Non-contact vibration measurement

Polytec manufactures a wide range of laser vibrometers that are the acknowledged gold-standard for non-contact vibration measurement. No matter what your measurement needs are in research, development and production or even for long-term monitoring, there is a Polytec system that provides the answer. Laser-Doppler vibrometers analyze samples of different size, from entire car bodies, large aerospace parts over engines and actuators to micron-sized MEMS or biomedical specimen and components.

Numerous research applications in mechanical and civil engineering, biology and medicine benefit from testing and measuring with non-contact vibrometry. Polytec laser vibrometers easily master challenging conditions like measuring on hot surfaces, on rotating parts, and characterize complex and sensitive structures even in the ultrasonic frequency range. Polytec laser vibration sensors help to solve your measurement task fast and precisely.

No budget? Just measure.

Whether you need contract measurements, equipment rental, or leasing, our scalable services deliver precise data—without the overhead of major investments. Ideal for short-term projects, occasional use, or limited budgets.

With PolyFlex you get results without compromising timelines or budgets.

NEW

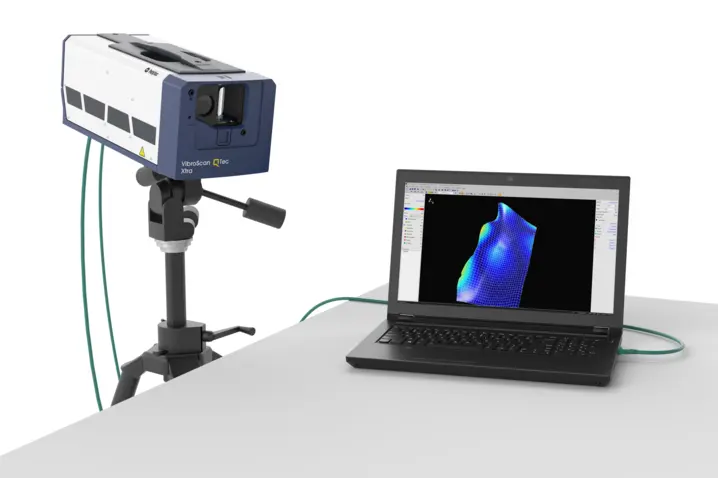

VibroScan QTec

The new standard for full-field vibration measurement

With the new VibroScan QTec we push reliability, flexibility and speed to the next level. With IR or HeNe even the toughest measurement tasks can be mastered in your product development, quality assurance or research projects.

Measure in 1D or 3D up to 10 times faster and with increased signal quality thanks to the patented QTec® technology.

Experience the new VibroScan QTec in a video presentation

With the new VibroScan QTec, we are taking reliability, flexibility and speed in non-contact vibration measurement to a whole new level. In this webinar recording, our expert Jörg Sauer takes you into the world of groundbreaking QTec technology and the new VibroScan QTec for your modal analysis, acoustic and NVH measurements, operational vibration analysis and product development.

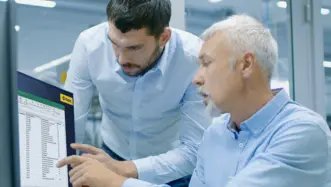

Get in touch with our experts

Get in touch with our experts

Do you have questions about laser vibrometry?

New QTec® multipath laser interferometry

The new QTec vibrometers make vibration measurements so much faster, better and more efficient. When measuring vibrations with the patented QTec® multipath interferometry, the SNR is optimized on all technical surfaces. See in the video, how QTec® interferometry assures reliable measurements on all surfaces.

Laser vibrometry focusing on the small details

Characterize small and delicate structures in a non-contact way. Analyze vibration, acoustics and dynamics. Measure biomedical samples, electronics components and microstructures like MEMS by light, without mass-loading, and from DC up to the GHz range on a large bandwidth. Laser vibrometers focus on the small details, measuring deflection shapes for model validation. They assess the frequency response and determine resonance frequency, impulse response and Q factor. No matter how big or small – Polytec vibrometers measure it!

Polytec Magazine

Explore professional articles, research insights, and technology trends, and experience measurement technology from every angle to measure what matters.

