表面粗さと形状の非接触同時測定

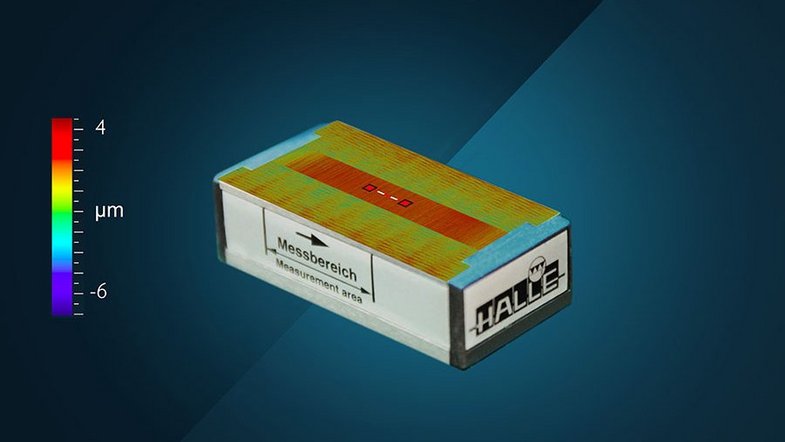

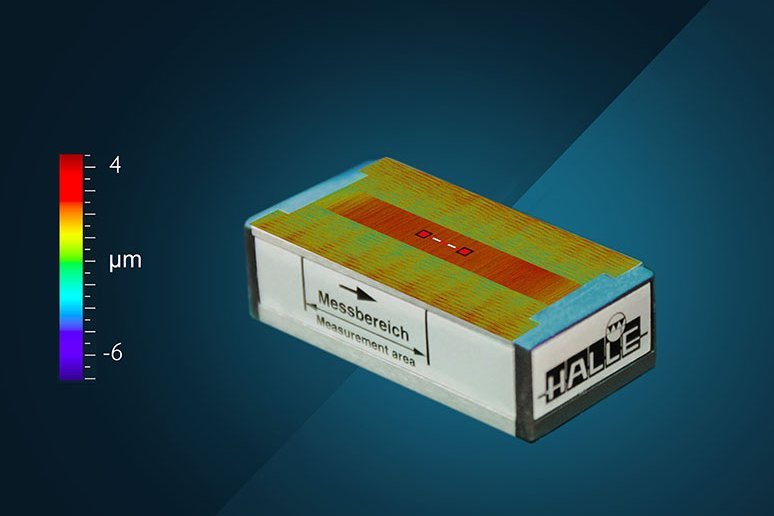

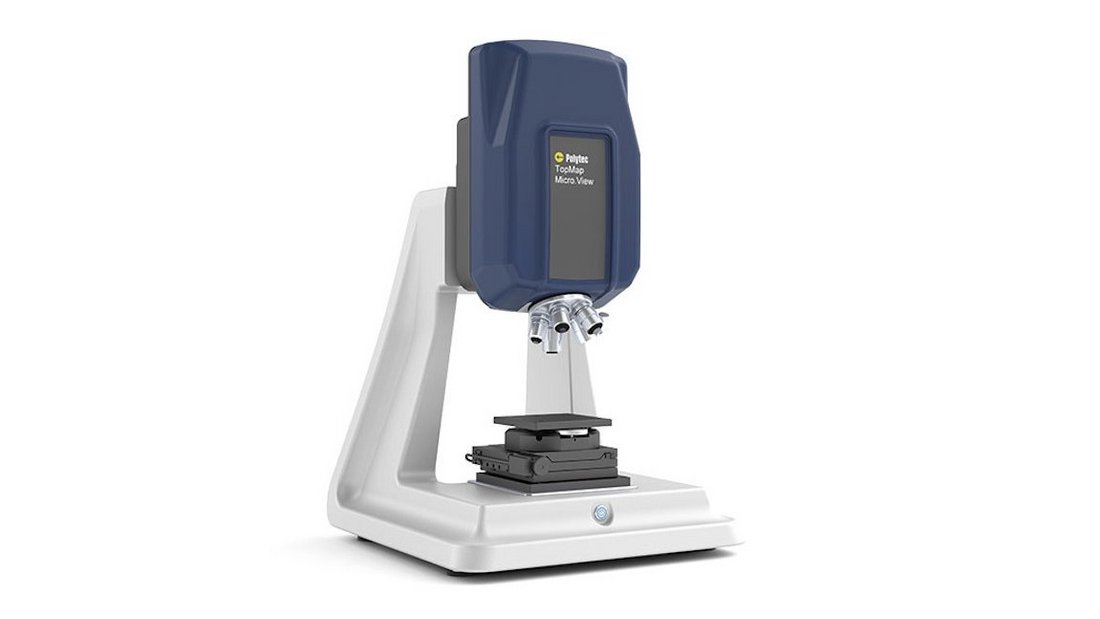

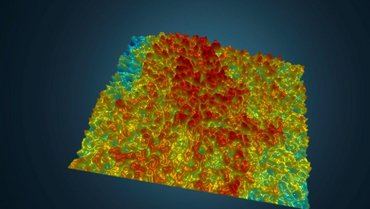

表面品質は、製品の機能性を保証するために非常に重要です。例えば、歯科治療用の金属製インプラントには、特に低い粗さが求められます。一方、多くの原材料は、その後の塗装やコーティングの工程で、特定のレベルの粗さが要求されます。アプリケーションによっては、形状偏差と粗さの情報を同時に必要とする場合もあります。ポリテックの TopMap 非接触表面粗さ・形状測定機では、ナノメートル分解能で形状偏差を測定し、広い測定視野と高い分解能で表面粗さを測定することができます。白色光干渉計を使用した面測定に加え、クロマティック共焦点センサによる粗さの測定も可能です。測定表面全体の特性を把握し、体積を計算し、形状偏差を正確に決定します。

