Optical vibration measurement across industries

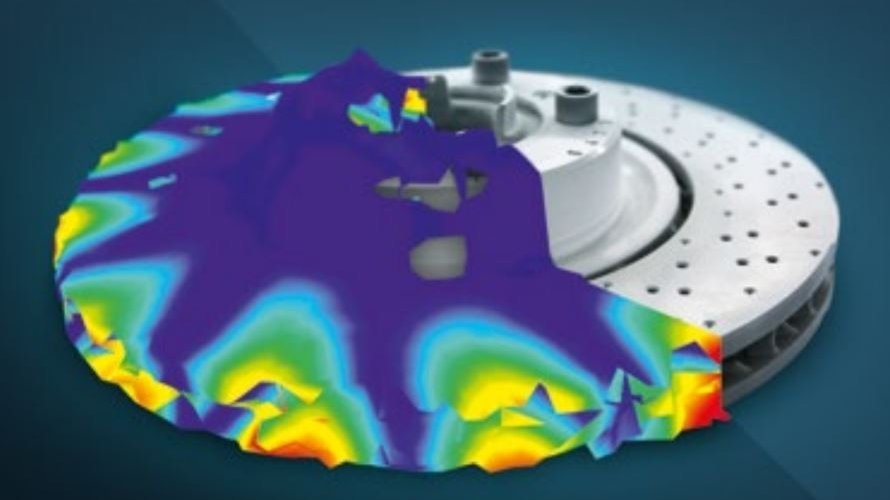

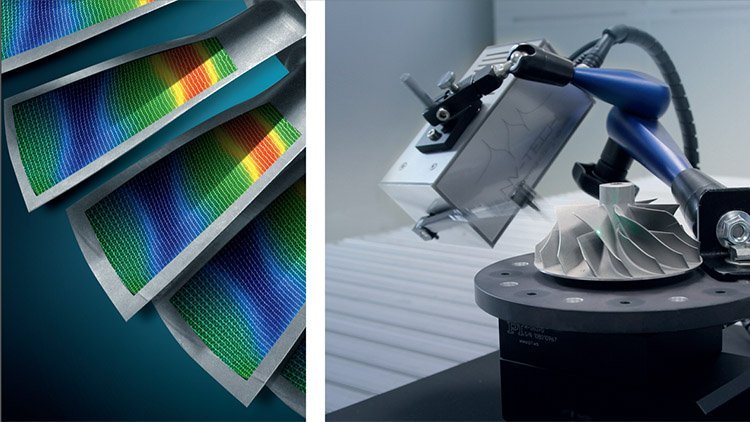

Understanding vibrating systems in nature and technology requires sophisticated, flexible and ideally non-invasive vibration measurement tools. Laser Doppler vibrometry has proven to be the most accurate and reliable method of vibration measurement. In industrial research and development, Polytec vibration measurement systems are used to study objects of many different sizes, ranging from entire car bodies, aircraft components, engines and buildings to tiny micro-machines and hard disk drive components. There are countless other research applications in mechanical engineering, acoustics and many other engineering-related disciplines. Measure remotely on red-hot surfaces, on rotating components, analyze high-frequency ultrasonic tools and fully understand the dynamic behaviour of the most complex and delicate structures in 3D. See how Polytec's vibration measurement technology helps to reveal the true vibration, acoustics and dynamics of vibrating structures.

