Efficient validation with ultrasonics

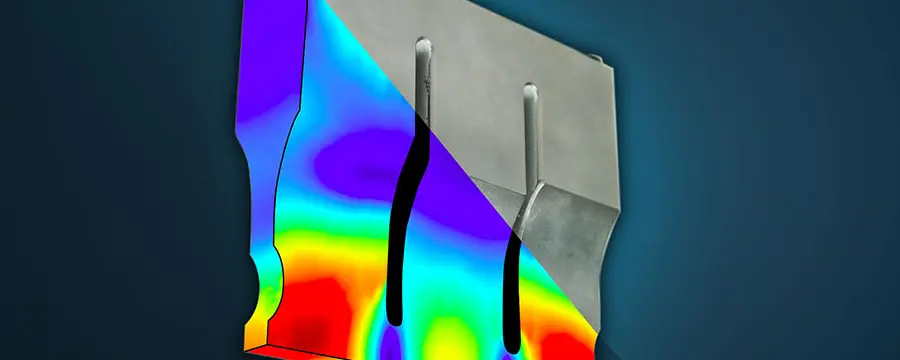

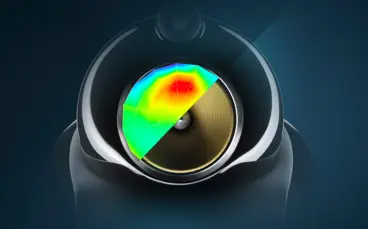

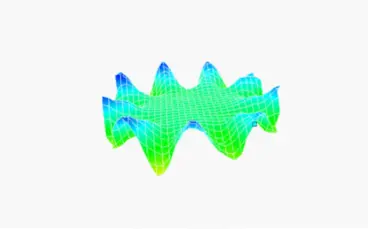

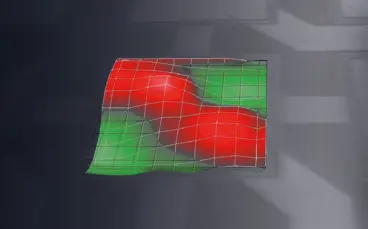

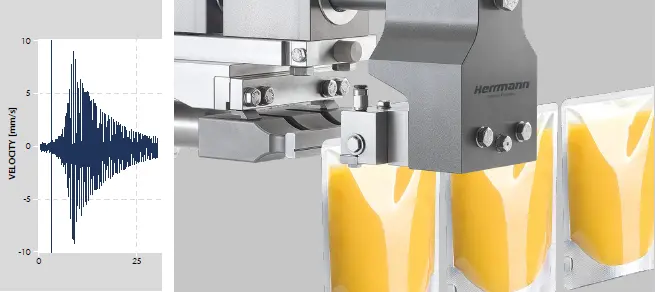

Laser Doppler vibrometers (LDV) help and simplify the development of efficient tools for ultrasonic processes. Laser scanning vibrometers from Polytec are indispensable for FE model validation and have proven their worth in many industries and applications, such as wire bonding, ultrasonic welding or ultrasonic food cutting. A good sonotrode design and coordination of the same to the transducer saves energy and guarantees a good result. The sonotrode’s operational deflection shapes can be determined directly and compared with the simulations using scanning laser Doppler vibrometers, thereby enabling reliable implementation of optimum efficiency levels. Even during the welding process, LDVs are capable of measuring the vibration amplitude right at the tool-workpiece contact, which not only gives you important information in the development phase, but also when deviations arise in the production process.

Ultrasonic laser testing

In addition to plastics technology, ultrasonics also enables metal ultrasonic welding or the joining of different materials, such as metal and fiber-reinforced plastics (CFRP). Wire bonding – which is fairly widespread in microelectronics contacting – is yet another application. Also, the determination of the relative velocity and displacement amplitudes by performing a differential measurement, which is necessary for forming a highly stress-resistant joint is a popular application. Last but not least, laser vibration testing allows reliable calculation of the vibration amplitudes under operating conditions – excellent for assessing the ultrasonic welding process.

Experimental modal analysis on sonotrodes for ultrasonic bonding

Related products

VibroScan QTec Xtra

VibroScan QTec Xtra measures vibrations in a new way - without contact, full-field and with unprecedented precision. With its groundbreaking multi-path interferometry, QTec® sets new standards in terms of optical sensitivity and interference immunity. The Xtra, based on an infrared (SWIR) laser is characterized by the highest optical sensitivity to guarantee highly accurate measurements even on demanding technical surfaces. VibroScan QTec Xtra ensures maximum portability through integrated data acquisition and signal generator up to 32 MHz.

VibroScan QTec Neo

VibroScan QTec Neo measures vibrations in a new way - without contact, full-field and with unprecedented precision. For the first time, QTec® technology has been successfully transferred from the infrared SWIR laser to the visible helium-neon laser. Featuring a small laser measuring spot, the precise helium-neon laser is suitable for measurements on the finest structures and even measures in and through water. QTec® always ensures a stable signal and the best signal-to-noise ratio. VibroScan QTec Neo ensures maximum portability with integrated data acquisition and signal generator up to 32 MHz.

VibroOne

The laser Doppler vibrometer VibroOne® is the one-box solution for non-contact vibration measurement up to 3 MHz. It is specifically designed for tightly packed setups, whether in research laboratories, challenging production environments or for non-contact analysis of tiny details on microstructures or biomedical probes. The optional inline HD+ camera helps positioning the laser precisely and provides proper test documentation.

VibroFlex

With the modular laser vibrometer VibroFlex, Polytec presents the superior flexibility in optical vibration measurement with a modular sensor solution up to 24 MHz that adapts to your needs: Add microscope objectives for observing tiny structures or measure large samples like machinery or motors from a safe distance. Discover acoustics and vibration phenomena in research and product development for a faster time-to-market or use it for reliable in-line inspections. Learn about how the patented multi-path interferometry QTec® provides an always stable signal level, 20 dB better SNR for faster and clearer results without post-processing.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters—get in touch with us today.