Quality control (QC) for industrial manufacturing and process control using non-contact, optical measurement and testing solutions by Polytec: from testing acoustic and dynamic properties over surface characterization, length and speed measurement in the manufacturing process of continuous goods to spectral analysis for agriculture, food and chemicals. Polytec quality control solutions open up a realm of applications in quality control. Experience here, how our customers check tolerances, control process stability and secure quality.

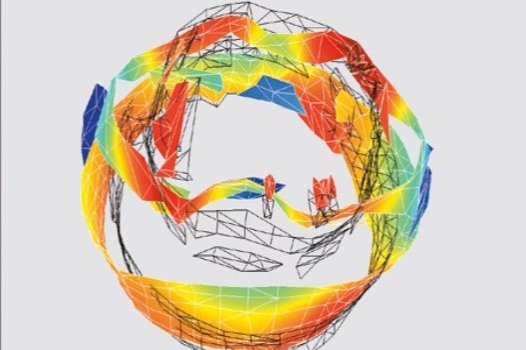

Quality control by optical 3D surface characterization

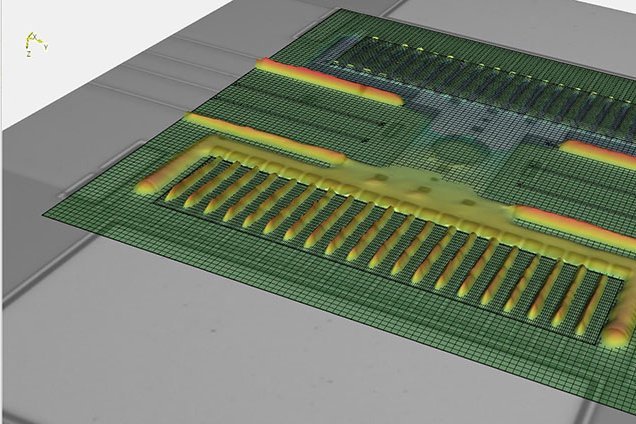

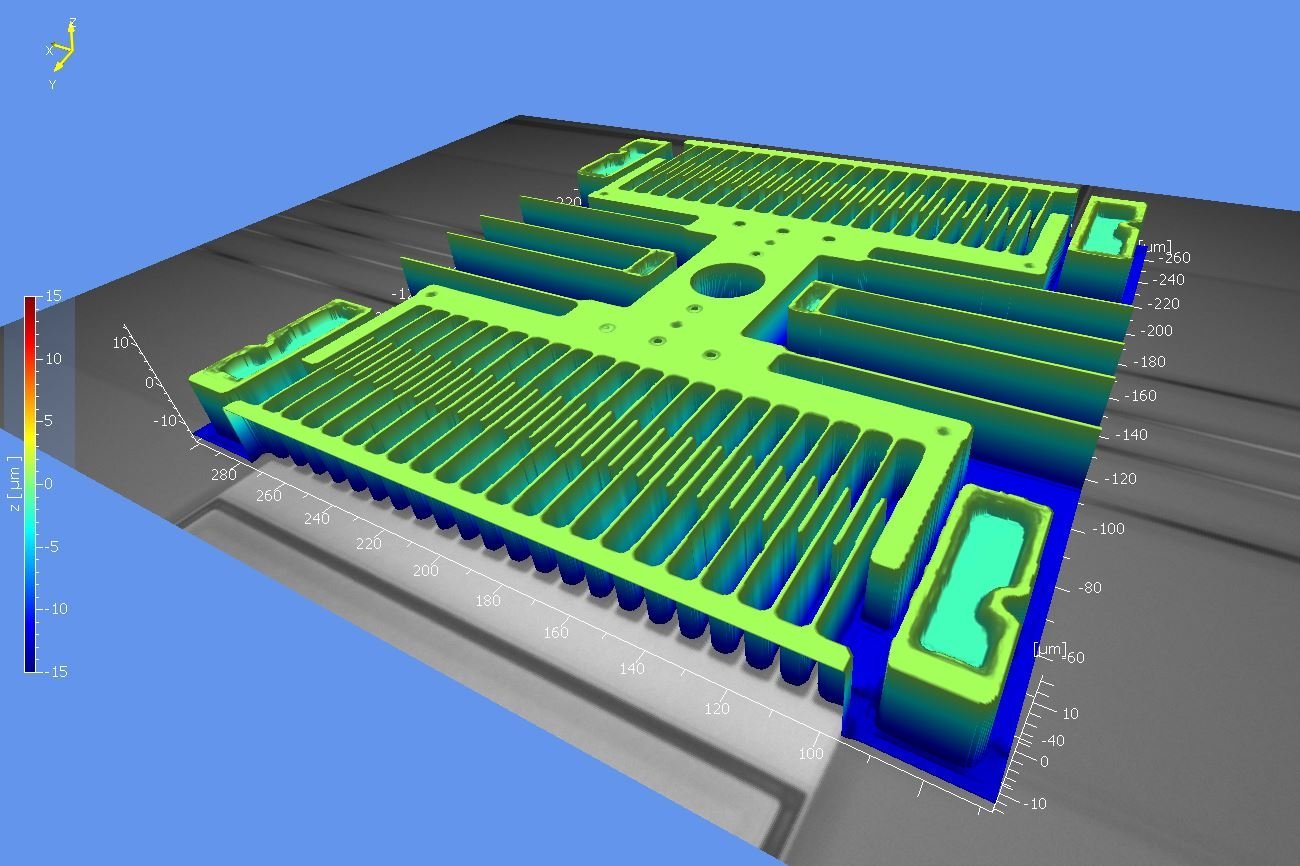

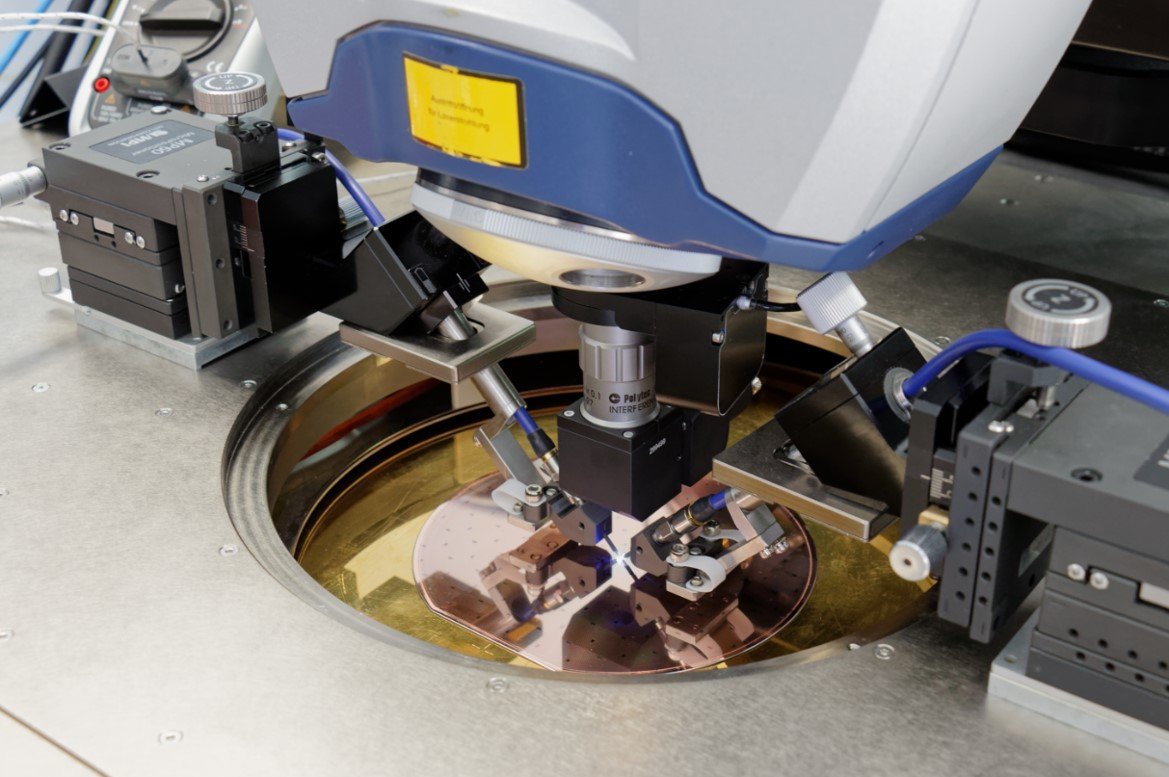

The QC Package for TopMap optical surface profilers are just an example of innovative solutions, offering smart quality control for industrial precision manufacturing and machining processes. Measure, visualize and evaluate surface parameters such as flatness, waviness, step height, parallelism, roughness or structural details close to or in the producion line and benefit from fast and efficient feedback on the machining process. Set up and manage different sample types in predefined measurement recipes and load the settings with barcode scanners for quick and easy operation at production level. Compare and synchronize measurement settings for worldwide standardization and rely on areal, non-contact and repeatable topography measurements.

