Measure form, flatness & roughness on lenses, optics, mirrors

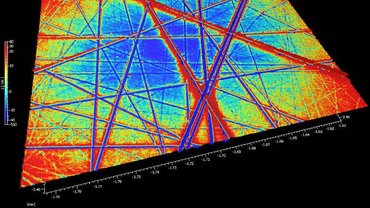

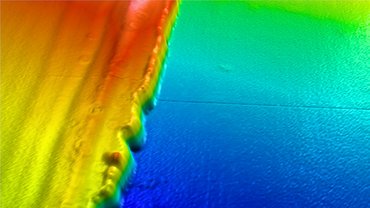

Measure surface form parameters, evaluate flatness or step-height on optical components, glass and transparent media. TopMap surface profilers allow for complete and fast inspections of lenses, optics, free-form surfaces or mirrors for design optimization and quality control in manufacturing. Transparent materials such as optics, mirrors, or lenses are challenging materials to measure due to its sensitivity to scratches or defects (tactile measurement) and reflectivity (optical measurement). Prevent from scratches or influences of tactile measurement tips by using non-contact optical measurement technology. The large area topography scanning of Polytec enables capturing entire workpieces or larger areas in one shot. The elaborated SST Smart Scanning Technology also copes with measuring different and challenging surface reflecitivies, providing reliable measurement performance on dull, matt, coated and shiny surfaces.

Typical optics applications for TopMap optical profilers are:

