Caractérisation optique de la dynamique sur les MEMS encapsulés

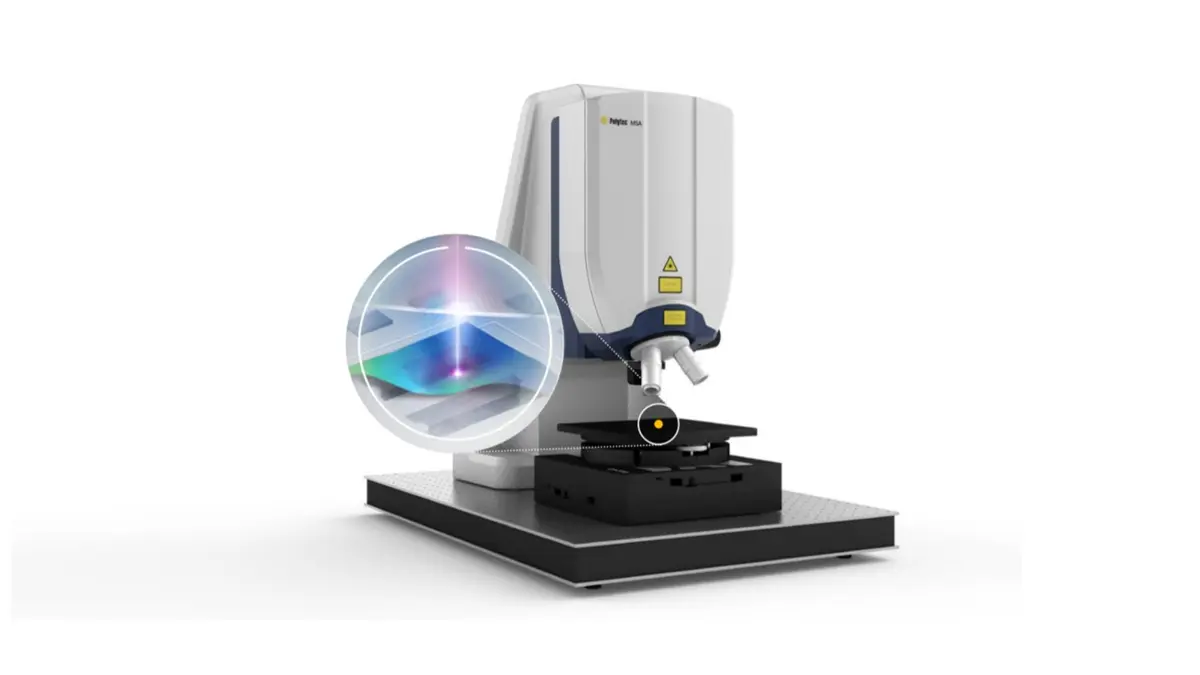

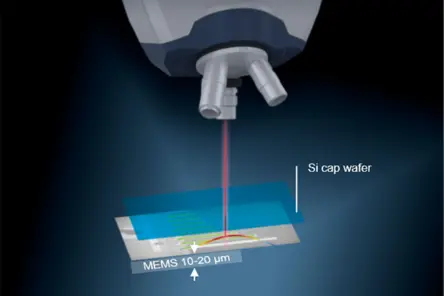

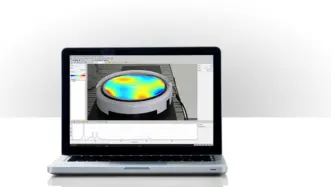

Dynamic characterization of MEMS devices to measure and visualize mechanical response is important for product development, trouble shooting and FE model validation. The MSA Micro System Analyzers from Polytec provide fast, accurate optical measurements of out-of-plane (OOP) and in-plane motion (IP). Until now, this has been limited to unpacked devices that are optically accessible. Now, the Polytec MSA-650 IRIS Micro System Analyzer allows even measuring through intact silicon caps on encapsulated microstructures like e.g. inertial sensors, MEMS microphones, pressure sensors and more.