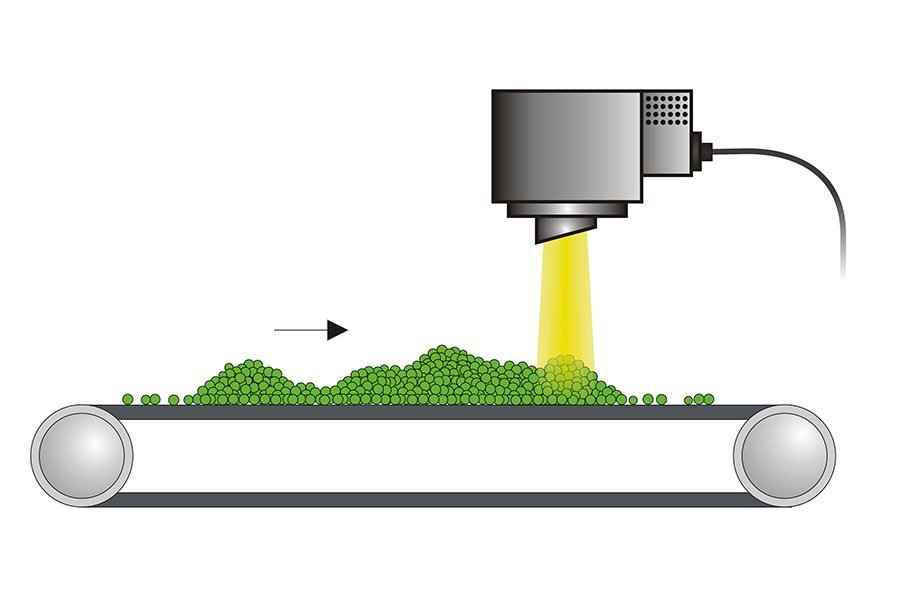

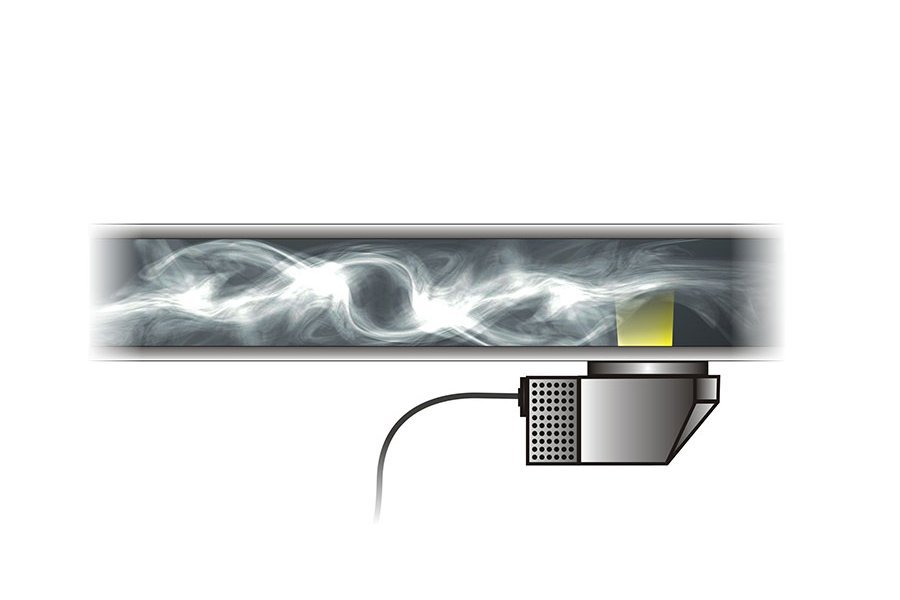

Non-destructive detection and quantification of physical and chemical characteristics

NIR Spectroscopy is well established and one of the most efficient Process Analytical Technology (PAT) tools, allowing non-destructive detection and quantification of physical and chemical characteristics of materials. Polytec provides NIR-Spectrometer-Systems for a wide range of routine analytical and/or industrial applications, from incoming material inspection through manufacturing processes and final product quality control.

