The simulation of dynamic properties allows predictions for the subsequent product quality in terms of acoustics, comfort and durability. For this purpose, the simulation models are compared to real prototypes. Scanning Laser Doppler Vibrometers (SLDV) have been used for such prototype tests for decades. The new generation of PSV QTec® Scanning Vibrometers means that Polytec is introducing a brand-new laser technology which is a revolution in the full-field optical measurement of deflection shapes. Up to now, rough, technical surfaces could only be measured by accepting additional noise or by prior surface preparation.

Polytec now presents a significant value-add with QTec® in terms of an improved signal-to-noise ratio, especially on laterally moving or rotating sample surfaces, for distant or biological measurement objects. QTec® makes measurements up to 10x times faster, increasing the usable resolution by up to 20 dB while minimizing the influence of the laser’s angle of incidence. This gain in data quality and test efficiency is crucial to all applications where optical vibration measurement can already demonstrate its advantages as a non-contact, non-invasive test method.

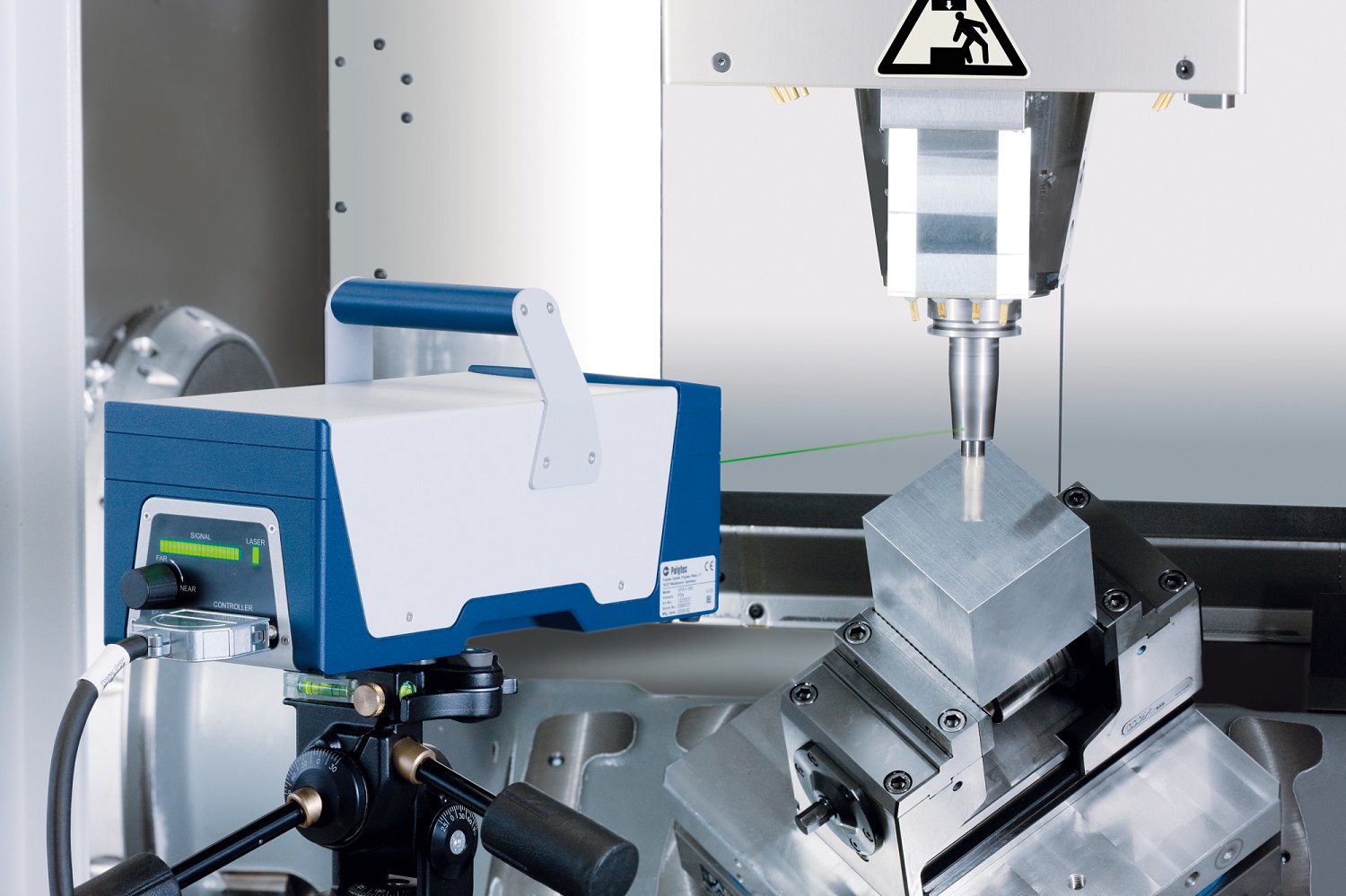

The 3D version of this SLDV is a well-established tool in research and development departments in the industry. Thanks to a freely positionable laser a nearly unlimited point density of the measurement grid is achievable, which brings test results very close to the quality of FE simulations. For comparing the test with simulation data, the visualized result can be directly displayed on basis of the 3D model. This is much more intuitive than purely quantitative methods or traditional wireframe modeling. PSV Scanning Vibrometers visualize the component dynamics directly in the software.

Laser light as the carrier of information avoids mass loading of the measurement object, allowing to measure e.g. light membranes or sheet metals in a completely non-invasive way. Laser vibrometry shows outstanding measurement linearity up to the MHz range, making it an essential testing method for medical technology and non-destructive testing.

So how does QTec® increase measurement data quality and test efficiency after all? Researchers at Polytec took a closer look at the interfering noise components of a typical measurement. The physics of coherent laser radiation introduce a significant noise component, especially when measuring on engineered surfaces. If a rough surface moves laterally to the laser beam due to vibration or rotation, it can happen that little or no light returns to the photodetector of the measuring device for a short time due to destructive interference of the light waves.

Since this effect depends on the particular perspective, QTec® vibrometers use multiple detection channels from slightly different perspectives and combine their best readings according to a patented method. This leads to an overall stable signal with a very high signal-to-noise ratio.

Enabling measurements on all kinds of different, imperfect or challenging sample surfaces, the field of application of the SLDV technology is extended to basic biomedical research for example, where non-contact measurement is indispensable.

Scanning Laser Doppler Vibrometry is an integral part of product development process chains. The new PSV QTec® Scanning Vibrometer makes the difference by providing unrivalled data reliability and meaningful results.

Further information: https://www.polytec.com/us/vibrometry/products/full-field-vibrometers/psv-qtec-scanning-vibrometer

Figure: Copyright: Polytec