Contactez nos experts

Contactez nos experts

Discutons-en ! Nous trouverons la solution la plus adaptée à vos besoins

Highlights

//- Mesure à travers différentes couches de silicium

- Mesure de réponse hors plan en temps réel jusqu'à 25 MHz (sans post-traitement)

- Résolution de déplacement hors plan sous-picométrique

- Validation simple du modèle FE de MEMS à l'état final

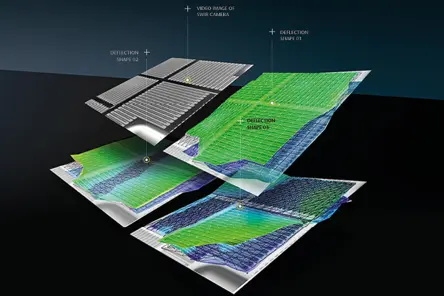

- Séparation supérieure des couches individuelles de l'appareil

- Microscope vidéo stroboscopique pour mesurer le mouvement dans le plan jusqu'à 2,5 MHz

- Système automatisé intégrable pour contrôle en production

Séparation supérieure des couches individuelles de l'appareil

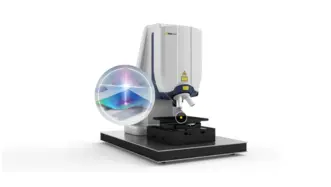

La solution de mesure complète du MSA-650 comprend notamment un contrôleur, un générateur de fonctions avec des voies de référence supplémentaires, un puissant logiciel de balayage optique et une tête optique avec une conception IR sophistiquée. Avec sa caméra IR dédiée et une source SLD à faible cohérence, c'est le premier système de mesure des vibrations plein champ pour capturer des couches entières d'échantillons à travers des capuchons en silicium dans des conditions de fonctionnement. Cette technologie d'interféromètre brevetée offre une excellente qualité de données grâce à une séparation supérieure des couches individuelles de l'appareil.

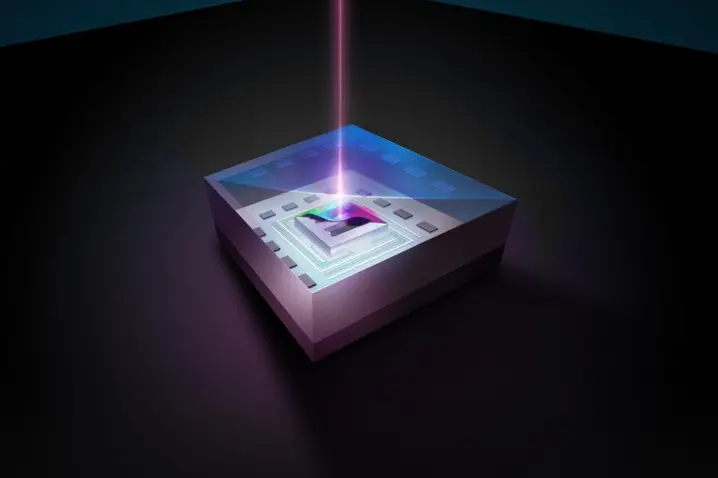

Analyse modale des MEMS encapsulés dans du silicium

Le silicium est transparent dans le spectre proche infrarouge au-dessus des longueurs d'onde de 1050 nm, la technologie sous-jacente de la mesure des vibrations basée sur l'interféromètre infrarouge ouvre la possibilité d'inspecter les MEMS encapsulés pour des résultats d'analyse authentiques et plus représentatifs. Le MSA-650 IRIS est le premier système de mesure au monde avec cette technologie de pointe pour visualiser la dynamique des dispositifs Silicium encapsulés. Ce tout nouveau système d'interférométrie breveté par Polytec offre désormais une qualité exceptionnelle des données en raison de la discrétisation des couches du dispositif MEMS mesuré. Avec une caméra SWIR dédiée et une source SLD à faible cohérence, le MSA-650 IRIS est le premier système de mesure au monde doté de cette technologie brevetée pour visualiser les dispositifs encapsulés avec du silicium, mesurer les vibrations dans le plan avec une résolution jusqu'à 30 nm et en temps réel vibrations hors du plan jusqu'à 25 MHz avec une résolution de picomètre et inférieure.