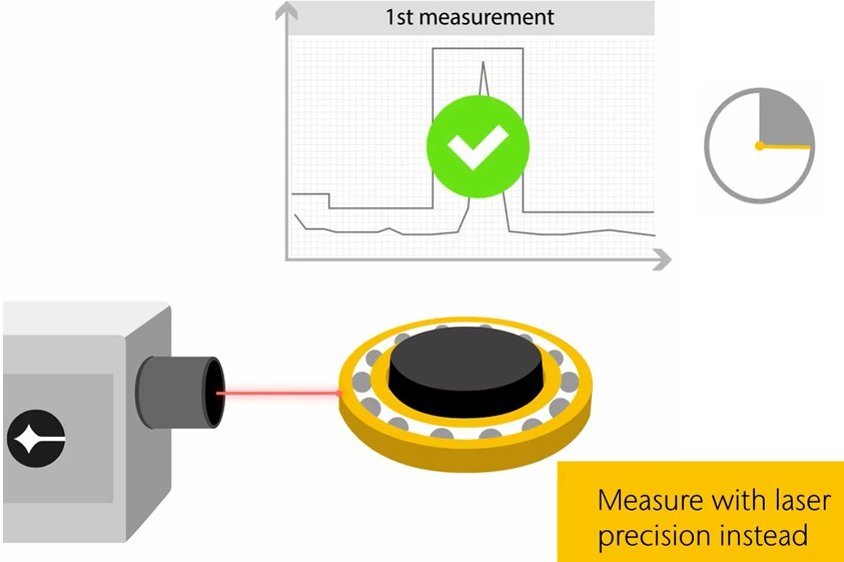

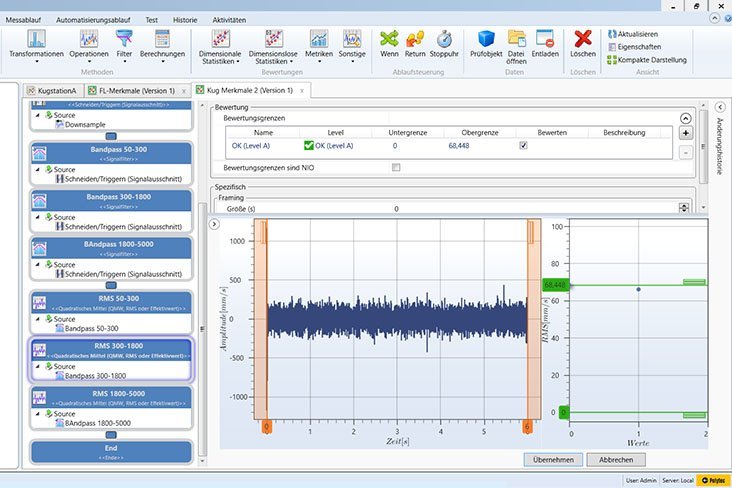