表面粗さと形状の非接触同時測定を実現する製品

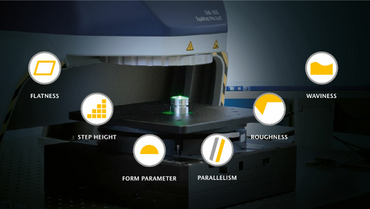

TopMap 非接触表面粗さ・形状測定機シリーズの TopMap Pro.Surf+についてご紹介します。TopMap Pro.Surf+は、広い範囲をスピーディーに測定し、高さや段差、平行度、粗さ、テクスチャなどのパラメータに関する面的な情報を3Dで正確に収集します。

表面粗さ、うねり、形状の違いとは?

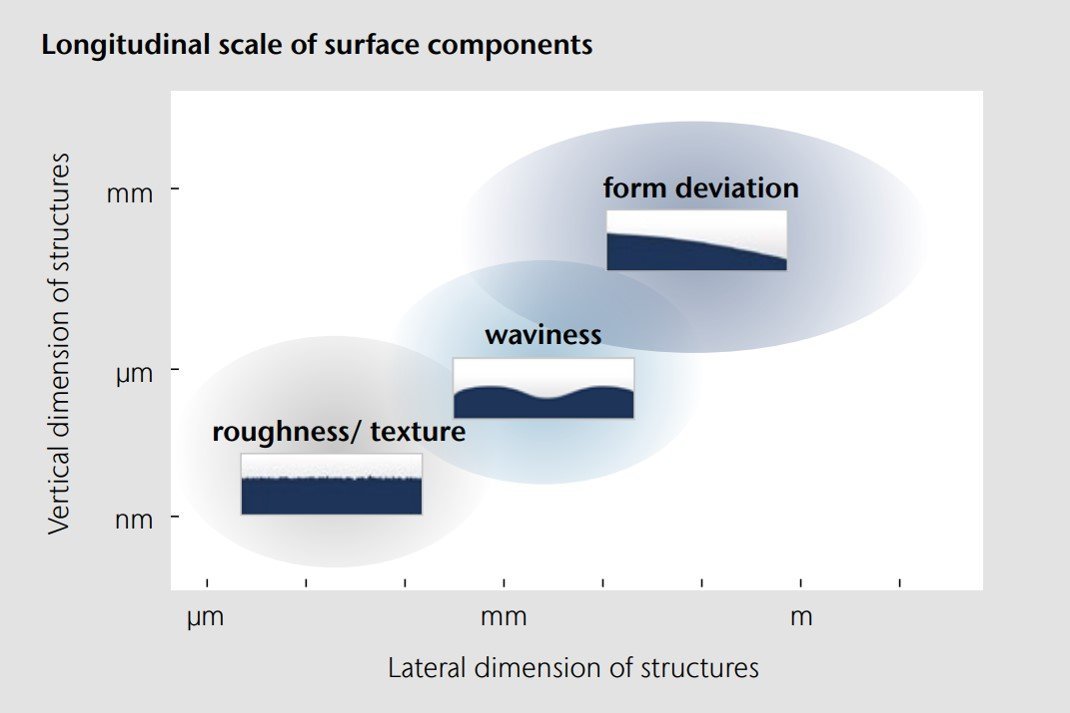

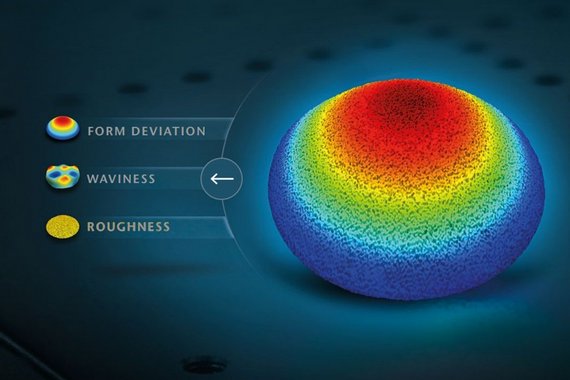

表面粗さ、うねり、形状は、表面性状の3つの主要な要素で、その発生原因によって分類されます。表面粗さは、どのような製造プロセスにも内在しており、エッジ形成や工具先端の凹凸の結果として、機械加工(例:切削工具、火花)によって残されるものです。うねりは、たわみ、振動、アンバランスな砥石、不規則な工具送り、びびり、または外的な影響などの要因から生じます。形状は、粗さやうねりとは関連しない表面性状であり、形状偏差を測定することで、正確な幾何学的特性を特徴づけます。

表面粗さ、うねり、形状の定義

表面粗さ、うねり、形状は、シャープに定義されるのではなく、互いに近くに定義されています。表面性状は、多数の波長の重ね合わせと表現することができ、表面成分内の形状(特に長波長)からうねりを経て短波長の粗さ成分へと滑らかに移行します。詳しくは、ホワイトペーパーをご覧ください。