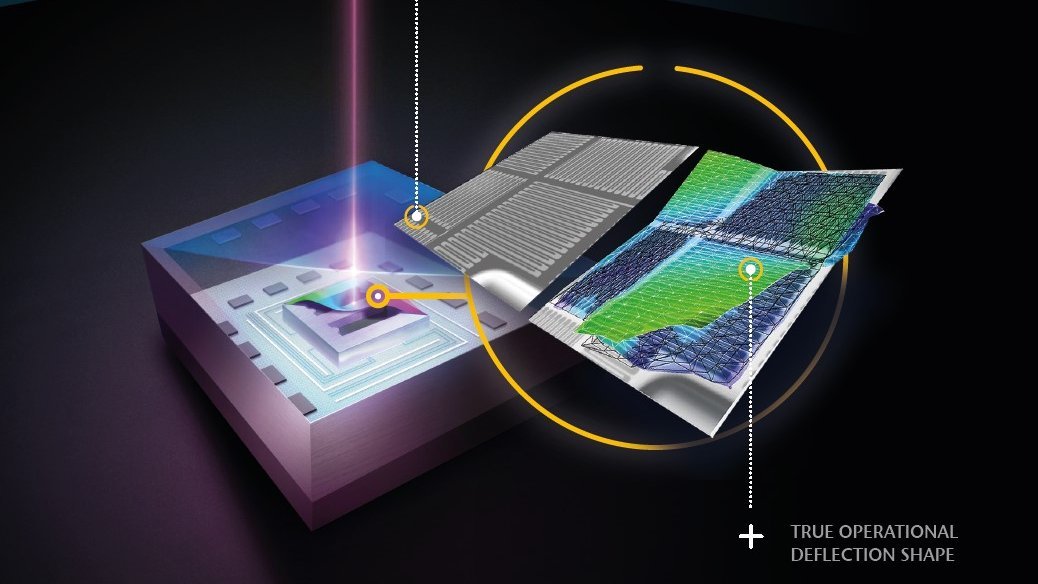

Laser vibrometry focusing on the small details

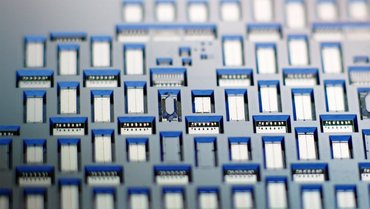

Characterize small and delicate structures in a non-contact way. Analyze vibration, acoustics and dynamics. Measure biomedical samples, electronics components and microstructures like MEMS by light, without mass-loading, and from DC up to the GHz range on a large bandwidth. Laser vibrometers focus on the small details, measuring deflection shapes for model validation. They assess the frequency response and determine resonance frequency, impulse response and Q factor. No matter how big or small – Polytec vibrometers measure it!

Have we spiked your interest in optical vibration measurement?

