White-light interferometry

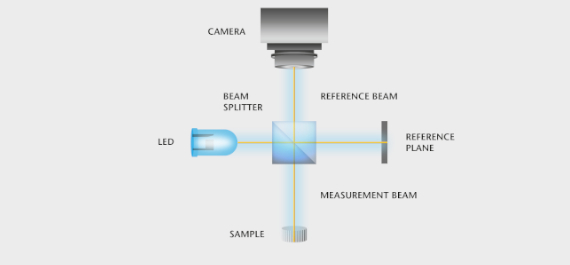

Modern white-light interferometers use the interference effects that occur when the light reflected from the sample is superimposed with the light reflected by a high-precision reference mirror. The measurement method is based on the principle of Michelson interferometry, where the optical configuration (image) contains a light source with a coherence length in the μm range.

Technology guide: compare pros & cons of optical surface metrology approaches

Find out more about the strengths and limitations of these four common surface measurement methods in the technology comparison, regarding vertical and lateral resolution, application sweet spots on smooth surfaces or roughness measurement, with or w/o stitching

- White-light interferometry

- Confocal microscopy

- Focus variation

- Chromatic confocal sensors

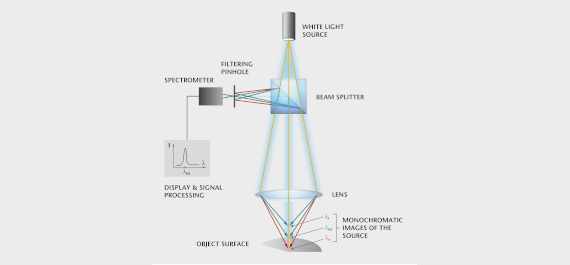

Chromatic confocal technology

Chromatic confocal technology for the optical measurement of distance, roughness line profiling and thickness has been established as one of the mature methods available to industry and research. Chromatic confocal sensors from Polytec base on a measurement principle explained in the following.

Surface parameters

Evaluating form parameters like flatness, parallelism and waviness and characterizing a surface structure based on its texture, roughness profile and more are the fundamental values prodvided by surface metrology for a reliable quality control in the lab and in production environments. See some examples of what TopMap surface metrology can measure for you.