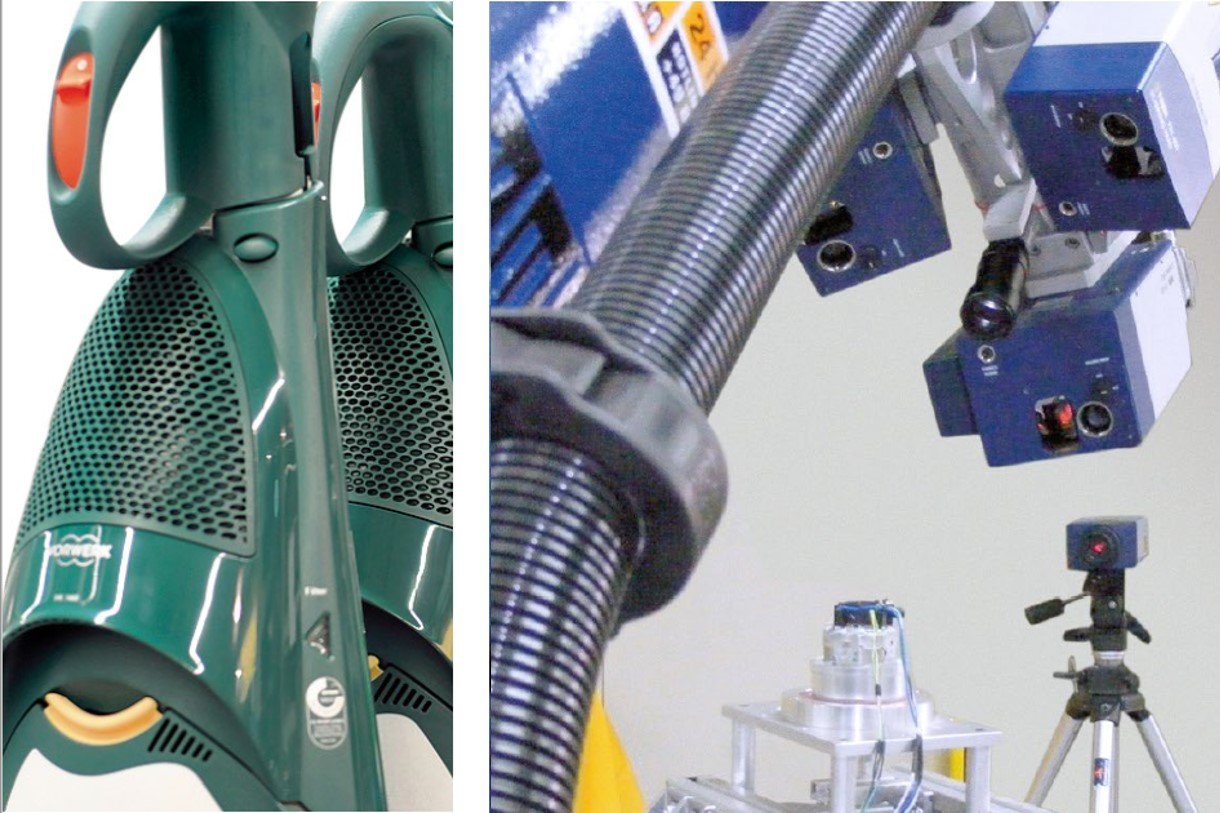

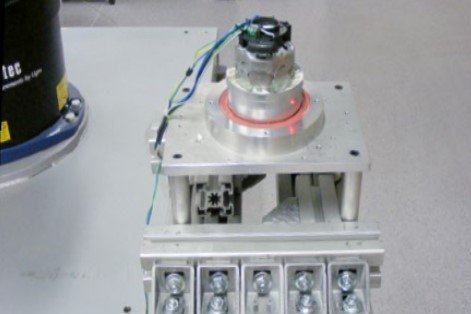

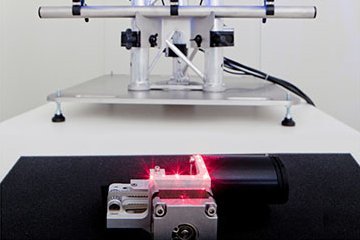

