表面パラメータ

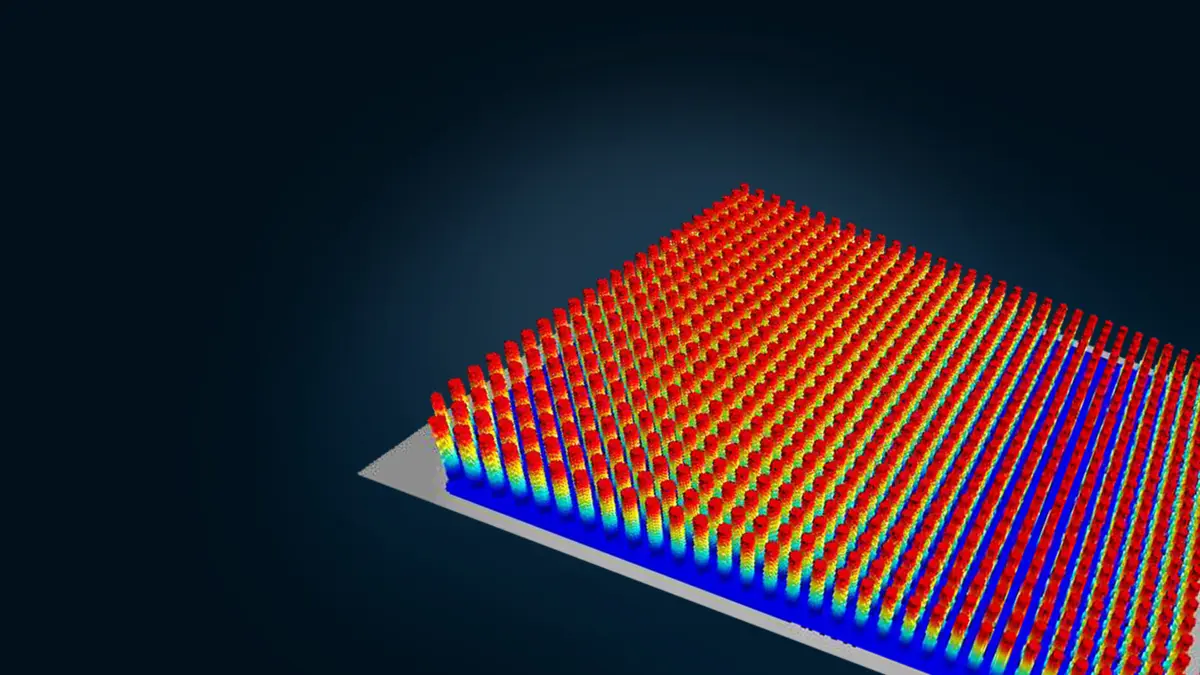

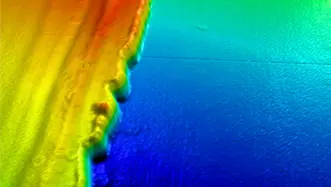

ワークピースの機械設計では、粗さやリップルなどの定義されたパラメータの仕様が含まれていることがよくあります。ポリテックの白色干渉計 非接触表面粗さ・形状測定機は、接触式の測定方法では長い時間を要する3Dプロファイル全体をわずか数秒で取得します。このようなパラメータ(例えば、接触面積の割合や周波数分布など)は、迅速かつ容易に決定することができます。粗さは非接触で測定することもできますが、その値は、図面の寸法や規格が参照する接触式測定の結果とは異なる場合があります。

しかし、ポリテックの白色干渉計を校正するための新しいガイドラインにより、ユーザは測定値が校正基準にまで遡ることができることを保証されます。非接触測定では、粗さのパラメータも利用できます。例えば、ダイナミックシールの表面が粗すぎて摩擦損失が大きくなるのか、それとも滑らかすぎて接着力が過剰になってしまうのかを判断するだけで十分な場合もあります。