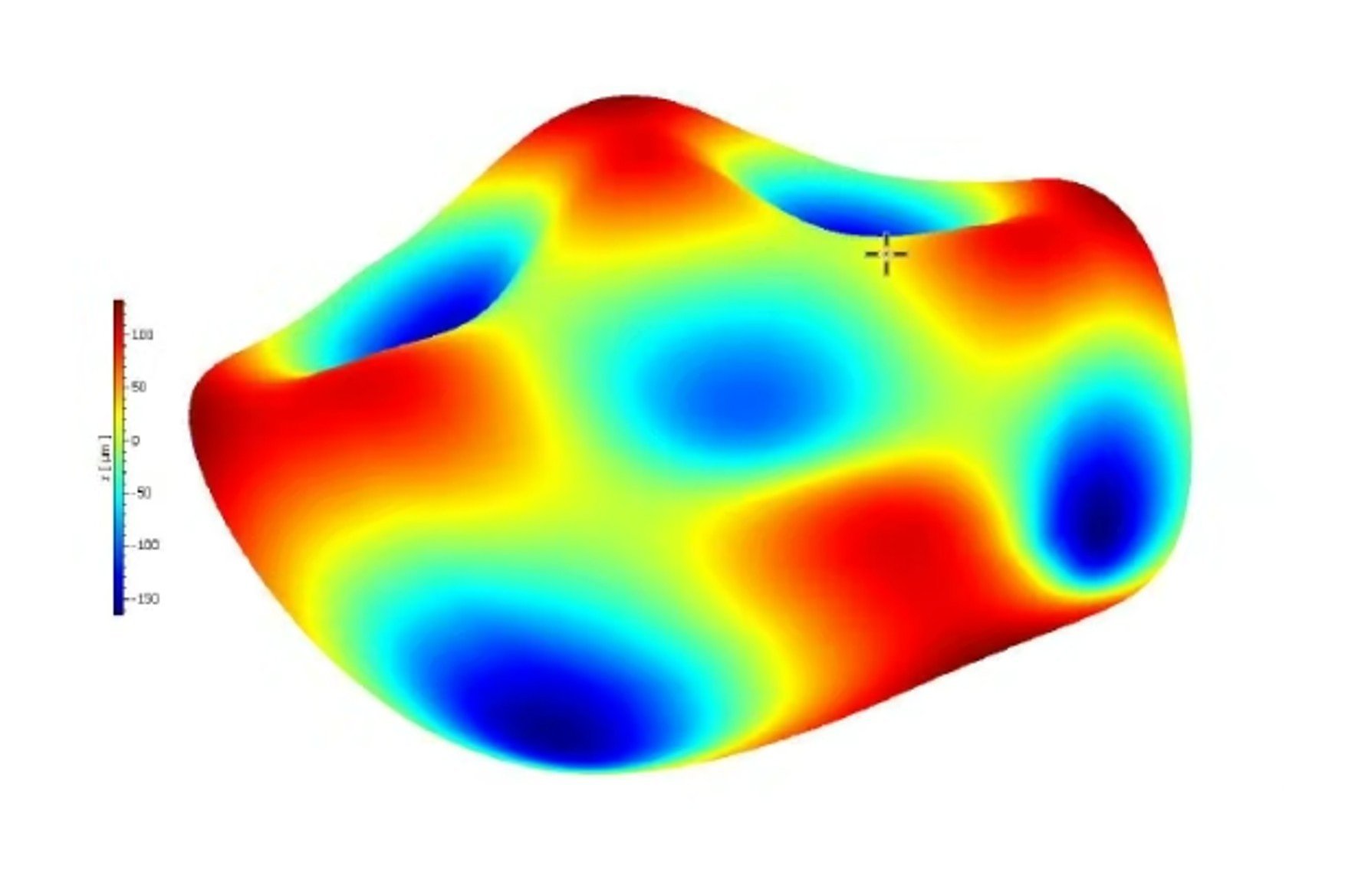

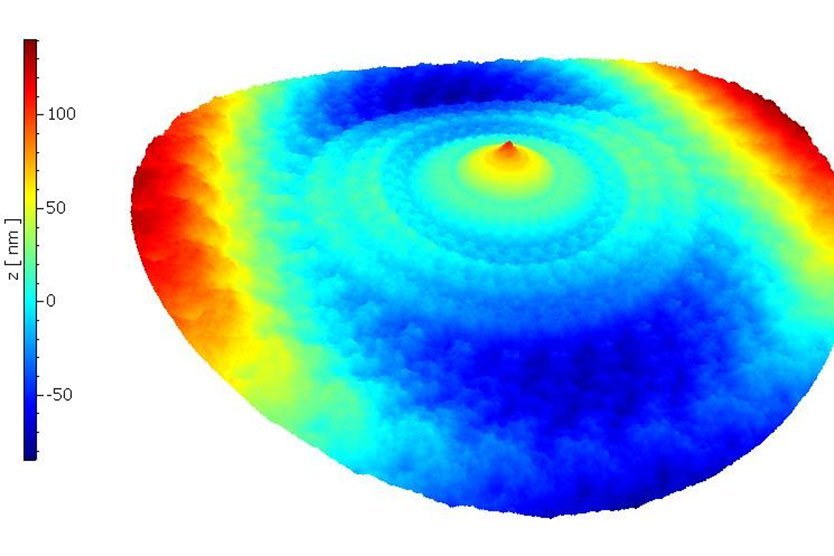

- Flatness measurement of mirrors

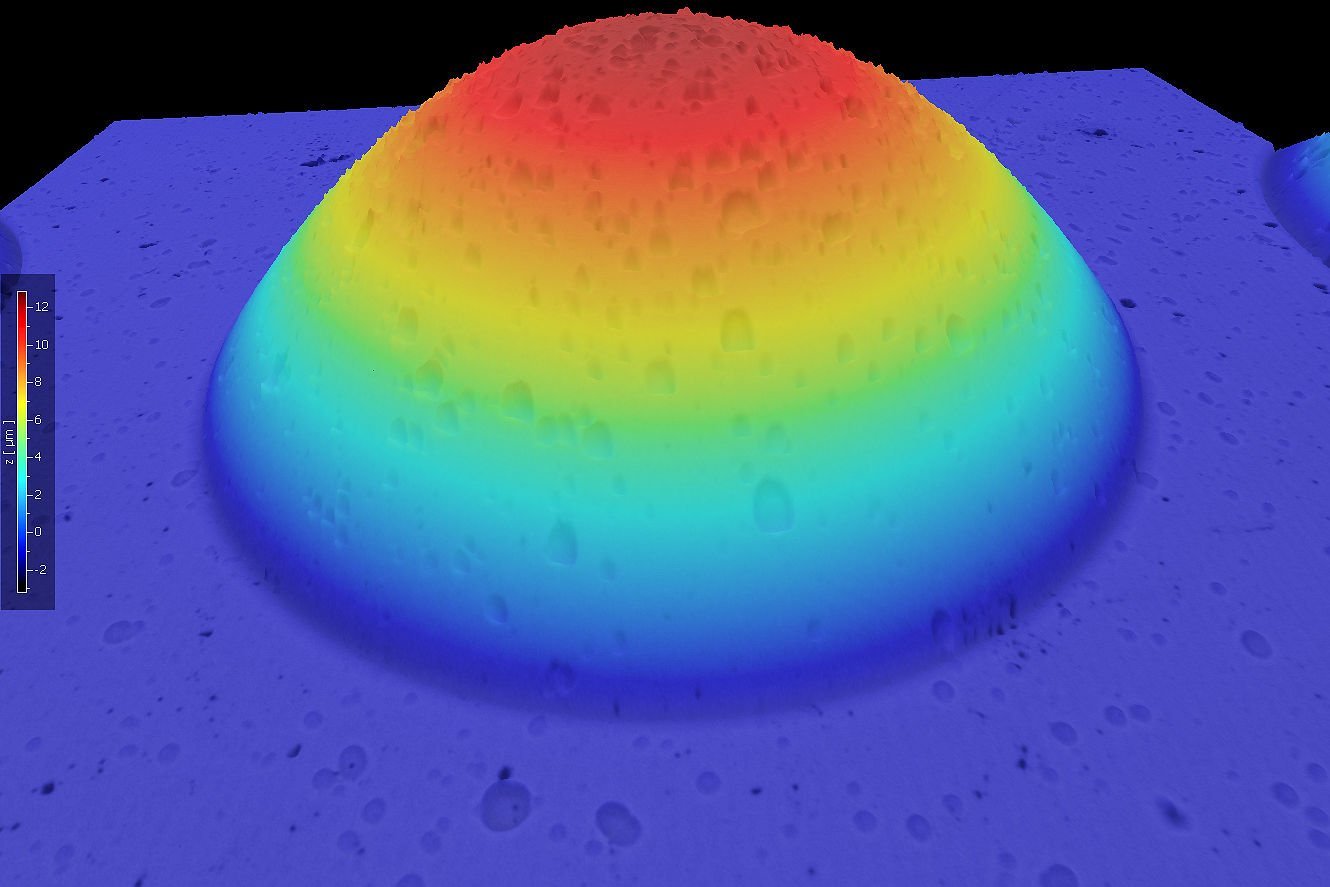

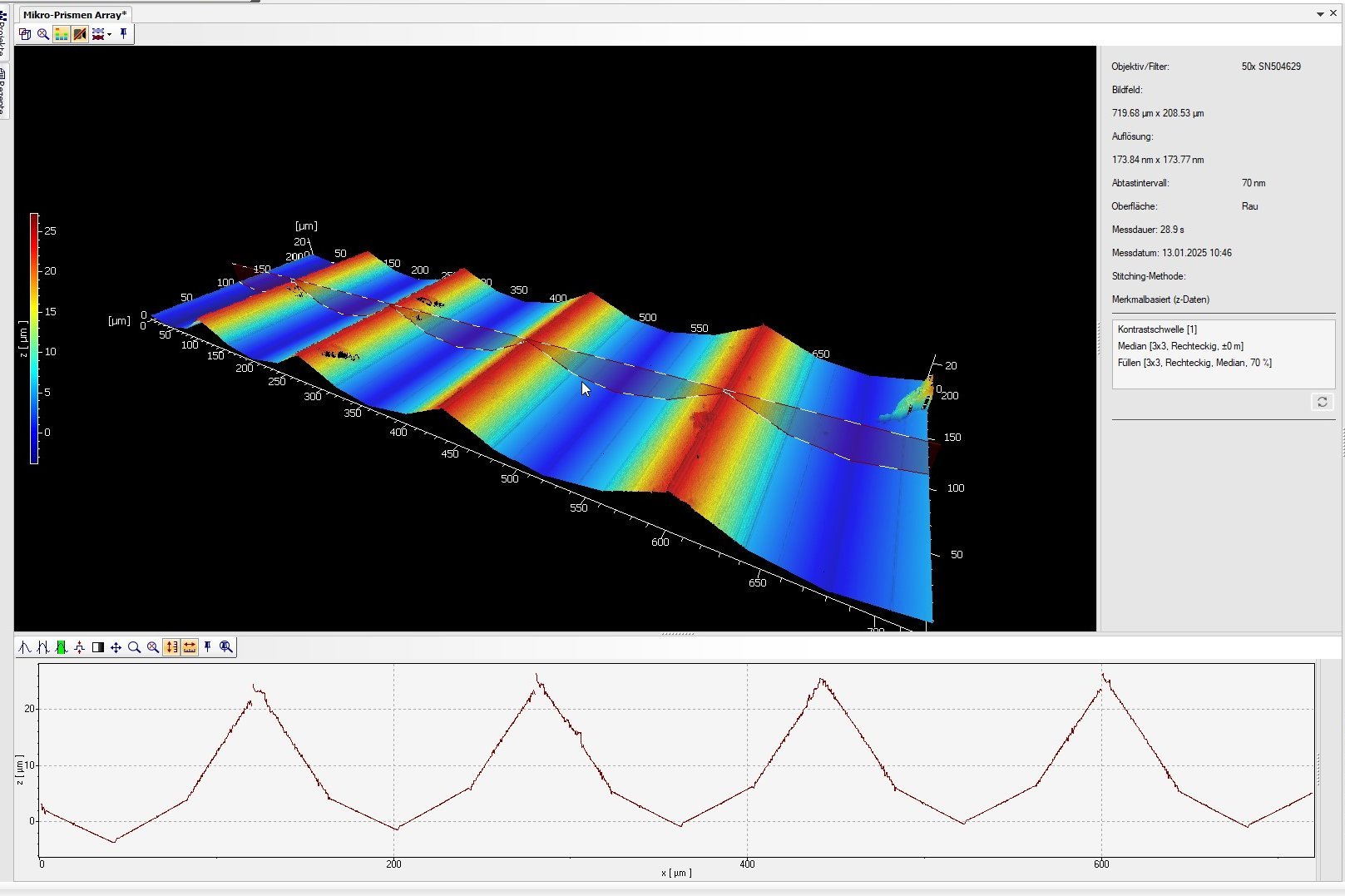

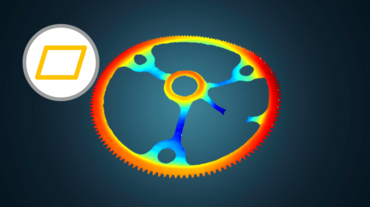