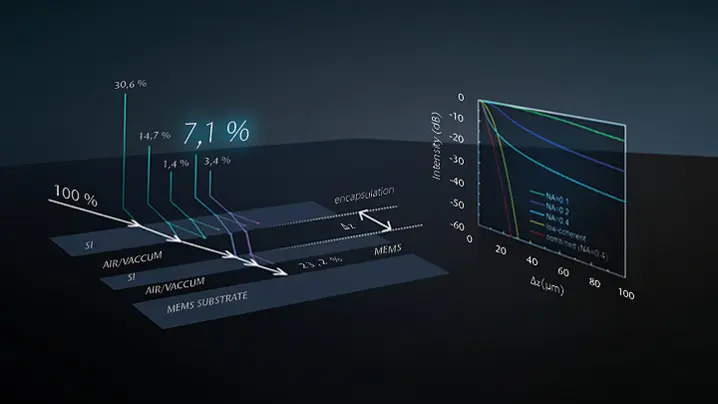

Utilisez la technologie de pointe dans l'analyse des vibrations

Afin d'utiliser la vibrométrie Laser Doppler (LDV) pour étudier les MEMS encapsulés, il est nécessaire d'étudier les propriétés optiques du silicium. Alors que le silicium est opaque pour la lumière visible, il montre une bonne transmission dans le proche infrarouge à partir d'environ 1050 nm. Une limitation pour la transmission cependant, est l'indice de réfraction élevé d'environ 3,4 à 1550 nm conduisant à des réflexions de Fresnel considérables aux interfaces limites.

L'innovation brevetée de Poyltec utilise une lumière cohérente courte pour améliorer la précision. Contrairement à la lumière laser, la faible lumière cohérente d'une diode à superluminescence n'interfère que si les trajets lumineux dans l'interféromètre sont équilibrés dans la longueur de cohérence de la source. Excluant ainsi la lumière de l'extérieur du foyer. Ce principe est utilisé dans les interféromètres à lumière blanche ou pour la tomographie par cohérence optique et maintenant pour la première fois dans la vibrométrie laser Doppler (LDV). Permettant le balayage des mesures LDV avec une bande passante de 25 MHz et une résolution d'amplitude de 100 fm/√Hz sur des MEMS encapsulés.

Caractérisation optique MSA-650 IRIS des MEMS à capuchon en silicium

Découvrez les capacités uniques du vibromètre laser Doppler IRIS Polytec MSA-650 pour la mesure précise et sans contact des dispositifs MEMS encapsulés. Voyez comment la technologie IR avancée permet une analyse précise des vibrations même à travers des matériaux difficiles.

Downloads

Accessoires et composants

A-MOB-xxxx : Objectif champ clair

Pour la mesure des vibrations hors plan et dans le plan. Grossissements disponibles : 2.5x, 5x, 10x, 20x, 50x.

A-STD-TST-01 : Banc d'essai

Banc d'essai offrant un grand espace de travail. Avec axe z motorisé, course 200 mm.

A-STD-BAS-02 : Banc d'essai

Support rigide pour la tête du capteur. Comprend un bloc de mise au point manuelle avec une plage de déplacement de 100 mm avec un entraînement grossier et fin. Interfaces avec les tables optiques disponibles dans le commerce.

A-STD-F50 : Bloc de mise au point

Plage de déplacement 50 mm. Avec entraînement grossier et fin pour le réglage manuel de l'axe z de la tête du capteur. Interfaces avec les stations de sonde de wafer disponibles dans le commerce.

A-TAB-AIR-01 : Table anti vibration active

Table anti vibration à amortissement pneumatique avec réglage actif du niveau. Compatibilité : banc d'essai A-STD-TST-01, support de base A-STD-BAS-02.

A-TAB-ELC-01 : Table anti vibration active

Stabilisation de la bobine acoustique à commande électronique pour des performances d'isolation maximales. Compatibilité : banc d'essai A-STD-TST-01, support de base A-STD-BAS-02.

