Durability testing, high cycle fatigue and noise identification

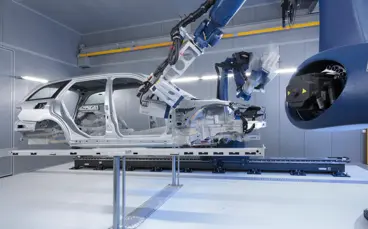

It is impossible to imagine modern vehicles without electronics. Not only do electronics control vehicles; they are increasingly powering them too. This is precisely why reliable electronics are critical for market success. Vibration and impact loads are therefore extensively tested prior to SOP.

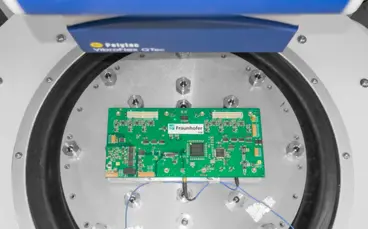

The non-contact vibration sensors from Polytec are ideal for dealing with these problems. The high-sensitivity laser technology reliably detects vibration-related weak points on printed circuit boards or individual components, right down to individual bond wires. Modal tests and order analyses quickly provide the right data for component, PCB, enclosure and attachment optimization.

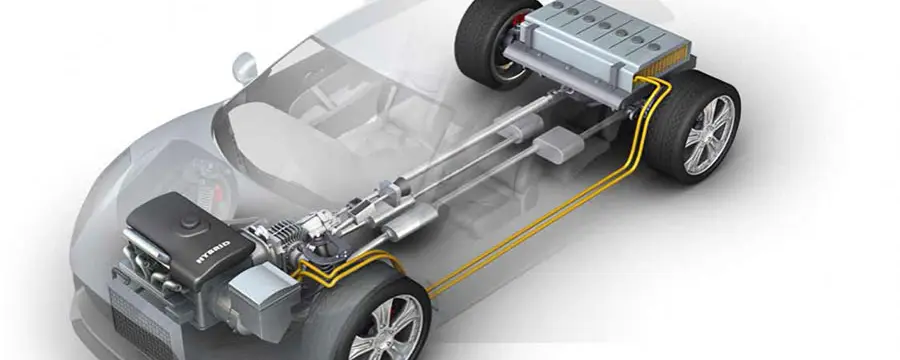

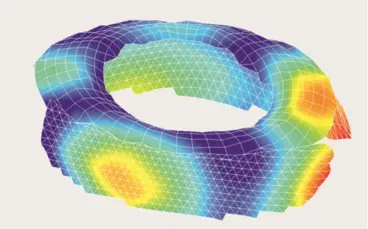

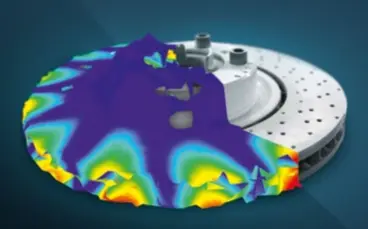

The additional noises produced by pumps, adjusting drives and fans can be heard much more clearly if the combustion engine is not being used as a masking noise factor in electric or hybrid vehicles running in electric mode. There is also the high-performance electronics, which add a new source of high acoustic sharpness to the vehicle acoustics. Laser vibrometers from Polytec enable clear 3D visualization and quantification of transfer paths into vehicle interiors and efficiently identify source of noise on electronics boards. Polytec laser Doppler vibrometers are the testing instruments of choice worldwide of OEM and tier 1 suppliers.

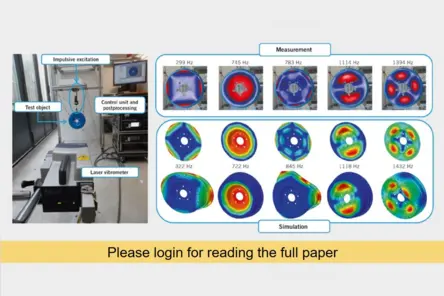

Vibration analysis in electric mobility (EV)

Wheel hub motors are advantageous for the packaging, but on the other hand they lead to new challenges in terms of noise development due to the installation position. The Otto von Guericke University in Magdeburg examined external rotor electric motors using operating vibration analysis with Polytec laser vibrometers in order to understand and optimize the component behavior and the resulting acoustics of wheel hub motors. Read the exclusive article with complete measurement results after a short registration.

Related products

VibroOne

The laser Doppler vibrometer VibroOne® is the one-box solution for non-contact vibration measurement up to 3 MHz. It is specifically designed for tightly packed setups, whether in research laboratories, challenging production environments or for non-contact analysis of tiny details on microstructures or biomedical probes. The optional inline HD+ camera helps positioning the laser precisely and provides proper test documentation.

VibroFlex

With the modular laser vibrometer VibroFlex, Polytec presents the superior flexibility in optical vibration measurement with a modular sensor solution up to 24 MHz that adapts to your needs: Add microscope objectives for observing tiny structures or measure large samples like machinery or motors from a safe distance. Discover acoustics and vibration phenomena in research and product development for a faster time-to-market or use it for reliable in-line inspections. Learn about how the patented multi-path interferometry QTec® provides an always stable signal level, 20 dB better SNR for faster and clearer results without post-processing.

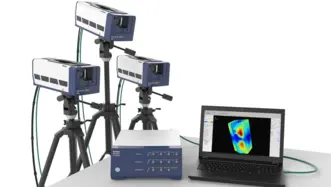

VibroScan QTec Xtra 3D

VibroScan QTec Xtra 3D measures vibrations triaxially in a new way - without contact, full-field and with unprecedented precision. With its groundbreaking multi-path interferometry, QTec® sets new standards in terms of optical sensitivity and interference immunity. The Xtra, based on an infrared (SWIR) laser is characterized by the highest optical sensitivity to guarantee highly accurate measurements even on demanding technical surfaces. VibroScan QTec Xtra 3D ensures maximum portability through integrated data acquisition and signal generator up to 32 MHz.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters—get in touch with us today.