Non-contact measurement of speed and length for production control

In the production of strip and sheet material, continuous material as well as piece goods, for example in steel or paper mills, knowing the exact strip length and current process speed is essential for keeping costs low and optimizing quality and yield. LSV (Laser Surface Velocimeters) from Polytec are optical sensors for the precise in-line monitoring of length and speed in production processes. The laser sensors measure in a non-contact way, providing precicion measurements on any material - no contact, no slippage, no wear. Avoiding any influence on the measured material, these non-contact encoders works reliably even in harsh production environments, in cold and hot temperatures. The latest generation ProSpeed® LSV length and speed sensors impress with maximum precision and reliability, featuring a 3-year warranty and custom service options tailored to your process control.

Products

ProSpeed LSV-2100

The ProSpeed® LSV-2100 optical sensor determines the direction of motion and standstill conditions with laser precision. It measures reliably even under harsh production conditions with large working distances up to 3 m on basically any surface and material.

ProSpeed LSV-1100

The ProSpeed® LSV-1100 optical sensor measures in forward direction with laser precision. It measures reliably even under harsh production conditions with working distances up to 1.5 m on basically any surface and material.

Service & Support

Free 3-year warranty, outstanding service and reliable support: Our PolyXpert services range from on-site support to sensor integration, custom solutions, dedicated training, calibration or repair and our uncompromising sensor exchange program. Polytec sensors come along with a reliable partnership, know-how and trust!

Need more information?

Learn about our optical speed and length measurement solutions today.

Enhancing industrial processes with optical sensors

Efficient process control using ProSpeed® laser speed and length sensors

Climate change is one of the dominating challenges of modern society and industry. Even though steel is one of the worlds most recycled materials, the steel industry remains the largest industrial emitter of carbon dioxide. For a more sustainability and responsible manufacturing, ProSpeed® Laser Surface Velocimeters can assist in process control

Roling & mass flow control

Skin-pass degree measurement, roll gap determination for controlling the strip thickness: Controlling the mass flow means controlling the width of the roll gap so that the material thickness of the final product remains as constant as possible. ProSpeed® LSV laser-optical sensors help determine the thickness before the roll stand as well as the velocity before and after the roll stand, providing reliable inline measurement data for precise adjustments during the production process.

Continuous casting

High temperature resistance and repeatability are key for continuous casting lines. ProSpeed® LSV optical sensors enable reliable production process control, directly increasing the casting yield. Reducing the safety factor by just a few mm when cutting to length, the investment cost for optical sensors in casting lines amortize within ~one year. For hot and harsh conditions, the TPH Thermo-Protective Housing keeps a cool (sensor) head, with excellent cooling capacity up to 200 °C.

Typical industries for optical sensors

Related Articles & Downloads

Downloads

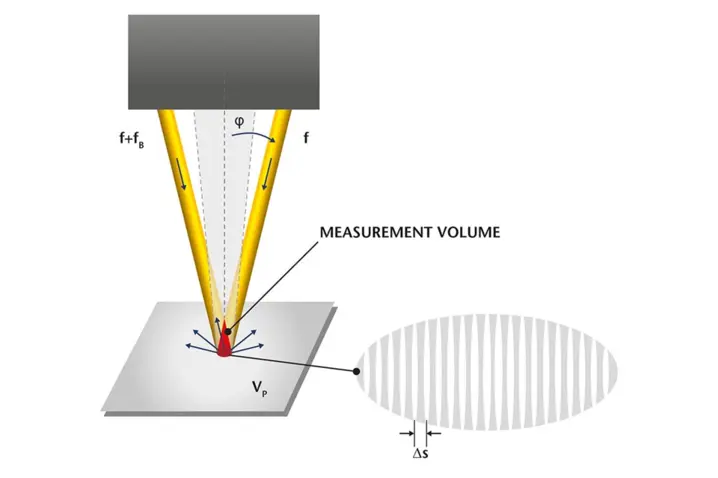

Laser Doppler velocimetry

Laser surface velocimeters work according to the Laser Doppler Principle and evaluate the laser light scattered back from a moving object or surface. Polytec’s LSVs are based on the very challenging and sophisticated heterodyne detection method.

Environmental commitment

We at Polytec proudly announce our certification acc. to both ISO 14001 and ISO 9001. These certifications reflect our strong commitment to quality and to our environmental responsibility—cornerstone of our continuous improvement process.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters—get in touch with us today.