Optimizing sensors for imaging ultrasonic measurement instrumentation

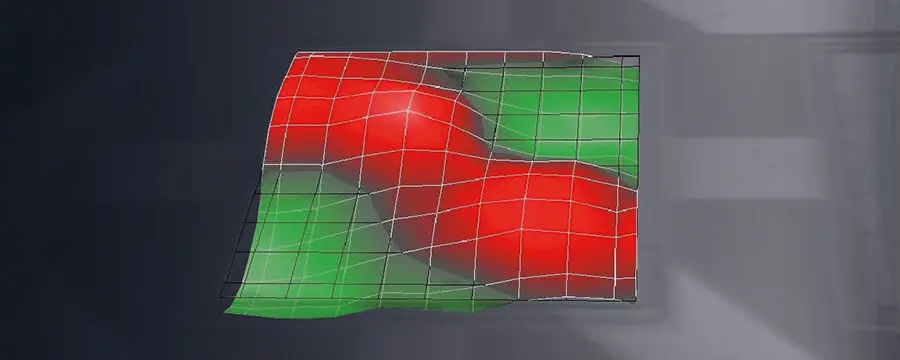

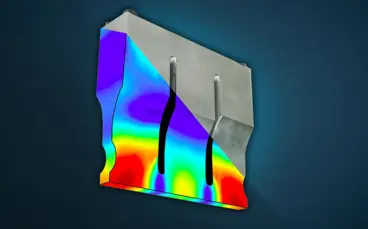

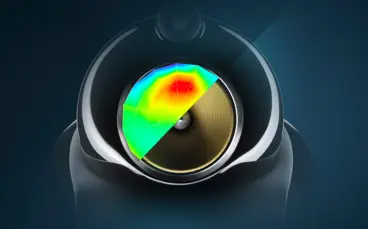

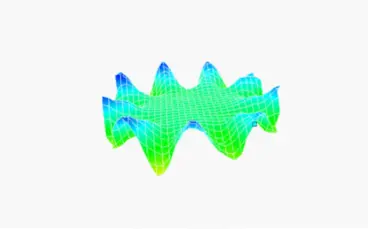

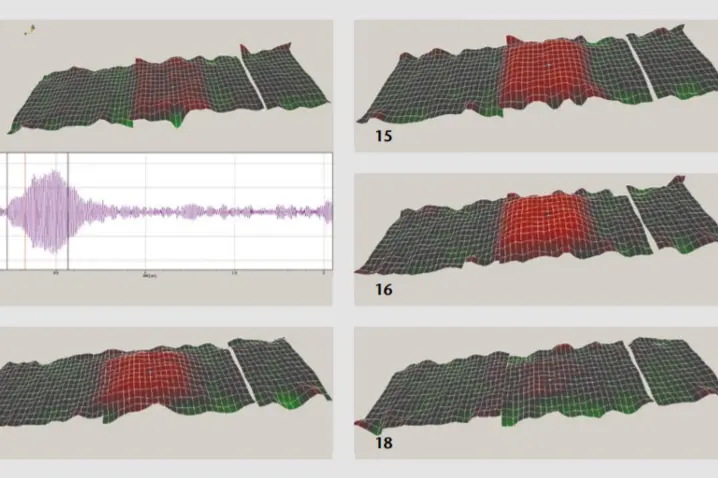

Nowadays an increasing number of micro-manufactured sensors, actuators and components vibrate at frequencies in the high MHz range. These include, for example, ultrasound sensors or transducers as used for imaging in medical applications. To test the functionality of these components, to check existing simulation models and to optimize the design of the systems, you have to measure their dynamic behavior. Laser Doppler vibrometry is one of the few available solutions for this. It allows for non-contact characterization across all frequencies – even for broadband excitation. The deflection shapes can be visualized in an impressive way. Crosstalk in arrays can be recorded and graphically illustrated, just like the timing of the individual array elements. Even transients and relaxation behavior can be examined with ease. Being an optical measurement method, laser vibrometry also enables you to perform measurements through transparent liquids, so ultrasonic transducers can be characterized in the actual application-oriented loading case.

Areal examination up to the Gigahertz regime

Determine the behavior of samples vibrating at high frequencies of up to 2.4 GHz with relative ease and great precision. Short measurement time and scanning entire areas at once is a significant advantage of the measuring method and finally improves the development process in particular. As an alternative to measuring the 3D sound field using a noise sensor installed in the room, you can now determine the resulting sound field simply with one or more scanned measurements and the subsequent simulation.

Related products

VibroScan QTec Xtra

VibroScan QTec Xtra measures vibrations in a new way - without contact, full-field and with unprecedented precision. With its groundbreaking multi-path interferometry, QTec® sets new standards in terms of optical sensitivity and interference immunity. The Xtra, based on an infrared (SWIR) laser is characterized by the highest optical sensitivity to guarantee highly accurate measurements even on demanding technical surfaces. VibroScan QTec Xtra ensures maximum portability through integrated data acquisition and signal generator up to 32 MHz.

VibroScan QTec Neo

VibroScan QTec Neo measures vibrations in a new way - without contact, full-field and with unprecedented precision. For the first time, QTec® technology has been successfully transferred from the infrared SWIR laser to the visible helium-neon laser. Featuring a small laser measuring spot, the precise helium-neon laser is suitable for measurements on the finest structures and even measures in and through water. QTec® always ensures a stable signal and the best signal-to-noise ratio. VibroScan QTec Neo ensures maximum portability with integrated data acquisition and signal generator up to 32 MHz.

MSA-650 IRIS Micro System Analyzer

The innovative and patented MSA-650 IRIS Micro System Analyzer with IR capability allows for measuring true MEMS dynamics up to 25 MHz by characterizing both in-plane and out-of-plane motions through silicon encapsulation without contact, without need for preparing nor decapping the device.

VibroFlex

With the modular laser vibrometer VibroFlex, Polytec presents the superior flexibility in optical vibration measurement with a modular sensor solution up to 24 MHz that adapts to your needs: Add microscope objectives for observing tiny structures or measure large samples like machinery or motors from a safe distance. Discover acoustics and vibration phenomena in research and product development for a faster time-to-market or use it for reliable in-line inspections. Learn about how the patented multi-path interferometry QTec® provides an always stable signal level, 20 dB better SNR for faster and clearer results without post-processing.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters—get in touch with us today.