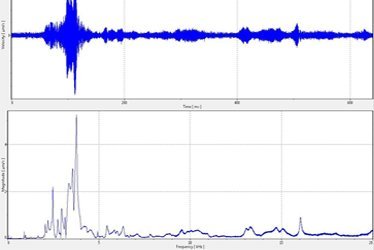

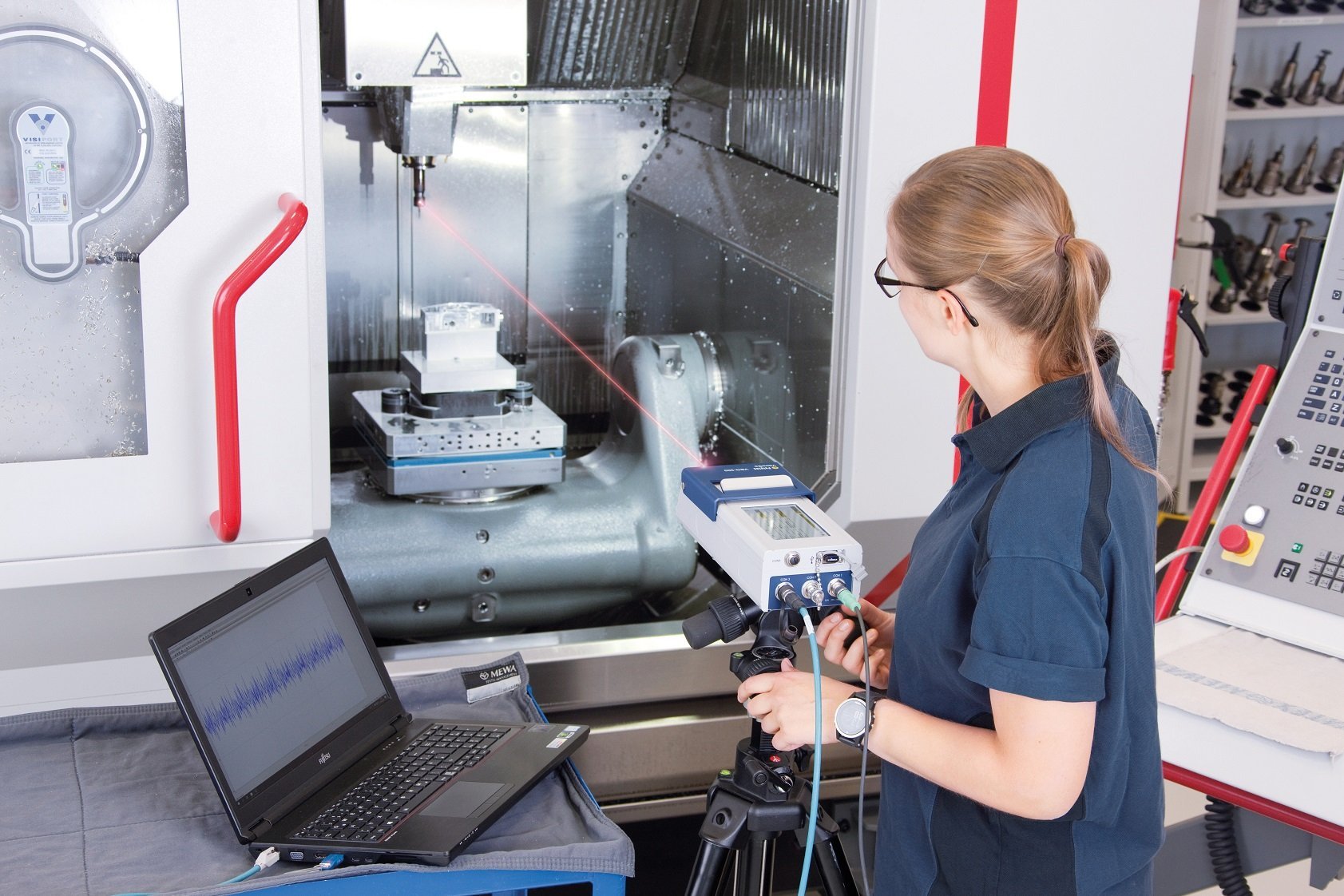

