非接触式检测密封性能

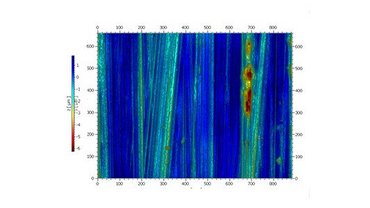

在各类工业连接中,密封表面的质量优劣直接关乎连接的长期防泄漏性能,堪称保障系统稳定运行的关键因素。为实现理想的防泄漏效果,必须极为精准地界定密封表面的几何特性,以此确保 “无泄漏” 这一核心功能的达成。一旦密封接触面的形状偏差超出既定公差范围,泄漏问题便极易出现,进而影响整个系统的正常运转。

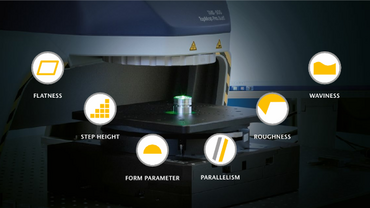

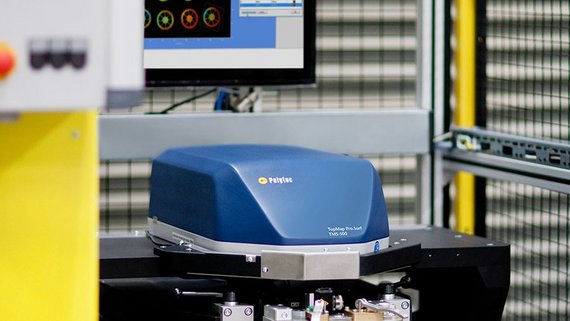

Polytec 的表面测量系统为解决这一难题提供了有效途径。借助该系统,企业不仅能够在实验室环境下对密封性能展开深入分析,更可将其无缝融入生产流程,实现生产过程中的实时检测。得益于先进的非接触式测量技术,在检测过程中,密封表面的原始形状和完整性得以完美保留,同时测量结果具备高度重复性,可随时按需复现。Polytec 系统操作便捷,分析流程高效迅速,能够极大地提升密封性能检测的效率与准确性,为企业产品质量管控与生产流程优化提供坚实保障 。

Polytec 杂志

适配严苛生产周期的表面检测方案

在各类生产作业中,当表面检测环节必须严格遵循紧凑的生产周期时,Polytec 表面测量系统便能充分展现其卓越性能,发挥出最大效能。这一应用场景在汽车行业极为普遍,例如在涉及喷射系统、压电共轨系统、压缩机的生产流程,以及发动机研发的整体过程中,Polytec 系统都能精准适配,助力企业在规定时间内高效完成表面检测任务,有力保障生产进度的顺利推进 。

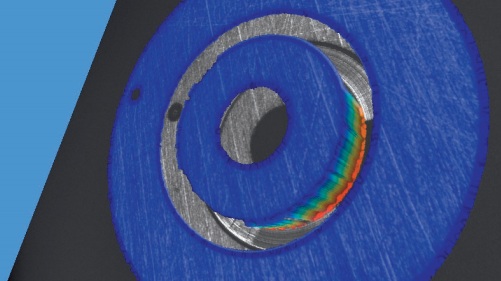

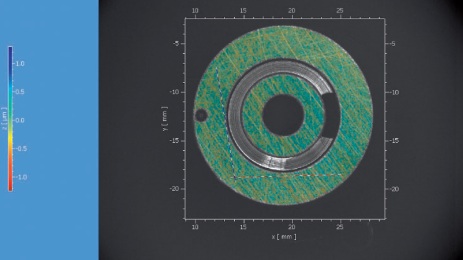

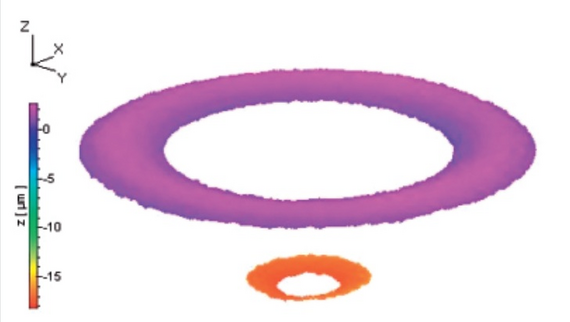

压电喷油器部件的面域形貌精准测量

压电喷油器作为汽车发动机的核心部件,其性能优劣对发动机的整体表现起着关键作用。在本应用场景中,需在大约 5 s的极短周期内,对压电喷油器的两个独立表面进行三维轮廓的精确记录。

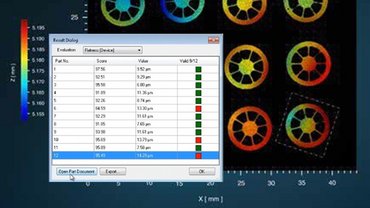

具体而言,喷油阀表面的光滑度、平行度以及间距等关键指标都需要进行细致评估。为确保测量结果的可靠性和一致性,测量的可重复性公差需严格控制在约 100 nm 的范围内。

为了准确获取上述关键参数,系统采用了精准分离采集的方式,对两个表面分别进行数据采集,从而为压电喷油器的性能评估和质量控制提供了精确、可靠的依据。