Calibration and maintenance

If your laser Doppler vibrometer (LDV) laser head and controller have not been serviced or calibrated within the past 2 years or 2000 hours of use, they should have a complete calibration and check-up. Routine calibrations can eliminate problems with LDV laser heads that may have a low laser beam output which may be making it difficult to get a full signal level. This may be caused by dirty optics, improper handling, or an aging laser tube. Routine calibrations of LDV controllers verifies that the outputs are in conformance with their specifications.

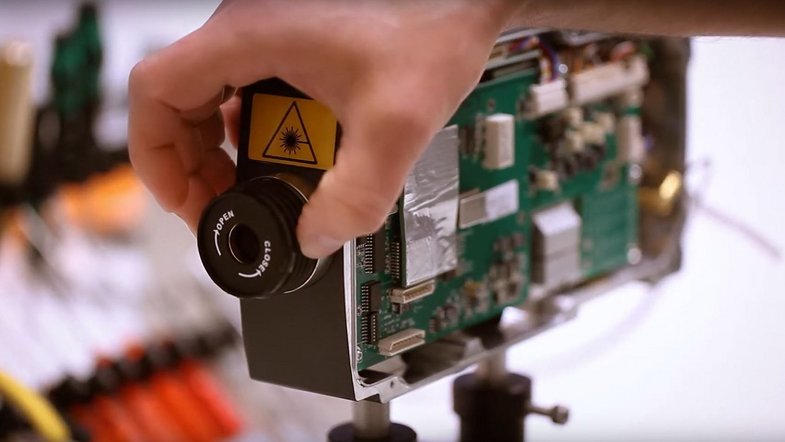

A complete calibration and check-up of the LDV laser head includes:

- Cleaning of optics

- Any necessary alignments and tuning of the optics

- An assessment of the integrity of the output of the laser

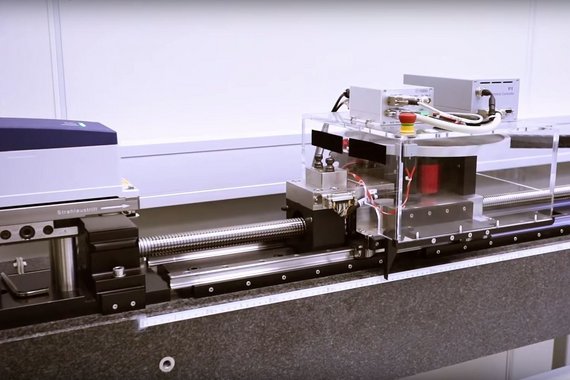

- End test on a calibrated shaker

- A certificate of calibration and compliance, valid for 2 years

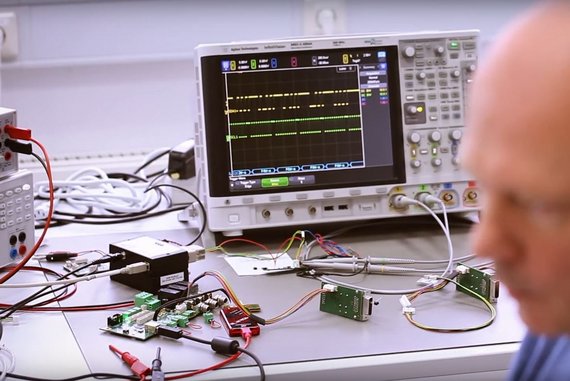

A complete calibration and check-up of the LDV controller includes:

- Cleaning of internal components to eliminate dirt and dust build up

- The use of DDS (Direct Digital Synthesis) technology to verify over a range of frequencies and amplitudes that the outputs are in conformance with their specifications

- A certificate of calibration and compliance, valid for 2 years

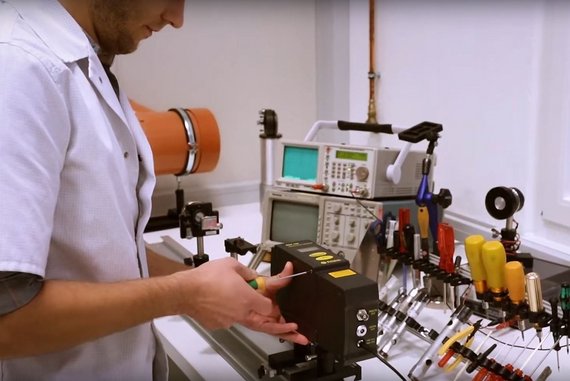

A PSV scanning vibrometer system calibration includes verification of the Data Management System.

Repair

If a component of your Polytec system unexpectedly becomes defective we provide fast and reliable repair with original spare parts. The evaluation fee is $600. Upon completion of an approved repair this fee will be applied directly to the final repair charges. A quote with the standard evaluation fee will be e-mailed to you with a return authorization number and a shipping address to ship your product to one of our Service Centers.