- Complete 3D characterization of lenses and free-forms

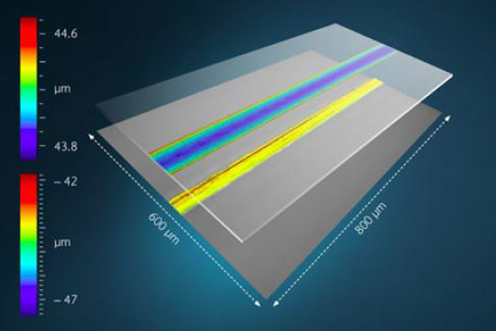

- Warpage measurement on thin films or layers

- Layer thickness measurement

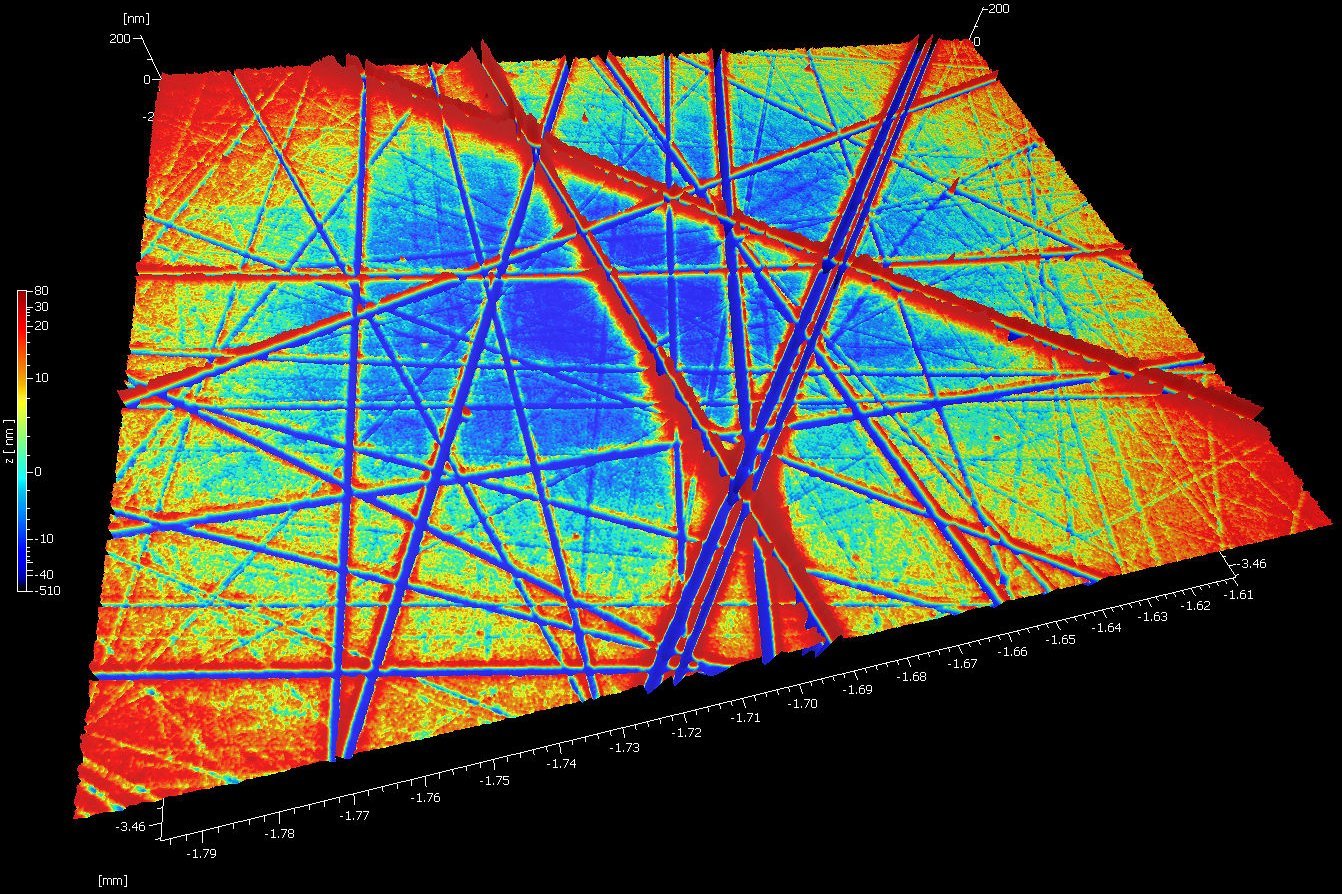

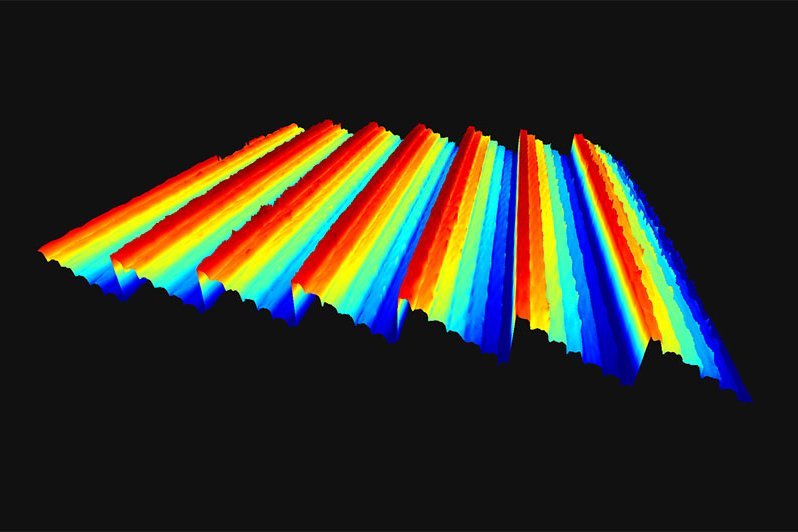

