ISO 21920 - what the standard means for roughness measurement

ISO 21920 is the new standard for mechanical engineering, design and roughness specifications. Learn more about the motivation for this renewed ISO standard, what does it mean for your daily roughness and form measurements, what do the three parts of the ISO 21920 stand for and how to implement it in quality control – Polytec guides you!

The ISO 21920 represents a central set of rules for roughness profiling, replacing and modernizing some of the standards that had been generated decades ago.

Surface roughness & finish depend on the perspective

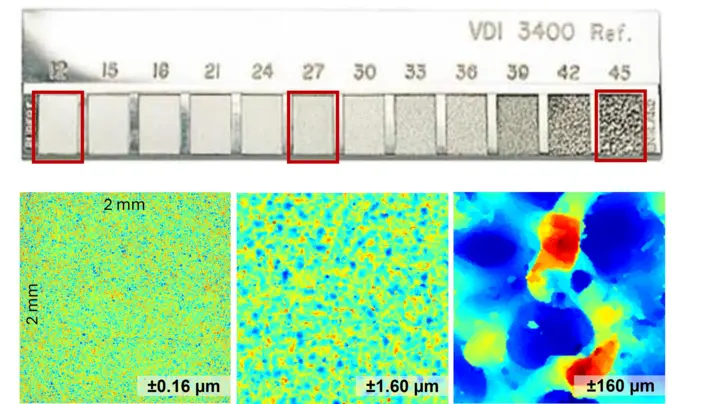

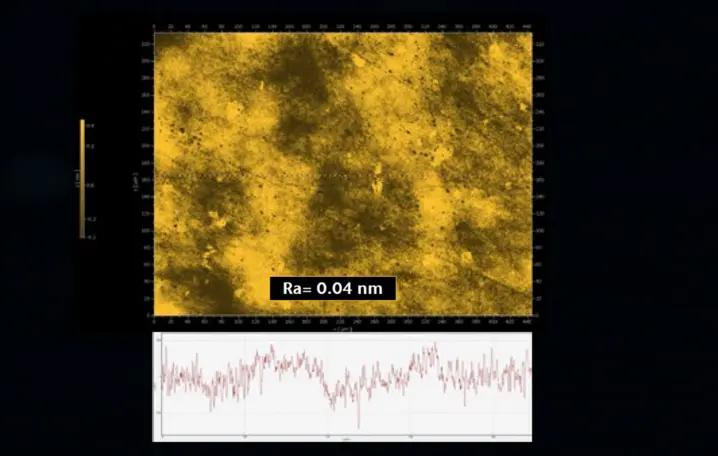

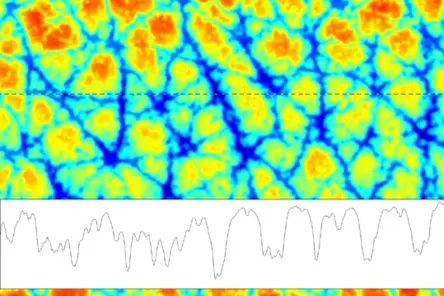

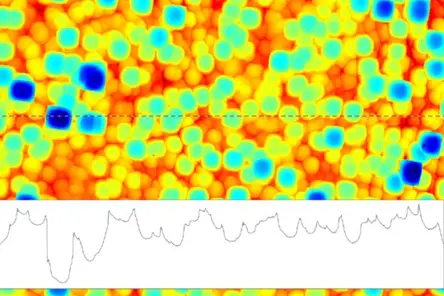

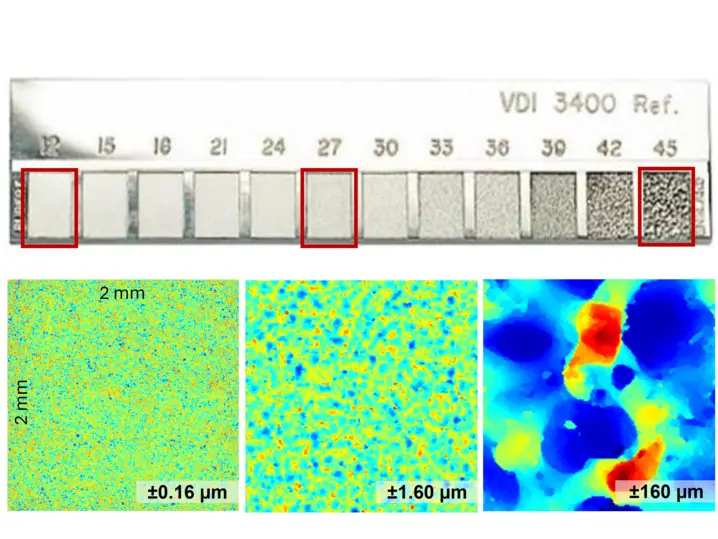

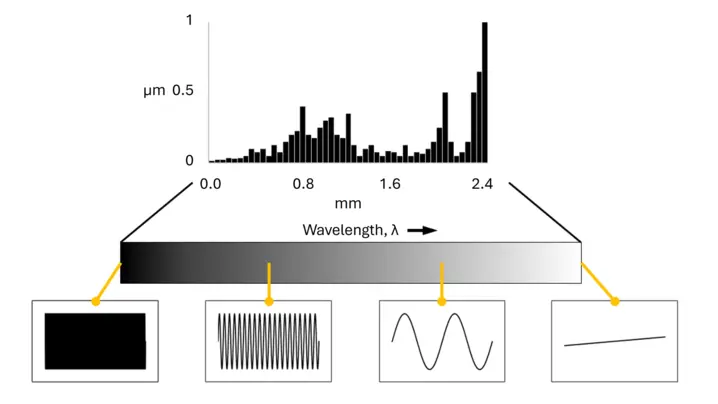

Besides complying with geometric specifications in machining (e.g. exact measures of a component), its shape and position tolerances (e.g. the position of a hole), the quality of the surface plays an essential role for its functionality and longtime performance, whether in traditional mechanical engineering or electronics, semicon or optical components. Depending on the application, surface roughness requirements vary by several orders of magnitude, spanning a wide range from < 1 nanometer [nm] to several micrometers [µm].

Download the exclusive guide on ISO 21920

Read the full exclusive paper (login) about the relevance of technical drawings (replacing ISO 1302), why ISO 21920 is more than just Ra (replacing ISO 4287 and ISO 13565-2/ -3) and how to achieve valid measurement results (replacing ISO 4288).

The roughness concept – principles of ISO-21920

As shown in previous examples, "roughness" is an abstract term, possibly meaning different things for two different people depending on the perspective or expectations. Join or contact us for our roughness webinar explaining the basic concept of roughness in brief. This shall enable a common understanding.

ISO 21920 for uniform roughness specifications

One of the goals of the ISO 21920 standardization is preventing ambiguities in the interpretation of roughness specifications, thus enabling clear communication e.g. between design department and quality control. The three-part standard ISO 21920 specifies :