A-BBO-ME02 Breadboard

Breadboard avec motif de trous métrique. Empreinte 900 mm x 600 mm. Compatibilité : support de base A-STD-BAS-02.

A-AVI-MELA : Breadboard d'isolation active des vibrations

Contrôlé électroniquement des performances d'isolation vibratoire les plus élevées. Avec motif de trous métrique. Empreinte 600 x 800 mm. Compatibilité : support de base A-STD-BAS-02.

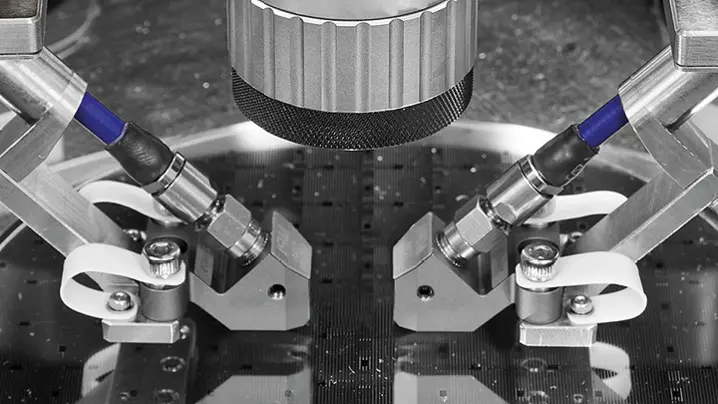

A-SPK-0008 : Module de sonde de Wafer

Avec l'étage de positionnement XY A-PST-200P, le module sondeur de wafer forme une plate-forme motorisée pour la mise en contact électrique et la mesure de haute précision de plaquettes et de substrats jusqu'à 200 mm de diamètre.

A-SPK-0010 : Module de sonde à vide

Accessoire sous vide et ligne de purge. Micro-manipulateur pour la manipulation de quatre sondes électriques.

Produits associés

MSA IRIS service de mesure

Cette toute nouvelle technologie de mesure brevetée permet une analyse complète et représentative des MEMS encapsulés en Si, en mesurant la dynamique à travers les bouchons en silicone. Nos PolyXperts sont impatients de recevoir vos échantillons pour des tests modaux, des études de faisabilité et vous conseiller à toutes les phases, du développement au prototypage en passant par la fabrication de vos microstructures encapsulées.

Analyseur de microstructures MSA-600

Système de mesure tout-en-un pour la caractérisation 3D statique et dynamique des MEMS et des microstructures - maintenant jusqu'à 8 GHz. Le MSA-600 améliore les processus de développement et de contrôle qualité. Intégré aux stations sous pointes disponibles dans le commerce, il permet des tests au niveau des wafer.

Analyseur de microstructures 3D MSA-100

L'analyseur de microstructures saisit simultanément des composantes vibratoires dans les trois directions spatiales. Le système de mesure optique permet une analyse vibratoire 3D à haute résolution du courant continu jusqu'à 25 MHz avec des résolutions d'amplitude de l'ordre du sous-picomètre, pour les composantes vibratoires dans le plan et hors du plan.

Logiciel PSV

Le logiciel PSV est le cœur de chaque vibromètre laser à balayage Polytec. Ce logiciel complet permet l'acquisition, l'affichage et l'édition rapides et simples des données de mesure des vibrations recueillies avec tous les vibromètres à balayage PSV, avec la gamme d'équipement pour les microstructures MSA pour les observations microscopiques ou avec la station de test automatisée RoboVib®.

Pas de budget ? Mesurez tout simplement.

Que vous ayez besoin de prestations de mesure, de location d’équipement ou de leasing sur mesure, notre offre de service PolyFlex répond à vos objectifs techniques tout en s’alignant sur votre stratégie financière. Idéal pour les projets de courte durée, les besoins ponctuels ou les budgets limités.

Avec PolyFlex, vous obtenez des résultats sans compromettre vos délais ni votre budget.