- Separated inspection of form, waviness and texture

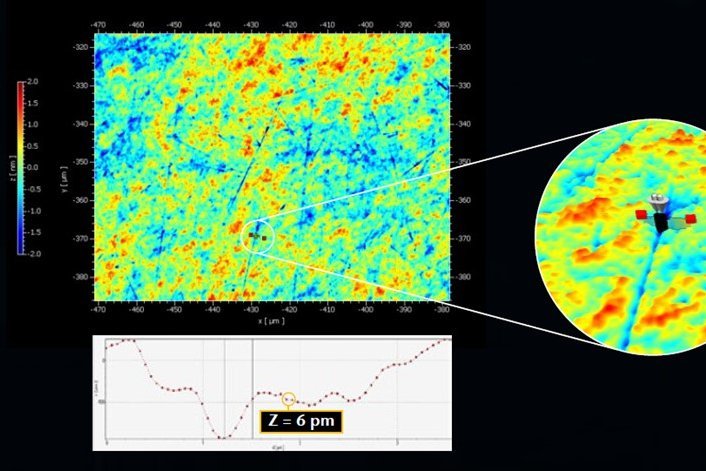

- Roughness and microstructure analysis in sub-nm range

- Defect detection and evaluation related to scratch testing

- Step-height measurement on precision mechanics such as mirror or lens holders

- Form tolerance check of optical precision equipment (lasers, interferometers etc.)

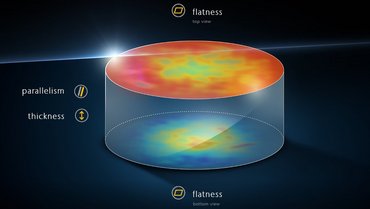

- Combined measurement of Flatness-Thickness-Parallelism of top and bottom surface in one shot