Dear visitor, in order to be able to watch our videos please accept the cookies. All information about the usage of cookies can be found in our privacy policy

TopMap profilers: hardware, optics, software & service

Polytec offers complete optical surface metrology solutions for quality inspections of engineered surfaces and form evaluation – whether flatness or step-height on CNC-machined precision parts, warpage and form on smooth optics, or texture, finish or MEMS and microstructure analysis.

We build the most reliable white-light interferometers, backed by application service and know-how, 4 years of warranty and a lifetime free software updates.

Our profilers measure non-contact and promise precise and repeatable measurements. Benefit from the extraordinary large vertical range and high Z resolution, and the impressive Field-of-View (FOV) even allowing multi-sample measurements. Whether fast scanning of large samples or thorough texture and roughness analysis with sub-nm resolution – challenge the TopMap profilers and test for free!

Optical profilers

Optical profilers from Polytec are innovative, precise and non-contact measurement systems for characterizing the entire surface topography of a workpiece or a microstructure in 3D. With their large vertical range, nanometer resolution and the ability of areal measurement for large samples or multi-sample measurements in a single shot, these optical profilers are perfect for measurement laboratories or production testing needs.

Software & accessories

Learn more about our software. Our mission is to provide intuitive and efficient measurement systems. Based on this promise, we provide comprehensive measurement and analysis software for easy filtering and analysis of measured data. Use automated analysis features for routine inspections and benefit from the open software architecture for application-specific and user-configurable interfaces. Any more questions? Contact us!

Service & support

The range of Polytec measurement services allows anyone to characterize surfaces of precision engineered products using our engineering services and system rentals. That way, you can make use of the latest measuring technology without investment. We also offer training sessions and application support on-site. Contact our PolyXperts team with any questions!

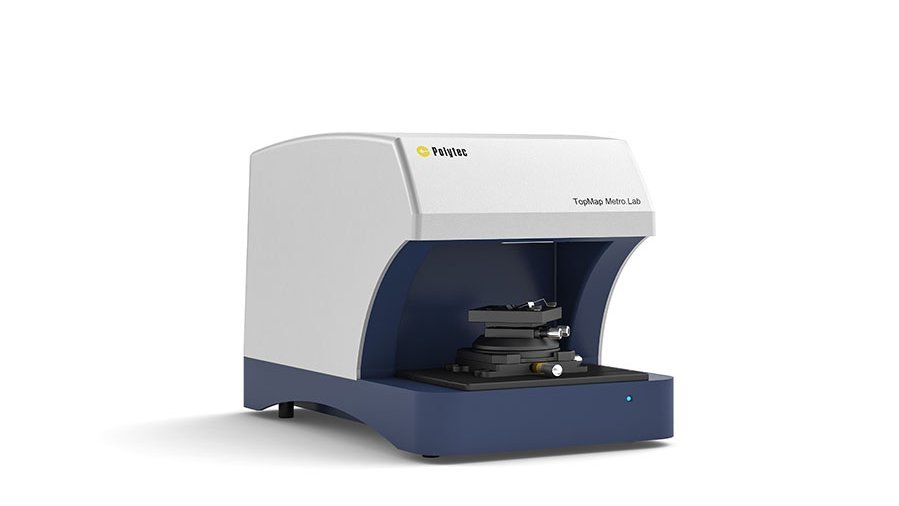

TopMap Metro.Lab

Start with areal surface and form characterization even with a smaller budget! TopMap Metro.Lab as complete and compact surface test station allows to examine large workpieces quickly, with reliable and repeatable results from shiny to rough surfaces.

TopMap Pro.Surf

Pro.Surf stands for fast and professional 3D surface characterization: Capturing 2 million measurement points within seconds make sure to see every detail. Pro.Surf masters challenging production workflows with short measuring times. The exceptionally large field-of-view (FOV) 33x44 mm captures big samples or even multiple samples in a single shot - while stiching expands to 230x220 mm with the large 70 mm Z range for enhanced flexibility.

TopMap Pro.Surf+

The multi-sensor profilometry system measures areal topography and form on an exceptionally large field-of-view (up to 230x220 mm) like common for Pro.Surf – while adding the chromatic-confocal sensor for complementary roughness line profile evaluation. Fast scanning, repeatable measurements for combined form & roughness characterization resolved in the nm range.