表面パラメータとテクスチャ測定

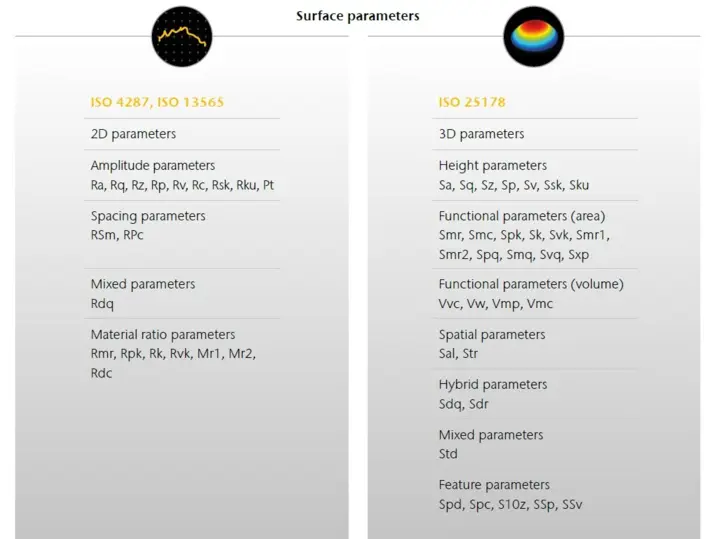

表面パラメータのISO規格一覧

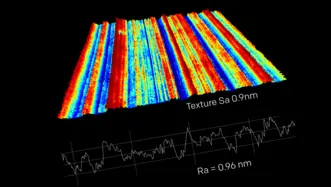

数多くの表面パラメータの数学的記述は、様々な国際規格に見られる。実用面では、2次元パラメータに関するISO 4287およびISO 13565、ならびに面全体表面粗さに関するISO 25178が特に重要である。これらの規格は、一般的に使用されるテクスチャパラメータを定義し記述している。

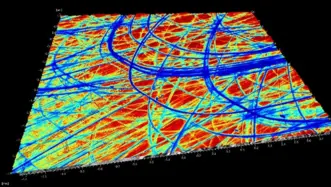

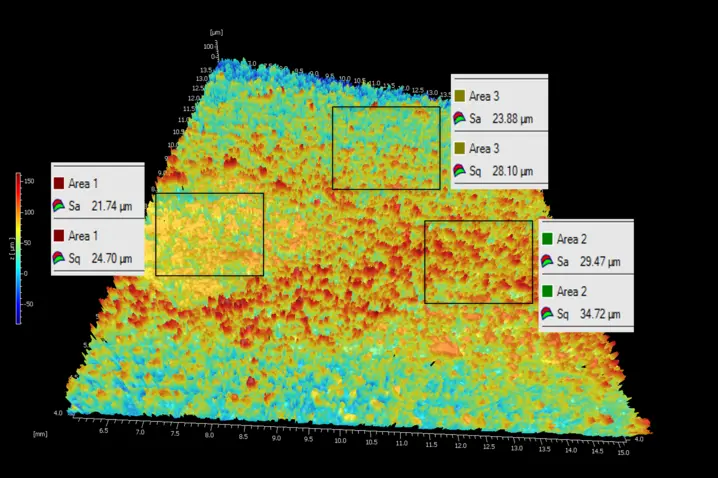

プロファイル基準から得られる多数のパラメータについては、公表された基準において同等の面積パラメータを見出すことができる。さらに、三次元性による追加的利点として、面積地形評価が提供される。

実務で頻繁に使用される振幅または高さの表面パラメータは、ほとんどが面積評価に拡張された。 地形評価における面積評価は、測定位置に対する感度がプロファイルベースの評価よりも低いため、特に不均一で欠陥のある表面において、より信頼性の高い測定結果を提供する利点がある。しかし、表面パラメータ群全体に共通する課題として、異なる種類の表面間の機能的差異を表現できない点が挙げられる。これは、製造方法や設計が異なる表面であっても、表面パラメータに関しては同じ結果を示す可能性があることを意味する。

当社の表面計測ソリューション

マイクロプロファイラー

Micro.View systems are optimized for ultra-high-resolution measurements in the sub-nanometer range. With focused optics and high vertical resolution they enable detailed analysis of microstructures, surface finish and material distribution where even the smallest deviations matter.

マクロプロファイラ

Pro.Surf は広範囲をスキャンし、形状と平坦性をより迅速に測定します。Z 範囲の広いテレセントリック光学系は、高い段差や穴などの深い部分も測定可能です。最大の視野と True Stitching 機能により、大きな試験片、トレイ、または複数の部品を 1 回で測定します。Pro.Surf+ は、粗さ評価機能を追加して可能性をさらに広げます。

Metro.Lab

Metro.Lab is a compact, wide-area bench-top surface profiler. It combines high measurement performance with a small footprint — ideal for space- or budget-conscious applications that still require reliable 3D surface data.

自信を持って最適な表面プロファイラーをお選びください——「購入前に試用」という当社のアプローチのメリットを享受いただけます。

ご要望について専門家とご相談ください

まずは部品仕様、公差、ワークフローについて簡単に話し合いましょう。必要に応じて、実現可能性調査、PolyMeasure(契約測定)、またはPolyRentトライアルをオプションの次のステップとして追加することも可能です。