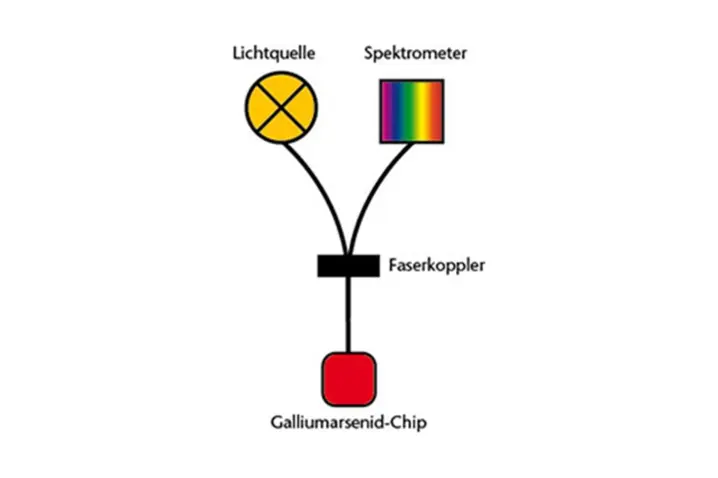

Single-Sensor at Fiber End

At the tip of an optical fiber, a GaAs crystal is mounted to use the long-proven method of temperature-dependent band-edge shift. White light is sent from the system to the crystal, and there the position of the current band edge—which shifts spectrally with temperature at about 0.4 nm/K—is altered. The light reflected back from the crystal end is analyzed with a spectrometer to determine temperature, based on factory calibration. The temperature measurement range is from –200 °C to +300 °C, with accuracies up to 0.1 °C.

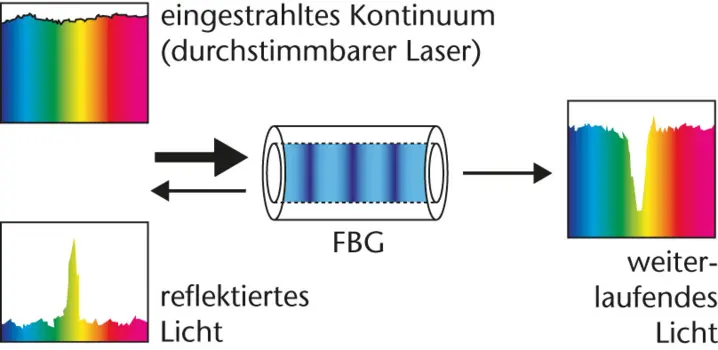

Distributed Measurement via Fiber Bragg Gratings (FBGs)

Fiber Bragg Gratings are created by exposing the fiber at specified positions to a periodic pattern of intense UV light. The refractive index of the fiber in those locations is “modulated.” In this way, sensors are “written” into a standard glass fiber at arbitrary positions. The grating reflects light in a narrow wavelength range which shifts when temperature or strain change. Several hundred FBGs can be written into a single fiber and queried simultaneously with one system. This technology allows monitoring of temperature, strain, and also acceleration or tilt in large structures, for example in design validation of new constructions or structural health monitoring of buildings. Temperature range: –50 to +300 °C (with special fibers even up to +800 °C), with achievable accuracy up to 0.1 °C and spatial resolution around one millimeter.

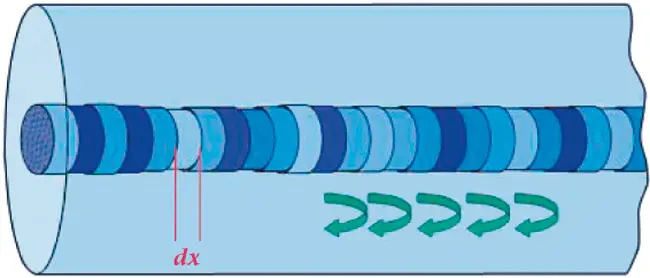

Distributed Measurement via Rayleigh Scattering

By augmenting an Optical Backscatter Reflectometer (e.g. Luna OBR 4400) with a sensing option, one obtains a highly flexible, high-resolution system suitable for distributed temperature or strain measurement along an optical fiber. The OBR is capable of detecting small refractive index fluctuations via Rayleigh scattering and localizing frequency shifts in the reflected light that are caused by changes in the fiber due to temperature or strain. Because this works with a variety of optical fibers, many types of sensors are possible.

Polytec Magazine

How fiber-optic temperature measurement helps develop Power-to-X technologies for the energy transition

Fiber-optic systems measure temperatures across fields, excelling where many sensors, compact size, and low thermal mass are needed—one 150 µm fiber can replace hundreds of sensors.

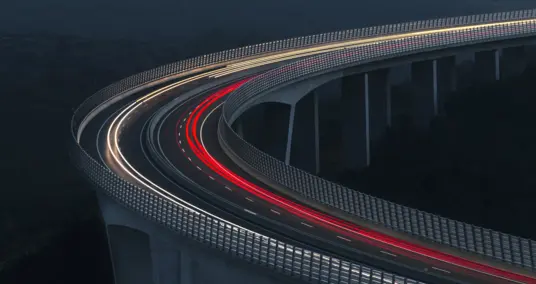

Continuous fiber optic strain measurement

Some bridges in Germany are aging and not designed for today’s increasing traffic loads. Authorities must now find cost-effective solutions to manage these existing structures.

Distributed fiber-optic temperature and strain measurement with extremely high spatial resolution

Sampling of the Rayleigh scattering along a length of optical fiber allows the realization of a distributed sensor system where every point along the fiber acts as a sensor. This novel method allows ...

Fiber Bragg Grating Sensors in Practice

Fiber-optic sensors are used in wind turbines not only for monitoring but also for control, for example, to adjust the rotor blades based on load measurements of the blades.

Distributed Fiber-Optic Sensing for Geotechnical Monitoring

Stones, blocks, steel, cement, concrete, and mortar—combined with large, heavy, clumsy, and noisy construction machinery—hardly make an ideal environment for a fragile glass fiber.

Fiber-Optic Temperature Measurement in Chemical Process Engineering

Conventional measurement methods quickly reach their limits when electromagnetic immunity, high measurement density, or chemically aggressive environments are required

Fiber-optic sensing in basic research

Friction clutches are used in millions of automobiles to transfer the engine’s torque to the drivetrain. However, the physical processes involved in frictional power transmission are still not completely u…

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters — get in touch with us today.