Applications of optical vibration measurement

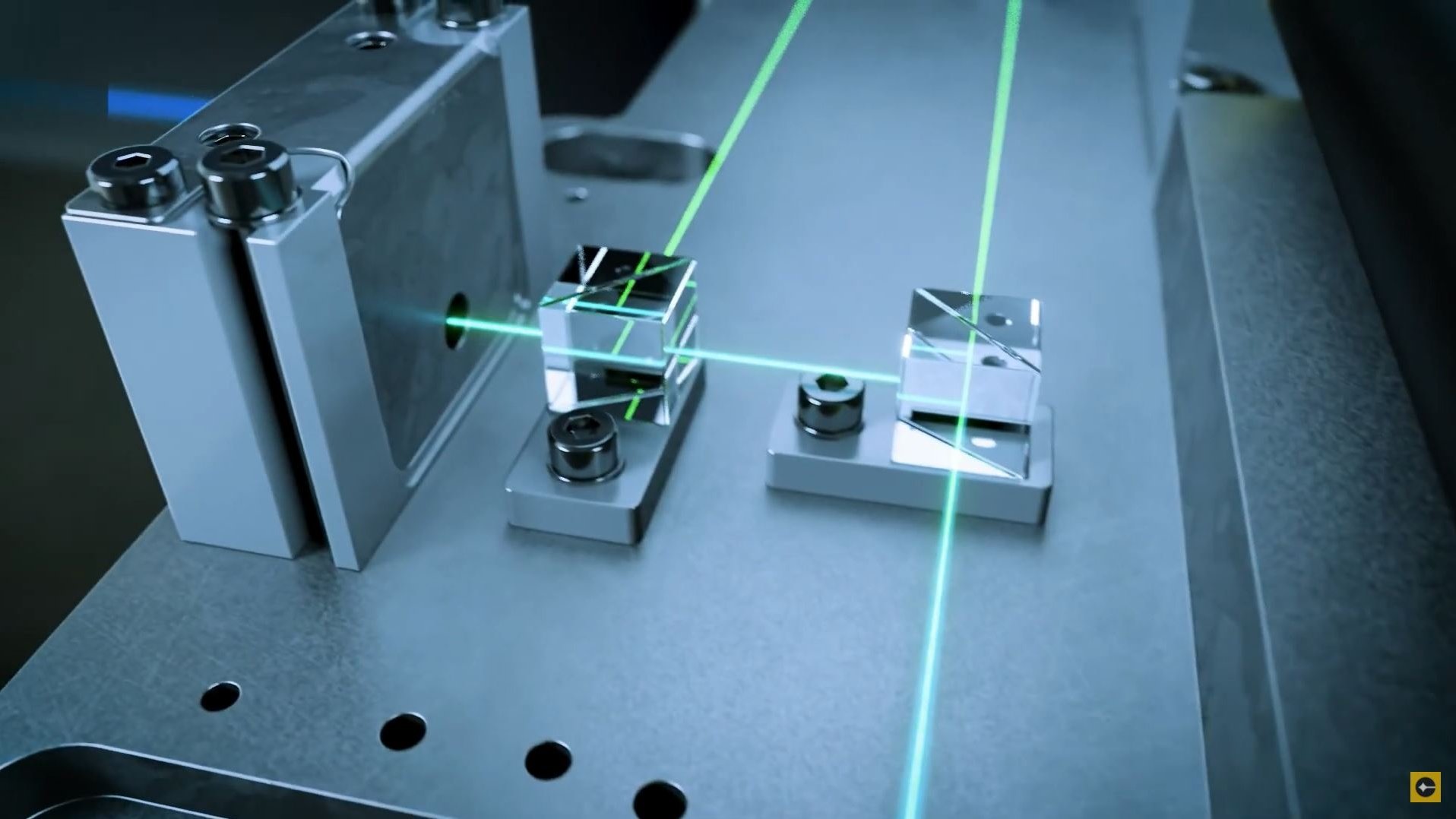

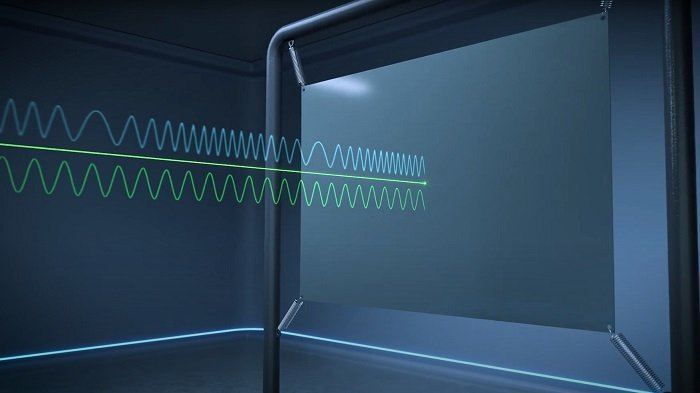

A pumping heart, wings vibrating, sounds are emitted and detected – life without vibrations is hard to imagine. Understanding vibrating systems in nature and technology requires sophisticated, flexible, and ideally non-invasive measurement tools. Recent innovations like the QTec® multi-path interferometry further push the limits.

Vibration measurement as free demo, feasibility study and off or onsite service?

How to measure vibrational velocity?

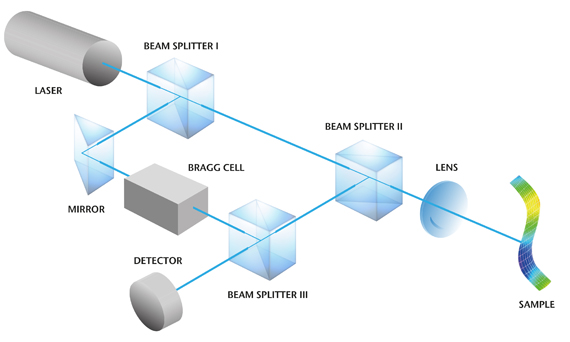

The frequency modulation of the light intensity is proportional to the vibration velocity. Whenever the measured vibrating object moves by half a wavelength of the HeNe laser (λ = 316 nm), the intensity will run through a full light-dark cycle. A light-sensitive sensor converts the changes in light intensity into an electronic signal. The frequency fD of these light-dark cycles is proportional to the speed v of the measured object as follows:

fD= 2 × v/ λ

Download the full whitepaper about the advantages of optical vibration measurement.