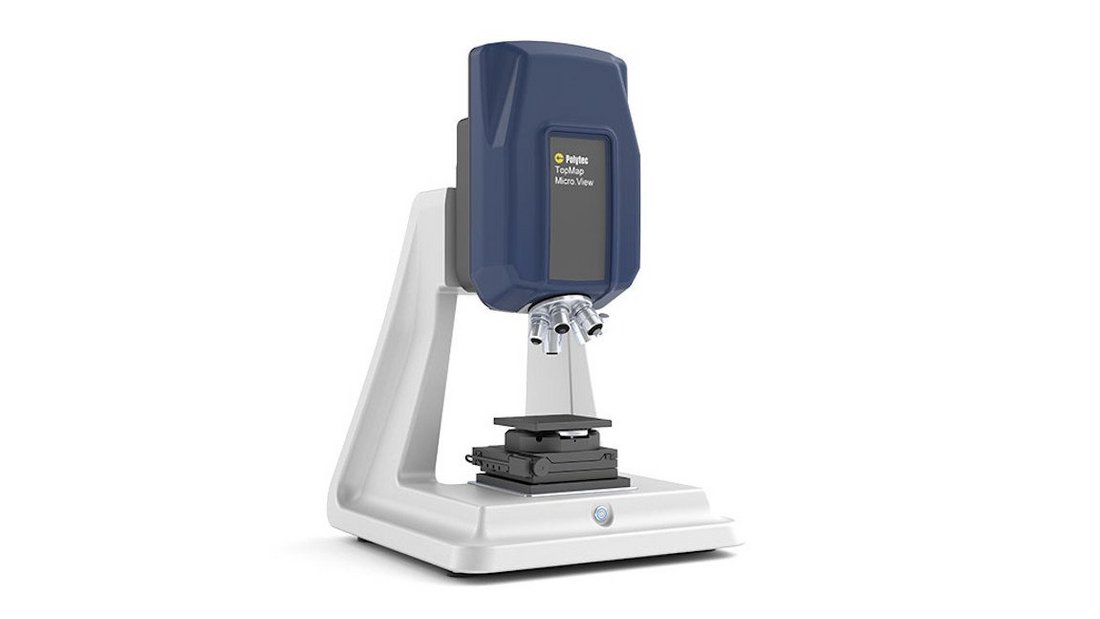

TopMap Micro.View

TopMap Micro.View® is an easy to use optical profiler in a compact table-top setup. Choose Micro.View® as the cost-effective inspection tool for examining precision-engineered surfaces down to the sub-nm range, for inspecting roughness, microstructures and more surface details. Custom objectives 0.6x to 111x and stage options allow for application-specific finetuning.

TopMap Micro.View+

TopMap Micro.View®+ is the next generation optical surface profiler in a modular design to measure challenging workpiece textures, surface finish and microstructures or MEMS with sub-nm resolution. Focus Finder and Focus Tracker assist in keeping samples focused at all times along the exceptionally large 100 mm Z range, with fully motorized positioning ready for both labs and automation. Challenge it now!

