精准测定材料疲劳特性

在工程领域,若想通过仿真模型作出精准且可靠的预测,尤其是针对产品使用寿命的耐久性评估,获取精确无误的材料参数是基础且关键的一环。以汽车工程、医学及能源技术等行业为例,相关结构在其预期服役周期内,由于高频应力作用,或是历经长达 30 年的长期运行,往往需承受超过千万次的载荷交变。这一工况范畴已进入超高周疲劳(VHCF)区间,远远突破了传统 S-N 曲线所覆盖的范围。所以,对于那些旨在投入超高周疲劳工况下稳定运行的高性能部件而言,深度洞悉所采用材料的疲劳特性,无疑是确保其可靠性的核心要点。

为在不超过一个月的合理时长内,实现高达 100 亿次(1010)的高载荷交变测试,通常会将测试样品置于千赫兹频段的共振振动环境中开展试验 。

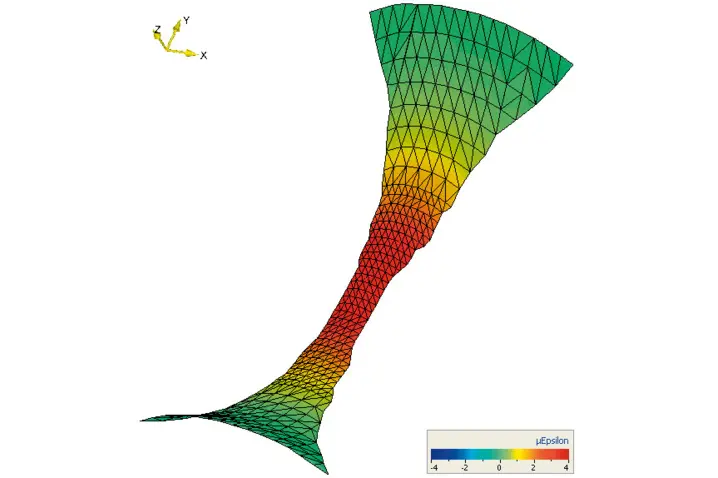

测量应力、应变以及固有模态

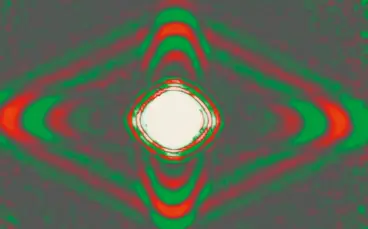

在模型验证领域,德国 Polytec 公司的三维扫描式激光测振仪提供了一种极为直接有效的手段,能够精准测量真实疲劳样品的固有模态与固有频率。这一特性对于确保模拟模型与实际样品的高度契合、提升模型预测的准确性具有重要意义。

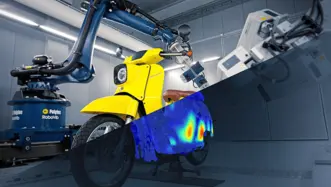

该技术的另一潜在应用领域聚焦于高频应力与应变分析。鉴于应变片等传统接触式测量手段在面对此类耐久性应力测试时存在局限性,无法满足精确测量的需求,Polytec 三维扫描式激光测振仪的非接触测量优势便得以凸显。其能够突破接触式测量的束缚,对高频应力和应变进行精确捕捉与分析,为相关研究提供可靠的数据支持。

不仅如此,在高应力工况下的关键部件运行可靠性测试中,Polytec 的这一技术同样大显身手。例如在高应力列车部件(如轮辋)的可靠性评估中,能够精准监测部件在复杂运行条件下的振动特性与应力分布,提前预判潜在故障风险;在风力涡轮机这类大型设备的运维检测中,助力工程师全面了解设备结构在强风载荷下的动态响应,保障其稳定运行;在医疗技术领域,针对超声手术刀等精密器械的性能测试,通过精确测量器械工作时的振动参数,确保其在高频振动工况下的可靠性与安全性 。

相关产品

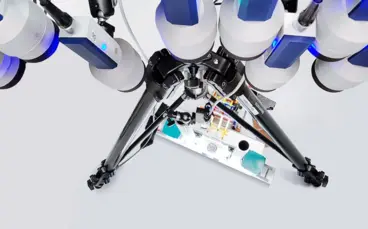

VibroScan QTec Xtra 3D三维扫描式激光测振仪

VibroScan QTec Xtra 3D采用非接触式全场测量技术,精度达到前所未有的高度。其突破性的多通道干涉测量技术,在光学灵敏度与抗干扰性能方面,为行业树立了全新标准。Xtra红外(短波红外,SWIR)激光,光学灵敏度极高,哪怕面对复杂棘手的工业表面,也能精准完成测量任务。同时,VibroScan QTec Xtra 3D 集成数据采集与信号发生器功能,带宽高达32MHz,极大提升了设备的便携性,为用户提供了便捷、高效的测量体验 。

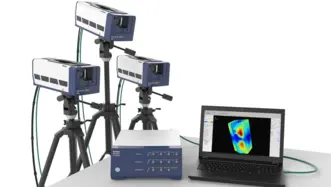

VibroScan QTec Xtra扫描式激光测振仪

VibroScan QTec Xtra 采用非接触式全场测量技术,精度达到前所未有的高度。其突破性的多通道干涉测量技术,在光学灵敏度与抗干扰性能方面,为行业树立了全新标准。Xtra红外(短波红外,SWIR)激光,光学灵敏度极高,哪怕面对复杂棘手的工业表面,也能精准完成测量任务。同时,VibroScan QTec Xtra 集成数据采集与信号发生器功能,带宽高达32MHz,极大提升了设备的便携性,为用户提供了便捷、高效的测量体验 。

测试服务和租赁

我们的工程服务覆盖领域极为广泛,无论是项目现场,还是专业实验室,都能精准对接需求。您可联系我们的 PolyXperts 专家团队,租赁前沿的激光测量设备,享受专为您的项目定制的个性化支持。我们经验丰富的应用工程师随时待命,热忱为您提供测量与测试服务。若您需要开展全面深入的研究,RoboVib® 结构测试站可供租赁,助力您的科研工作顺利推进。