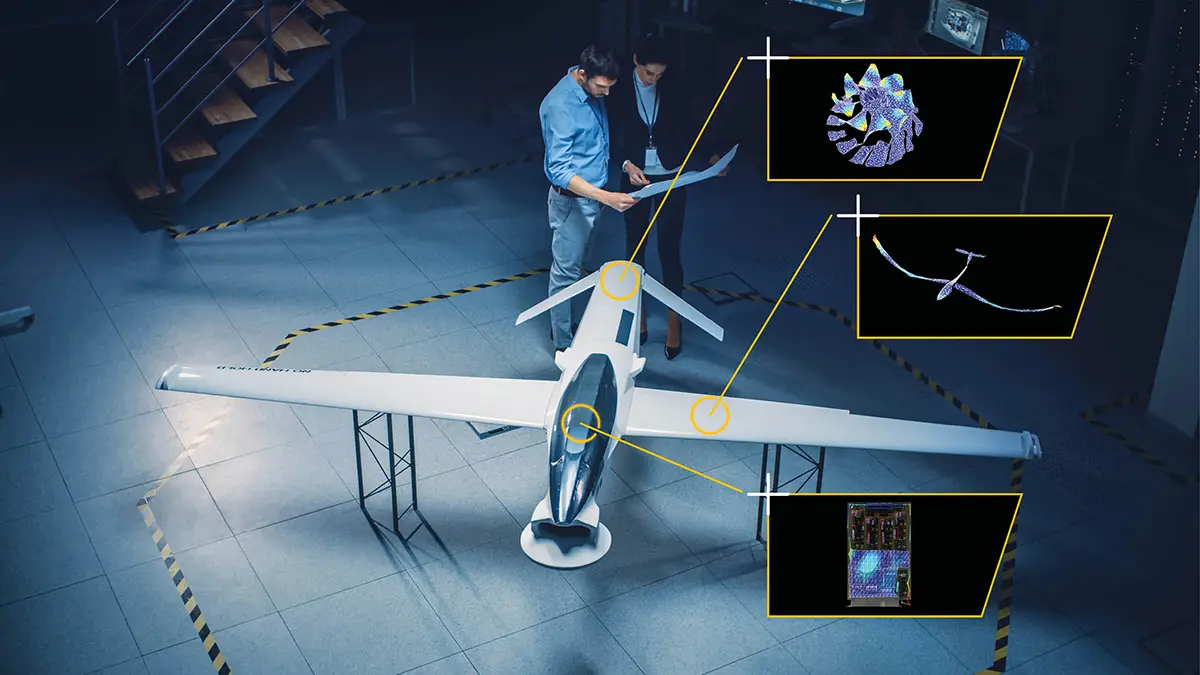

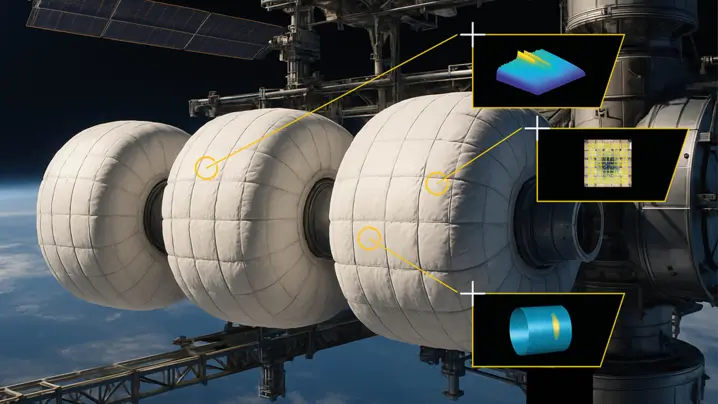

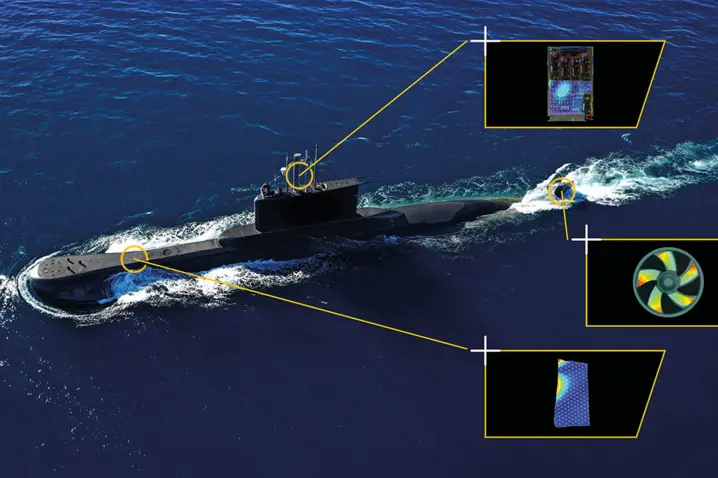

Delivering excellence means solving challenges earlier, faster, and with greater certainty. With non-contact, laser-based methods, your team can measure critical mechanical and electronic behavior with unmatched precision—without altering the structure or adding mass.

Measure critical vibrations caused by mechanical and electrical behavior:

- Natural frequencies and vibration modes.

- Acoustic signatures and noise sources.

- Strain peaks and structural responses.

Achieve mission success within a tighter timeline and with fewer prototypes. Across land, sea, and air weapons systems engineers consistently encounter:

- Hidden vibration and acoustic issues.

- Local resonances, dynamic coupling, and structural modes that aren’t visible in simulation alone.

- Limited access and harsh environments.

- Hot surfaces, rotating components, confined spaces, and live-fire environments where contact sensors are impractical.

- Data gaps between simulation and reality.

- Difficulty correlating FEA / CFD / digital twin models with physical hardware during design reviews.

- High cost of late discoveries.

- Finding problems during qualification, environmental testing, or field trials when changes can be the most expensive.

- Signal contamination and sensor influence.

- Traditional contact sensors can add mass, alter boundary conditions, or introduce noise, making it difficult to capture true behavior.

- Submerged and water-coupled measurement constraints.

- Capturing vibration data through or beneath water for naval and underwater systems is difficult with contact sensors and limited optical access.

We support your Mission

Polytec helps engineers uncover modes, resonances, and acoustic hotspots long before they become costly program delays. Our optical systems provide the clarity and access you need to make fast, confident engineering decisions.

These insights help you:

- Validate simulations with real data.

- Identify faults and failure points sooner.

- Reduce risk in development cycles.