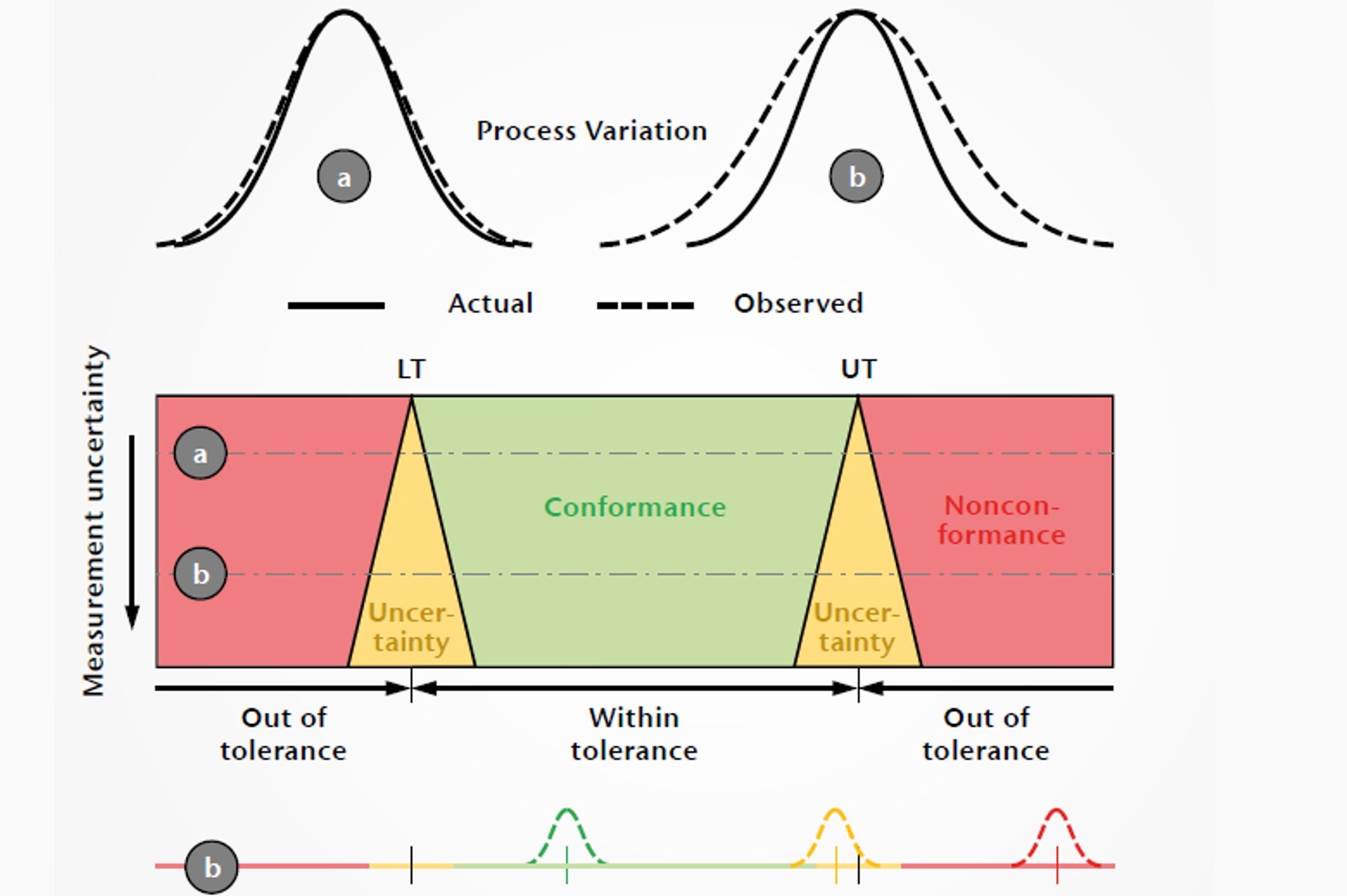

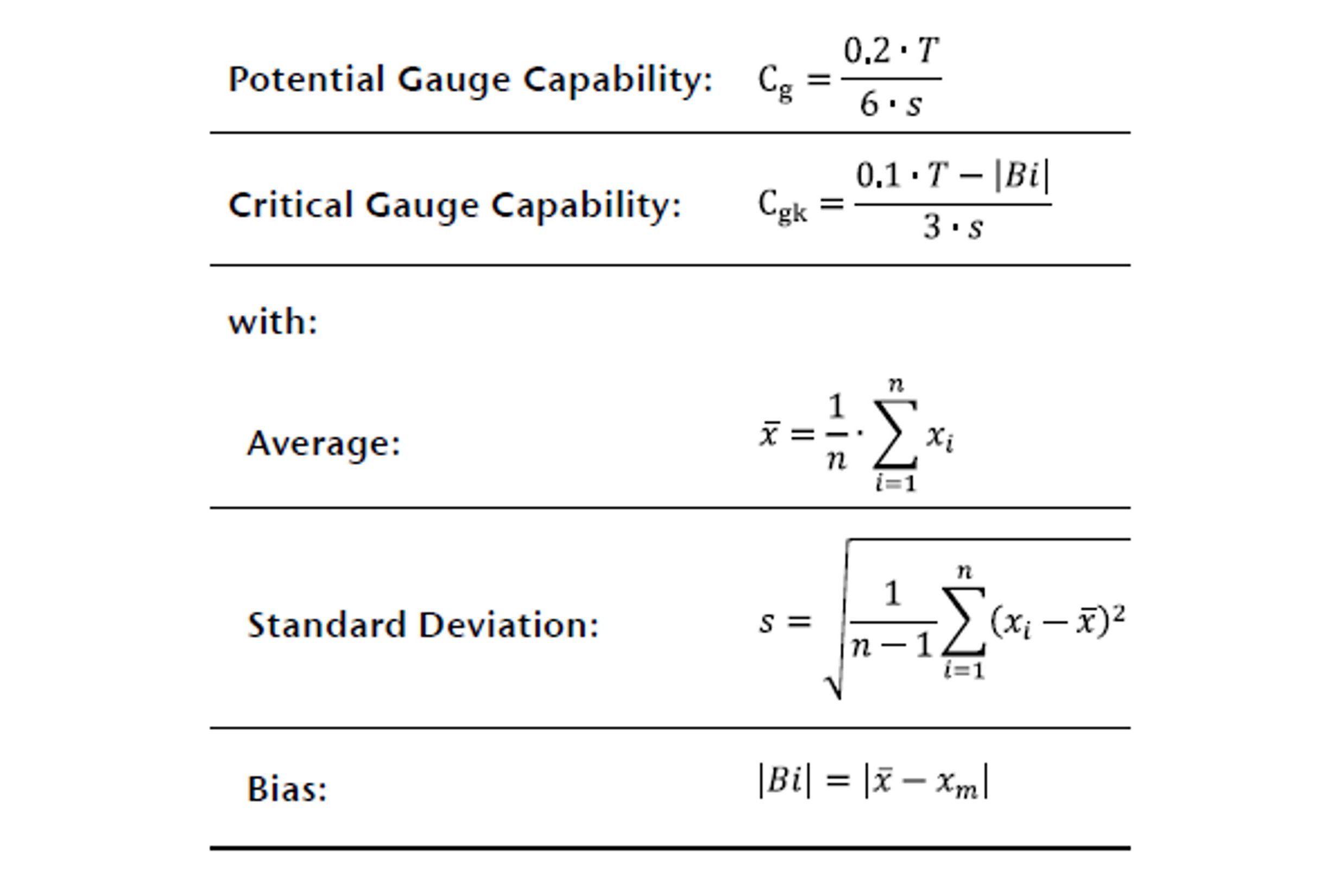

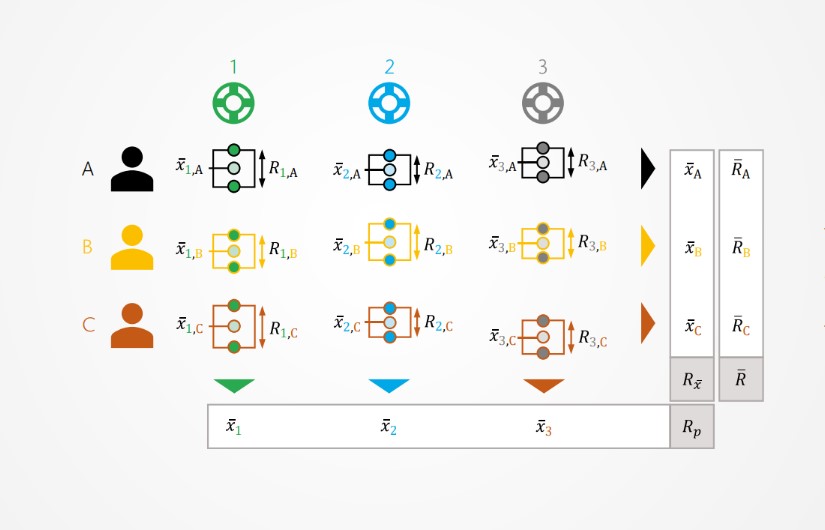

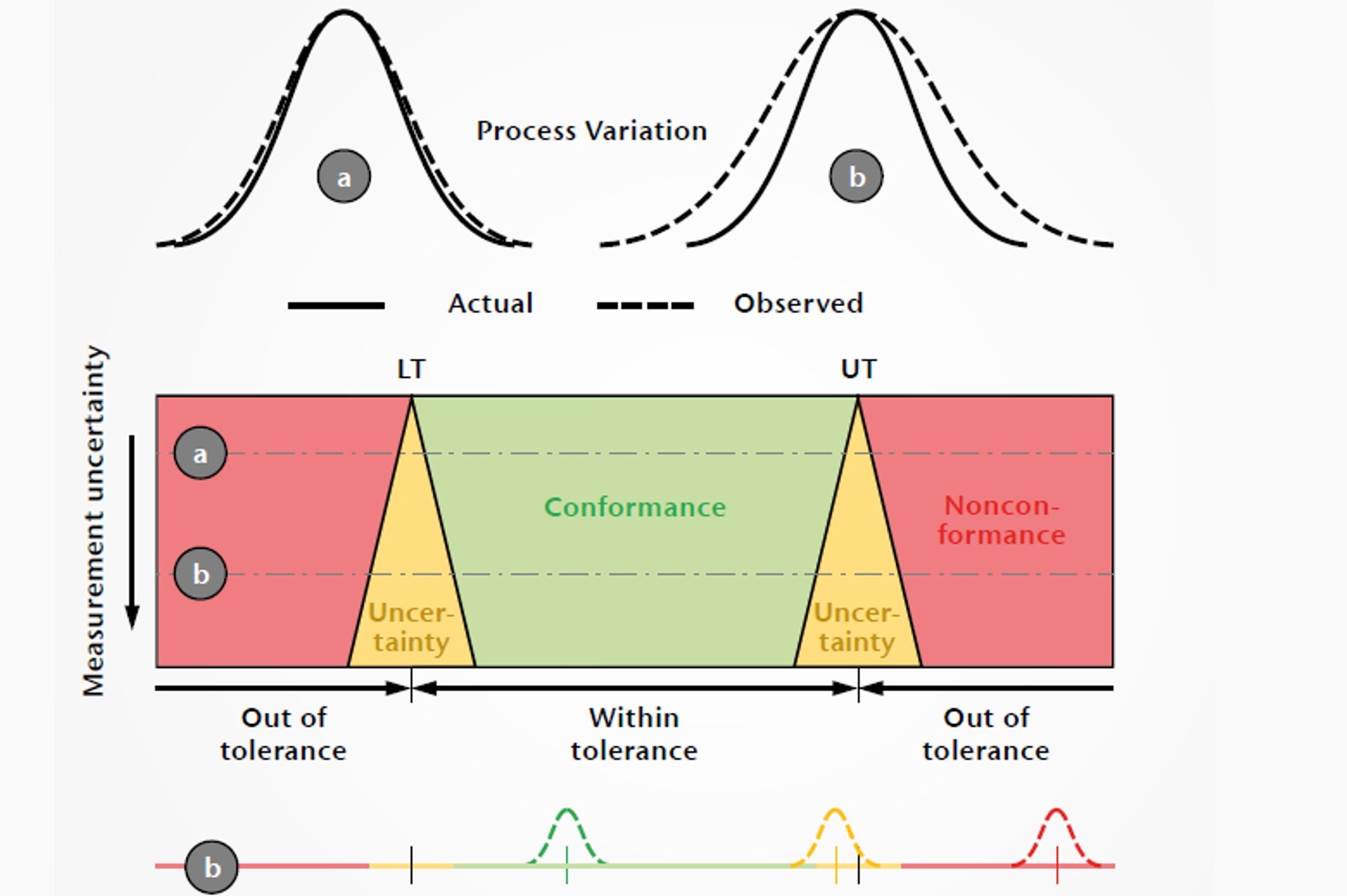

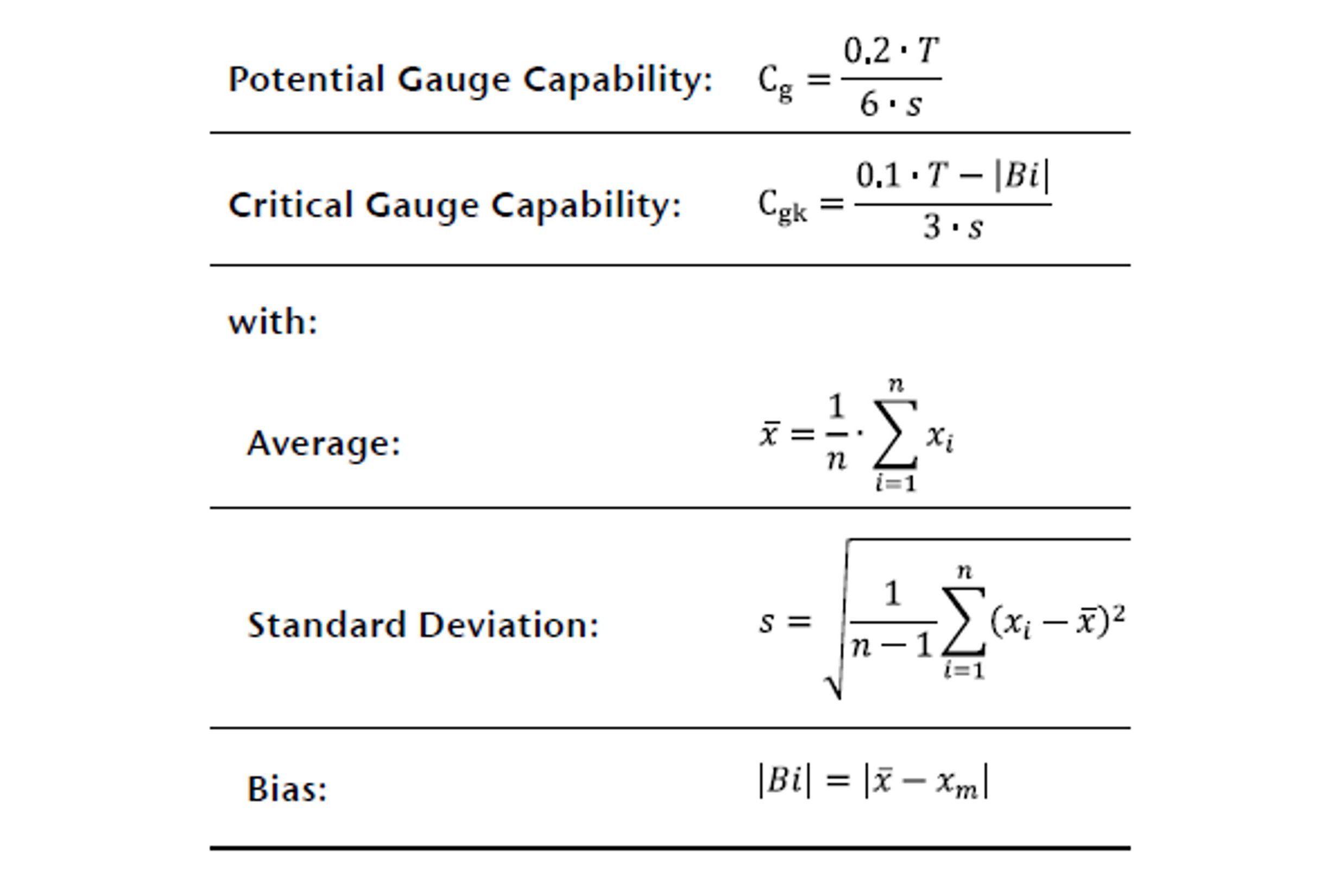

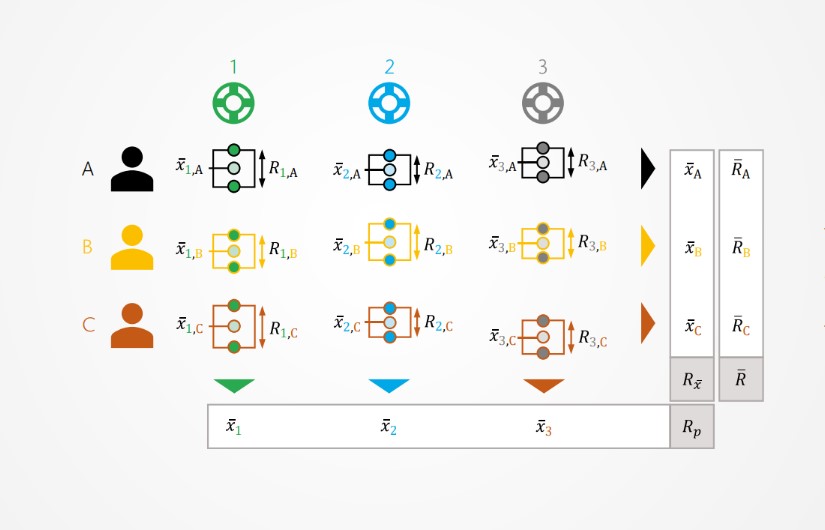

Free guide on how to: Measurement System Analysis

Every measurement - whether with tactile or optical surface profilers - is subject to uncertainty. The measured values obtained are the basis for quality-controlled production and are thus a key component of quality assurance. However, the correctness of any conclusion drawn by a measurement depends not only on the suitability of the parameter, but also on how accurately and how reliably the measured values reflect the real conditions. Only if the measured value can be determined with a sufficiently small uncertainty in relation to the tolerance of the characteristic, the measurement process is suitable for the inspection task. This paper describes approaches and helpful capability figures of Measurement System Analysis (MSA).

Read in the free guide how to deal with measurement uncertainty for your Quality Assurance!