- how to enter drawings

- how parameters are calculated

- and how to measure them.

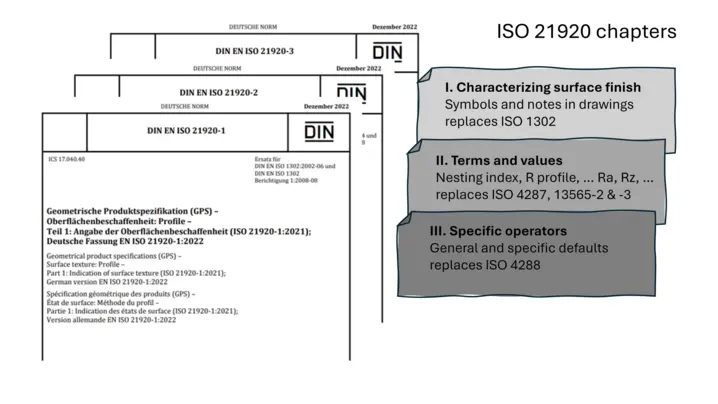

Structure of ISO 21920 standard for profiling

ISO 21920 is a profiling standard, consisting of three parts

- the specification of the surface finish (replaces ISO 1302)

- the terms and parameters like nesting index, R-profile, Ra - Rz... (replaces ISO 4238, 13565-2 and -3)

- the specification operators (replaces ISO 4288).

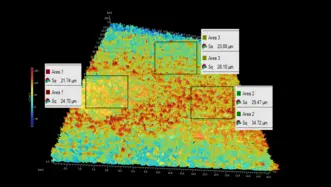

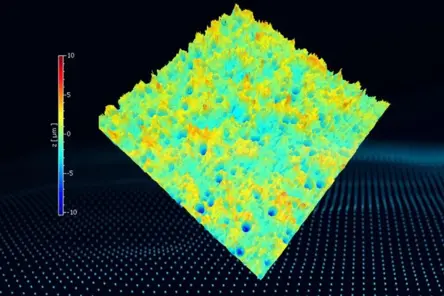

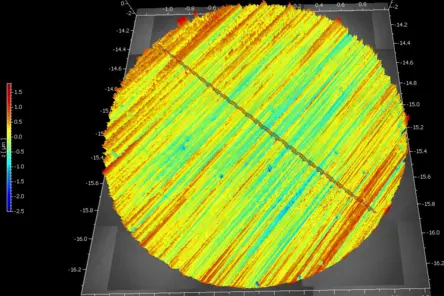

Some terms and parameters were based on the surface standard ISO 25178, which was first published in 2012. In many cases, surface roughness measurement has decisive advantages over profile-based roughness measurement. The optical and areal measurement of surface roughness is not only optical and contact-free, it also provides a complete image of the surface in a click.

This is particularly beneficial, if one cannot assure that specific profiles measured are indeed representative for the whole workpiece surface.

How to measure surface roughness using Polytec white-light interferometers

WLI profilers for ISO-ready surface measurement

Micro.View

TopMap Micro.View® is an easy to use optical profiler in a compact table-top setup. Choose Micro.View® as the cost-effective inspection tool for examining precision-engineered surfaces down to the sub-nm range, for inspecting roughness, microstructures and more surface details.

Micro.View+

Advanced microscope-based surface profiler with automation and color imaging. Micro.View+ enables repeatable, operator-independent roughness and texture analysis—ready for lab and production use.

Pro.Surf+

Multi-sensor optical profiler combining large-area form measurement with integrated roughness analysis. Pro.Surf+ delivers fast, traceable form and roughness results in one production-ready system.

Choose the right surface profiler with confidence—benefit from our "try before buy" approach.

Related articles and downloads

Downloads

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.