Gravity in the Lab

Anyone wanting to measure G needs an experimental setup capable of the seemingly impossible—detecting movements smaller than the diameter of an atom, triggered by pure “action at a distance.” The team arou…

Decrypting the machine physics with the 3D laser Doppler vibrometer

Feeding technology is a key process in automated production. In order to develop feeding systems using simulation, the machine’s physics must be known. As a specialist in feeding technology, the RNA Group …

Laser-Doppler-Vibrometer set standards in the development of electric drives

Electric machines are increasingly being used as the primary drive technology in vehicles. The acoustic behavior of the drive is a key factor in the perceived quality of electric vehicles. Numerical method…

Vibration measurement tasks

Measure remotely on red-hot surfaces, on rotating components, analyze high-frequency ultrasonic tools and fully understand the dynamic behaviour of the most complex and delicate structures in 3D. See how Polytec's vibration measurement technology helps to reveal the true vibration, acoustics and dynamics of vibrating structures.

Products

Laser Doppler vibrometers from Polytec are precision vibration sensors and comprehensive optical testing solutions representing the globally established gold standard for non-contact vibration analysis.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters — get in touch with us today.

Measurement, rental, calibration and more services

Our engineering services cover a wide range of applications, either onsite or in our laboratories. Contact us for planning your system calibration or rent cutting edge laser measurement equipment. Our experienced application engineers are pleased to help, measure and test for you. For comprehensive studies, rent the RoboVib® structural test station!

Environmental commitment according to ISO 14001

We at Polytec proudly announce our certification according to both ISO 14001 and ISO 9001. These certifications reflect our strong commitment to quality and to our environmental responsibility—cornerstone of our continuous improvement process. Thanks to our team and external partners for their dedicated support!

Accredited to ISO/IEC 17025:2017

Polytec Inc.'s ISO/IEC 17025:2017 accreditation reflects our commitment to excellence in testing and calibration services. Compliance with international standards ensures alignment with global best practices, allowing for widespread acceptance of test results and minimizing the need for re-testing.

Laser vibrometry for measuring vibration, acoustics and dynamics

Laser vibrometry from Polytec defines the established gold standard in optical vibration measurement. Poltyec customers benefit from a comprehensive range of testing solutions for almost every analysis and testing task in research, product development, production testing and condition monitoring with regard to vibration, acoustics and dynamics. Laser Doppler vibrometers are optical precision tools for the non-contact investigation of the dynamical or acoustic properties of test object.

What is the advantage of laser vibrometry?

Laser vibrometry is a non-contact, optical measurement method that is particularly suitable for measuring vibration processes, where even the slightest contact on the test specimen causes influence on the behavior, surface or mechanical properties during testing.

Laser vibrometry takes over where alternative measurement methods such as accelerometers reach limits. Contacting methods sometimes require complex cabling and installation effort or might even not be applicable. Laser vibrometry detects mechanical vibrations and structure-borne noise over a wide frequency range, reaching from the acoustic to the GHz regime, while showing a very linear phase characteristic with impressive amplitude accuracy.

Especially for the measurement of air and fluid vibrations or vibrations of very delicate, light or biological samples, only non-contact laser vibrometry is suitable.

How does laser vibrometry work?

The basis of laser Doppler vibrometers is the Doppler effect. When light is scattered back by a moving object, its frequency changes, too.

The highly accurate laser interferometer measures even the smallest frequency changes. The laser beam is split into a reference and a measurement beam, with the reference beam pointing directly to the photodetector. The measurement beam is directed to the target, where it is scattered by the vibrating surface. Depending on the velocity and deflection of the measuring object, the backscattered light receives a change in frequency and phase and thus contains the entire information about its motion and vector. The two beams are superimposed on the photodetector, resulting in a motion-dependent modulation of the detector signal. From this, the vibration velocity and deflection of the measured object are determined electronically.

Where to use laser vibrometry?

In industrial research and development, laser vibrometry is used to examine objects of very different sizes - from entire car bodies, aircraft parts and engines to tiny microsystems responsible for making our mobile devices smart and classically in hard disk components. In addition, there endless research applications in biology, medicine, technical acoustics and many other fields. Laser Doppler vibrometers are also used for industrial quality assurance like in end-of-line testing or for condition monitoring. Even on red-hot objects, rotating components, ultrasonic tools and complex or sensitive structures, laser vibrometry is the key for measuring, analyzing and improving technology and production.