Acoustic quality control with laser precision

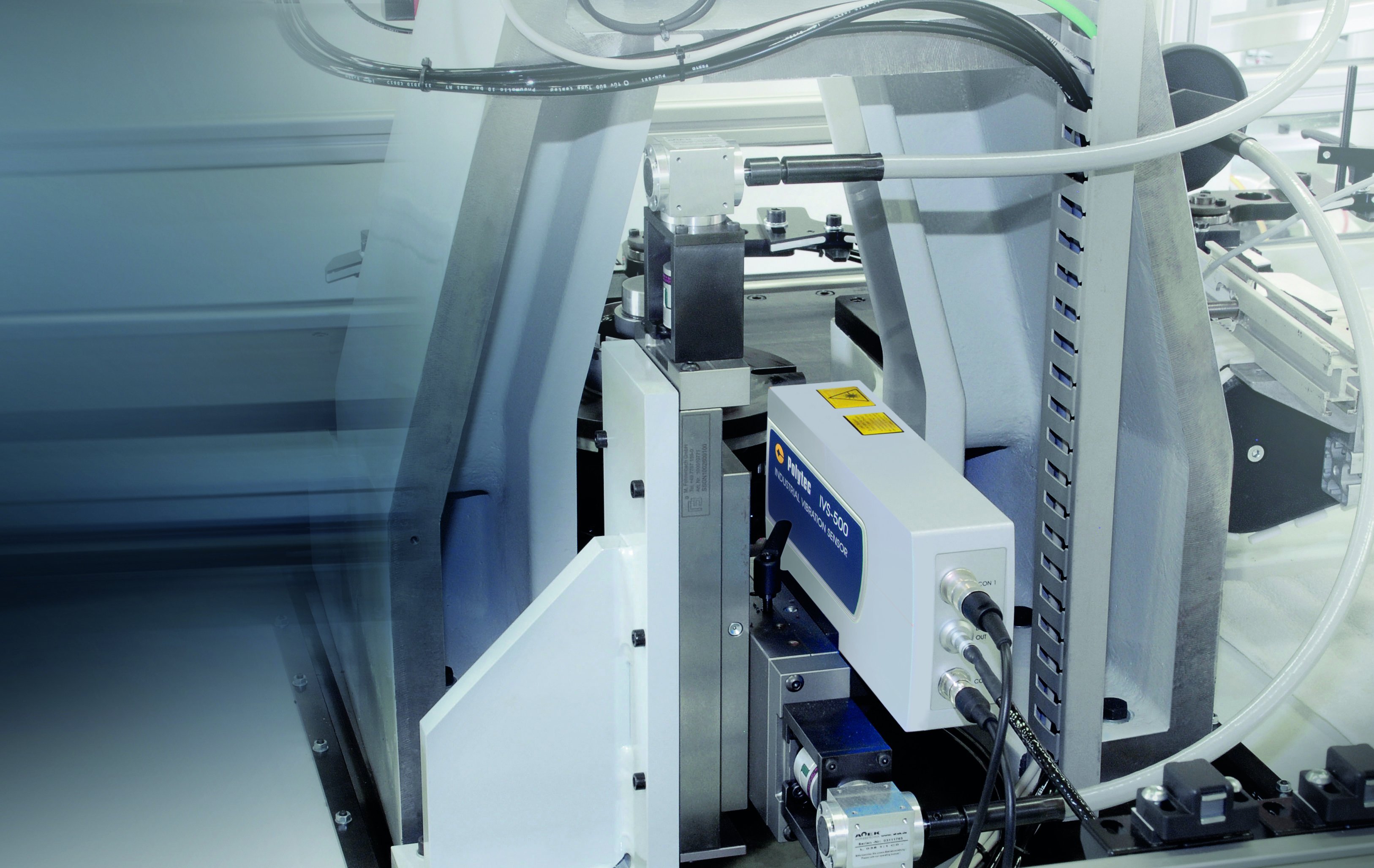

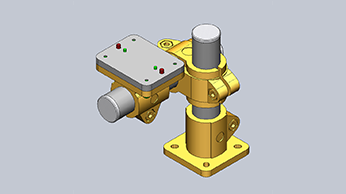

The IVS-500 Industrial Vibration Sensor is the key to fast acoustic quality inspection, structure-borne noise analysis and reliable pass-fail decisions. This laser vibration sensor measures reliably, in demanding industrial environments, without contact and therefore without wear and on virtually all surfaces. Optimize costs and yields by reducing false rejects in the production and assembly process.

