No budget? Just measure.

Whether you need contract measurements, equipment rental, or leasing, our scalable services deliver precise data—without the overhead of major investments. Ideal for short-term projects, occasional use, or limited budgets. Get in touch with us—together we will find the right solution for your specific needs!

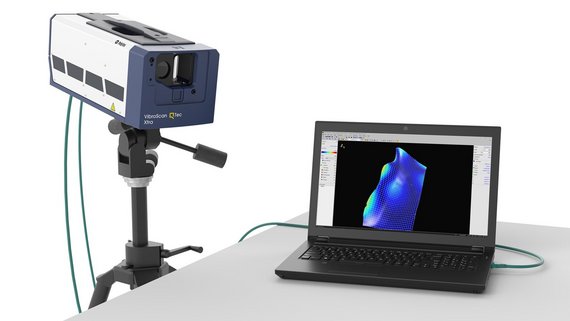

VibroScan QTec

With the new VibroScan QTec we push reliability, flexibility and speed to the next level. With IR or HeNe even the toughest measurement tasks can be mastered in your product development, quality assurance or research projects.

Measure in 1D or 3D up to 10 times faster and with increased signal quality thanks to the patented QTec® technology.

Areas of technology

Vibrometry

Laser vibrometers developed and manufactured by Polytec define the globally recognized standard for optical vibration measurement. We provide our customers from a wide variety of industries a comprehensive range of solutions for almost any vibration-related challenge in research, development, production and condition monitoring. Laser Doppler vibrometers are precision measuring instruments for the examination of objects of almost any size and solve your task quickly, in a non-contact, non-destructive manner.

Velocimetry

When producing continuous material and piece goods, knowing the exact length and velocity is key if you are to optimize your costs and processes. Non-contact laser surface velocimeters make reliable process control possible, based on the laser-precise measurement of length and speed, even in harsh ambient conditions. Designed for their robustness, reliability and minimum maintenance requirements.

Surface Metrology

TopMap is the line of optical surface metrology systems by Polytec, characterizing precision-manufactured surfaces in a non-contact, fast and areal way. TopMap wlhite-light interferometers provide repeatable and reproducible measurements of form parameters, roughness, microstructures and more. With a 4 year warranty and strong commitment to service & support, TopMap surface metrology drives the transformation of industrial manufacturing and quality control. Together we turn 3D topography data into your manufacturing and process knowledge.

Optical Systems

The field of optical systems comprises the greatest variety at Polytec, both in terms of technology and products: from optical, electro-optical and electrical measurement technology for laboratory, field and production applications to optical sources across all spectral ranges. In this huge photonics product range, we always keep track of what’s going on: our consulting engineers and service technicians will find the optimal measurement solution for your specific measurement task.

Process Analytics

Reducing costs while increasing quality, efficiency and output: Polytec provides spectroscopic measurement solutions for a wide range of routine analytical and/or industrial applications, from incoming material inspection through manufacturing processes and final product quality control. Fast, robust and precise near-infrared (NIR) spectrometer systems allow to determine the chemical composition and concentration of materials non-destructively and in real-time. This established technology is implemented in numerous industries for quality control applications.

ProSpeed®: Optical length & speed sensors with enhanced connectivity

No contact, no slippage, no wear: ProSpeed® optical encoders measure reliably even on red-hot metals up to over 1.000°C, enabling reliable length verification, position tracking, speed synchronization and superior cut-to-length control. This new generation Laser Surface Velocimeters come with enhanced connectivity, multi-user access for up to 4 users, Ethernet/IP or Profinet protocols or classic analog or digital signals for PLC.

Polytec events

Visit Polytec around the world at trade fairs and conferences, or sign up to one of our online seminars, user meetings or customer seminars to find out more about the principles, advantages and various uses of optical measuring technologies!