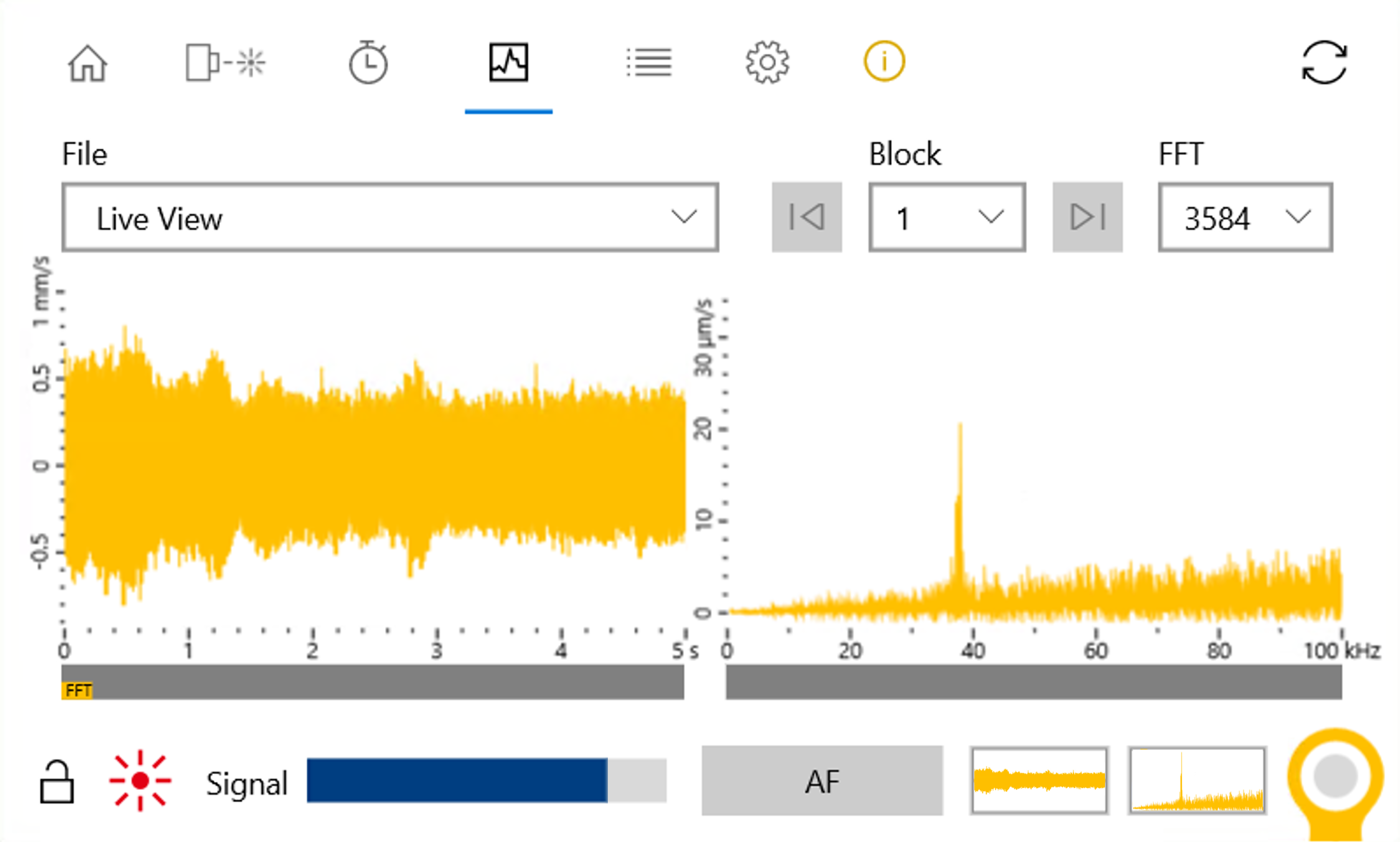

Putting accelerometers, microphones and laser vibrometers on the test stand