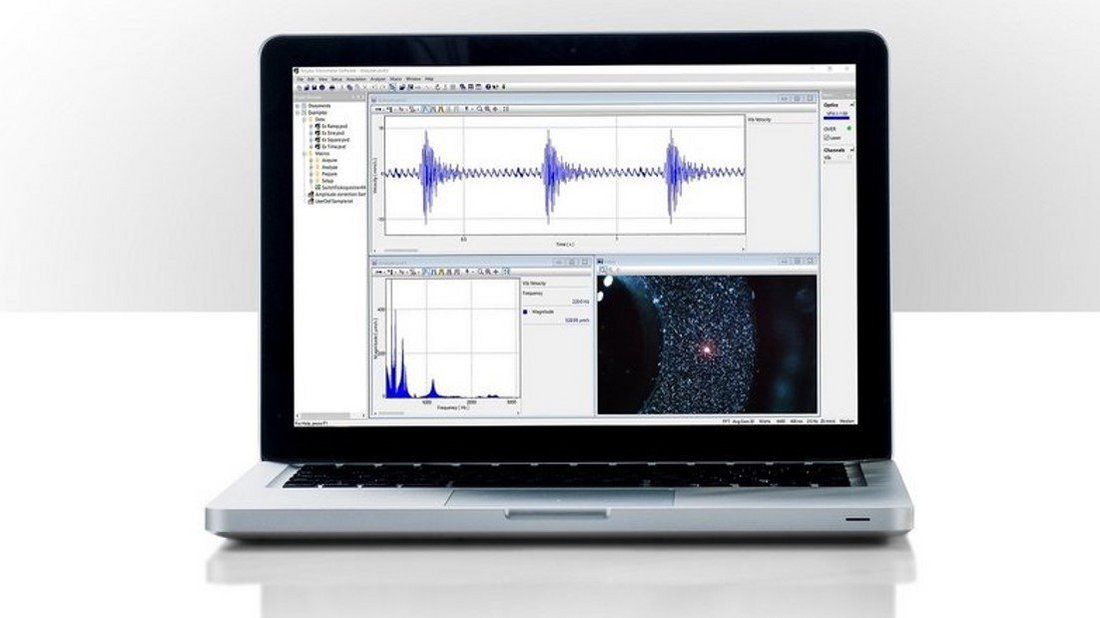

New signal outputs available: Choose between displacement signal, acceleration and velocity signal and directly process either analog or optionally digital measurement data.

Highlights

- Clear and repeatable pass/fail decisions for production testing

- Reliable, non-contact quality inspection with laser precision

- Flexible working distances up to 3 m with auto focus

- Versatile covering any application up to 100 kHz

- Robust and wear-free sensor technology

Easy in-line/ at-line integration and setup

- Vibration output as velocity, displacement and acceleration data

- Signal output analog and optionally digital

Acoustic quality control with laser precision

Become an expert: tips, tricks & video tutorials

The IVS-500 Industrial Vibration Sensor from Polytec is a dedicated and flexible measuring device for the vibroacoustic end-of-line test.

This exclusive section (login) provides an overview, the basics of optical acoustic testing using laser vibrometers including a technology benchmark, features tips & tricks in intuitive video tutorials for the use and handling of the IVS-500 Industrial Vibration Sensor - for starters, current users, integrators and experts.

Options and accessories

Optical Accessories

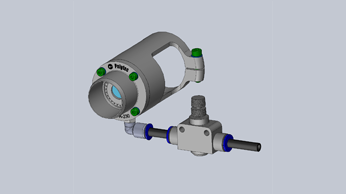

VIB-A-210 90° Deflection unit

VIB-A-220 Protective window

Protects the objective lens of the laser vibrometer from dust, oil and contamination. Tube around window for additional protection.

VIB-A-221 Protective window (flat)

Protects the objective lens of the laser vibrometer from dust, oil and contamination. Flat design for easy cleaning.

VIB-A-230 Air purge unit

For improved protection of the protective window from oil mist and dust.

VIB-A-240 Pneumatic beam shutter

Mechanically protects protective window from dust and contamination.

Tripods, Test Stands, Positioning Stages

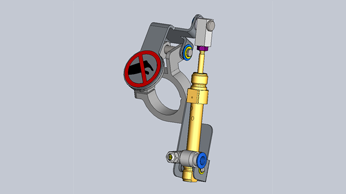

VIB-A-P07 Pan/Tilt Adjustable Mounting Plate

For installation in industrial production lines. Allows fine adjustment of the tilt and rotation angles by ± 1.3°.

VIB-A-P09 Alignment device

For installation in industrial production lines. Allows adjustment in 2 translational directions and 2 rotations (tip/tilt).

Software, Data Acquisition

IVS-500-Prog Programming Kit

Allows reconfiguration of IVS-500 factory settings

Miscellaneous

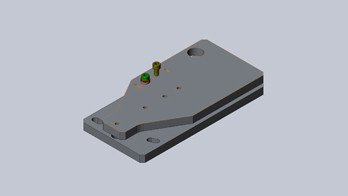

IVS-E-500 Junction Box

Rail mounting unit, providing interfaces and power to the IVS-500.

IVS-A-510 Signal Level Display

Handheld Unit for direct connection to IVS-500 Sensor or IVS-E-500 Junction Box.

VIB-A-310 Alignment tool

Allows adjustment of laser beam perpendicular to the object surface for best signal quality.

VIB-A-320 Folding ruler

Shows visibility maxima for optimal working distance.