Control epoxy die bonding by surface characterization

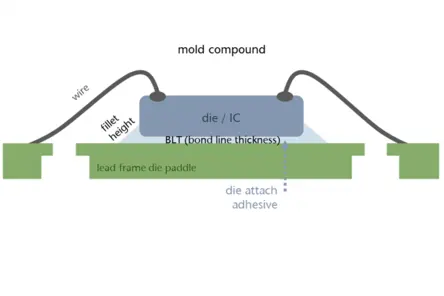

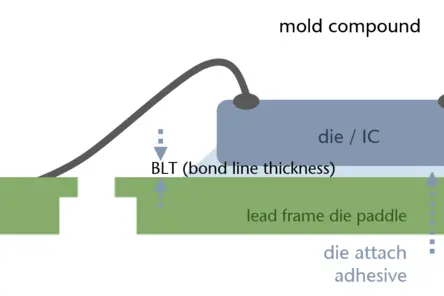

In epoxy die bonding and related die attach processes, even small deviations can affect process stability, component reliability, and lifetime. Key quality indicators such as bond line thickness (BLT), die tilt, and positioning accuracy must therefore be monitored reliably and reproducibly.

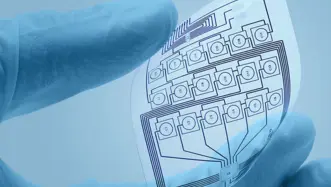

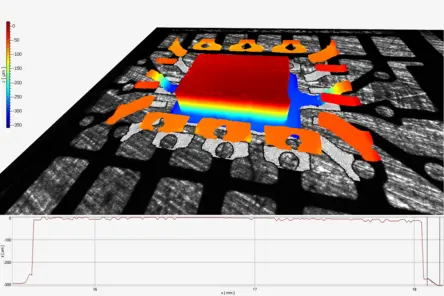

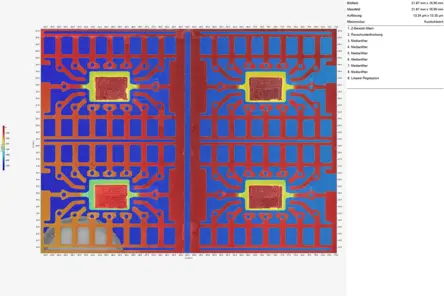

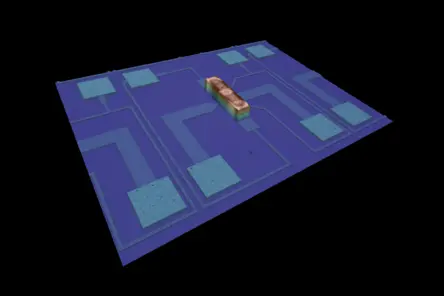

Polytec’s TopMap optical surface profilers enable fast, non-contact inspection of epoxy die bonding processes. They provide precise 3D surface data for automated quality control — from die orientation and tilt to bond line thickness — directly in production environments.

Characterizing QFN packages (quad-flat no-leads)

TopMap 3D surface metrology solutions integrate easily into production lines and deliver automated, high-resolution in-process measurements for epoxy die bonding. Typical inspection tasks include:

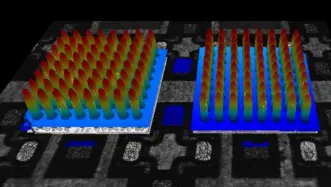

- Die tilt and die positioning

- Bond line thickness (BLT) and BLT height

- Torsion and relative positioning to reference features

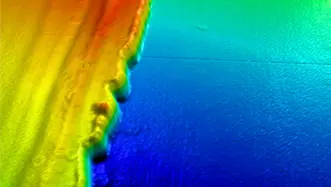

In QFN packages, the die attach fillet — the adhesive excess rising along the die edges — plays a key role in mechanical stability. Based on precise BLT measurements, relevant parameters such as fillet width, height, and slope angle can be evaluated and optimized to improve process robustness and component quality.

Bond line thickness, film and layer thickness measurement in 3D

Fitting surface profiler

Micro Profiler

Micro.View profiler systems are optimized for measurements with sub-nanometer resolution. With focused optics and high vertical resolution they enable detailed analysis of microstructures, surface finish and material distribution where even the smallest deviations matter.

Macro Profiler

Pro.Surf with its areal topography scanning determines form and flatness faster. Its telecentric optics with large Z range reaches holes and recessed surfaces. The largest FoV and True Stitching handles big samples and multi-sample measurements with ease. Upgrade to Pro.Surf+ and also analyze roughness all-in-one.

Metro.Lab

Metro.Lab is a compact, wide-area surface profiler. It combines high measurement performance with a small footprint—ideal for space or budget conscious applications that still require reliable 3D surface data.

Choose the right surface profiler with confidence—benefit from our "try before buy" approach.

Related applications and measurement tasks

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.