- Improve robustness, performance, and reliability.

Typical discussion topics include:

- Optimizing vibration behavior of critical parts and systems.

- Increasing precision and overall performance of mechanical structures.

- Improving robustness through shock, impact, and environmental analysis.

- Shortening development timelines with early validation.

- Enhancing digital simulation model accuracy through precise real-world test data.

See the technology in action

We can walk your team through real-world defense, aerospace, electronics, and automotive examples, demonstrating how Polytec systems uncover hidden behaviors that traditional sensors miss.

Contact us for an on-site or virtual demo. We look forward to hearing from you!

Get in touch with our PolyXperts

Get in touch with our PolyXperts

Have a specific test in mind?

Share your application, and we'll recommend a measurement approach.

Laser vibrometry for measuring vibration, acoustics and dynamics

Polytec delivers non-contact, high-fidelity data without adding mass or fixtures, making it ideal for lightweight or sensitive defense structures. The same optical principles scale from MEMS and electronics to full airframes and ground or naval systems. This accelerates root-cause analysis by visualizing mode shapes and acoustic hotspots in 3D and quickly correlating with simulation. Throughout your project, Polytec application engineers provide expert guidance tailored to defense testing needs.

Can Polytec solutions be used in secure or sensitive environments?

Yes. Our systems are used in facilities with strict security requirements. We work under NDAs and align with your internal security and data-handling protocols.

Do I need optical measurement expertise to use these systems?

Not necessarily. Our applications engineers help with setup, training, and recommended workflows so your team can focus on engineering decisions, not just data acquisition.

What if I only need a single measurement or short-term project?

Depending on your region, we offer flexible access models such as service measurements, rental options, or long-term solutions—ask our team about PolyFlex.